GaN-ZnO solid solution nanowire and preparation method and application thereof

A nanowire and solid solution technology, applied in chemical instruments and methods, crystal growth, from chemically reactive gases, etc., can solve problems such as large grain size, limited photocatalyst solar spectral response range, and many crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

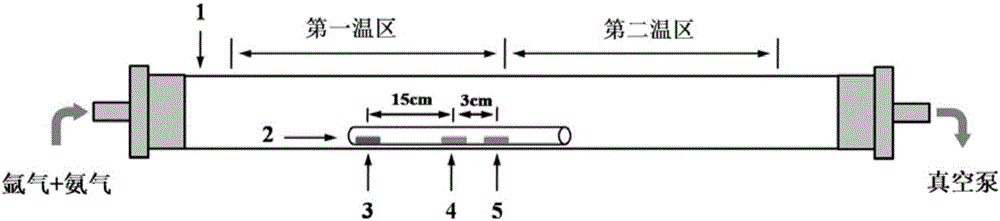

[0079] The preparation process of GaN-ZnO solid solution nanowires in this embodiment is as follows:

[0080] (1) By mass ratio GaN:Ga 2 o 3 :ZnO is 1:1:6, respectively weigh 62.5mg GaN, 62.5mg Ga 2 o 3 and 375mgZnO, after mixing and grinding evenly, the first raw material is obtained and put into a quartz boat;

[0081] (2) Take 50mg ZnO and 50mg graphite respectively by mass ratio ZnO:graphite is 1:1, after mixing and grinding uniformly, obtain the second raw material, place in another quartz boat;

[0082] It can be seen that the ratio of the total mass of the first raw material to the total mass of the second raw material is 5:1;

[0083] (3) Put the quartz boat with the first raw material, the quartz boat with the second raw material, and the silicon wafer substrate with the gold film deposited on the surface into a small quartz tube (30 cm in length and 2 cm in diameter) with one end sealed and one end open. In the process, the quartz boat containing the first raw m...

Embodiment 2

[0094] Except that step (1) is different, other preparation methods and conditions are the same as in Example 1.

[0095] Step (1) of the present embodiment is:

[0096] (1) By mass ratio GaN:Ga 2 o 3 :ZnO is 1:1:10, weigh 41.6mg GaN, 41.6mg Ga 2 o 3 and 416.8mg ZnO, after mixing and grinding uniformly, the first raw material is obtained, which is put into a quartz boat.

[0097] It is easy to know that the ratio of the total mass of the first raw material to the total mass of the second raw material in this embodiment is 5:1.

[0098] The mole percentage of ZnO in the GaN-ZnO solid solution nanowires obtained on the substrate in this embodiment is 84%.

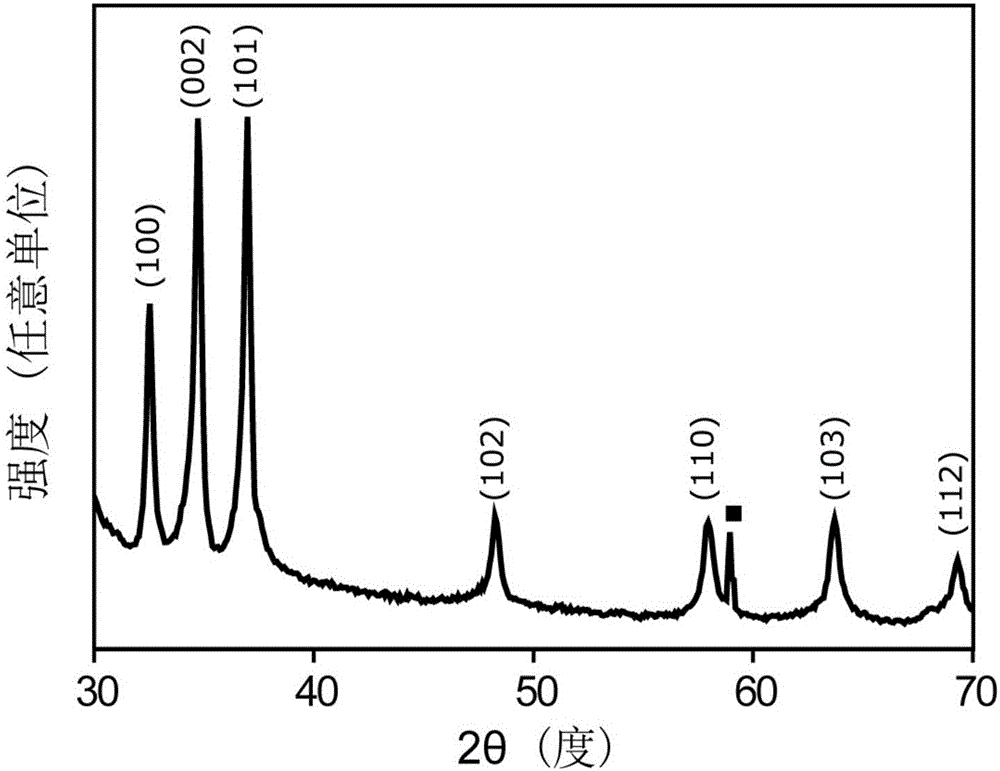

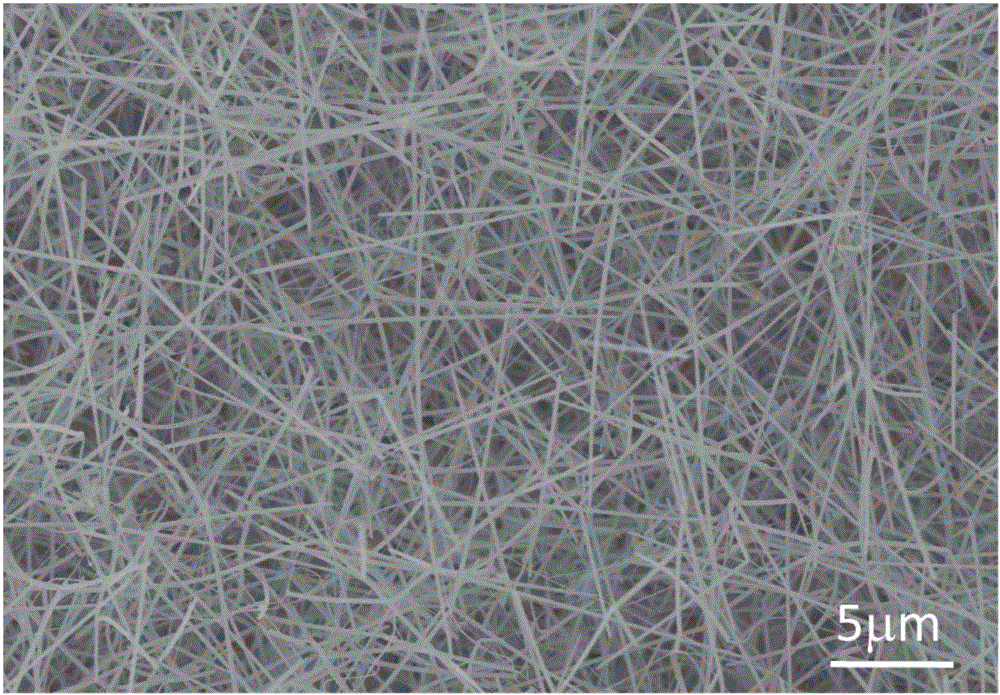

[0099] The morphology and structure of the GaN-ZnO solid solution nanowires prepared in this example are the same as those in Example 1. The solid solution nanowires are uniform in size, with an average diameter of 50 nm to 150 nm and a length of 5 μm to 50 μm; good crystallization and no structural defects.

[0100] ...

Embodiment 3

[0102] Except that the content of each component in the first raw material in step (1) is different, other preparation methods and conditions are the same as in Example 1.

[0103] Step (1) is in the present embodiment:

[0104] (1) By mass ratio GaN:Ga 2 o 3 : ZnO is 1:1:10, respectively weigh 37.5mg GaN, 37.5mg Ga 2 o 3 and 375mg of ZnO, after mixing and grinding evenly, the first raw material was obtained and put into a quartz boat.

[0105] It can be seen that the ratio of the total mass of the first raw material to the total mass of the second raw material is 4.5:1.

[0106] The morphology and structure of the GaN-ZnO solid solution nanowires prepared in this embodiment Example 1, the solid solution nanowires are uniform in size, with an average diameter of 50 nm to 150 nm and a length of 5 μm to 50 μm; good crystallization and no structural defects.

[0107] The mole percentage of ZnO in the GaN-ZnO solid solution nanowires obtained on the substrate in this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com