A kind of preparation method of rare earth doped gadolinium oxysulfide fluorescent powder

A technology of doping gadolinium oxysulfide and rare earth, which is applied in the field of material science, can solve the problems of high product cost and difficulty in purifying sulfate, and achieves the effect that the technical solution is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

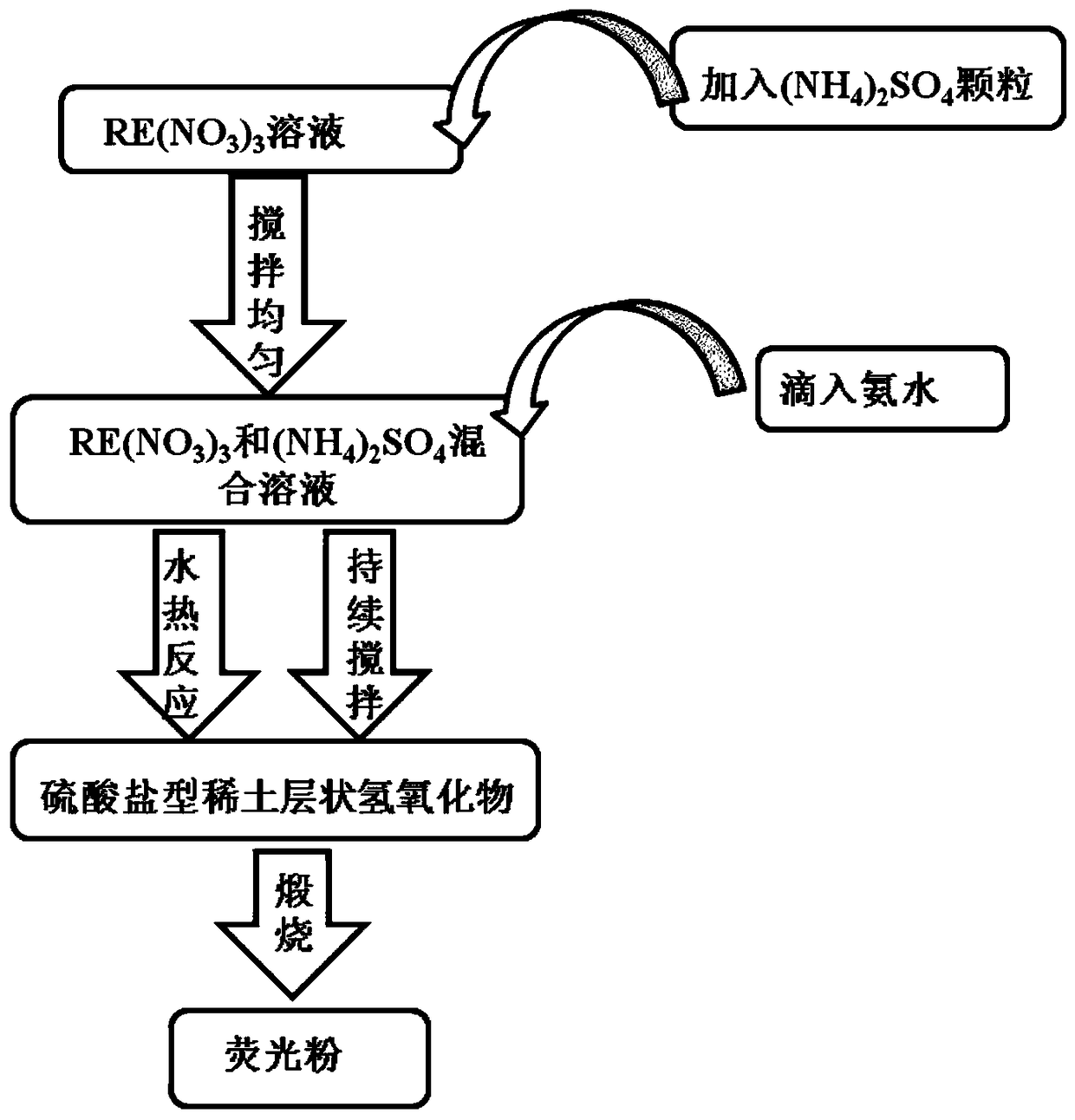

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of rare earth-doped gadolinium oxysulfide fluorescent powder, comprising the following steps:

[0052] (1) Gd(NO 3 ) 3 ·6H 2 O and Tb(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred at room temperature to obtain RE 3+ The concentration is 0.1mol / L RE(NO 3 ) 3 solution; where, in molar ratio, Gd 3+ :Tb 3+ =99:1;

[0053] (2) Dissolve 0.8g ammonium sulfate in 0.1mol / L RE(NO 3 ) 3 In solution, RE(NO 3 ) 3 The volume of the solution is 60mL, stirred for 15min, at 4°C, continued to stir and added ammonia water dropwise to adjust the pH value to 9.0 to obtain a suspension; wherein, by molar ratio, sulfate: RE 3+ =1:1;

[0054] (3) The suspension was continuously stirred and reacted at 4°C for 4 hours to obtain a reaction product;

[0055] (4) Centrifuge the reaction product, add water to wash three times, then add absolute ethanol to wash once, and dry at 50°C to obtain an amorphous white powder precursor-sulfate-type rare earth ...

Embodiment 2

[0058] A preparation method of rare earth-doped gadolinium oxysulfide fluorescent powder, comprising the following steps:

[0059] (1) Gd(NO 3 ) 3 ·6H 2 O and Tb(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred at room temperature to obtain RE 3+ The concentration is 0.1mol / L RE(NO 3 ) 3 solution; where, in molar ratio, Gd 3+ :Tb 3+ =99:1;

[0060] (2) Dissolve 0.8g ammonium sulfate in 0.1mol / L RE(NO 3 ) 3 In solution, RE(NO 3 ) 3 The volume of the solution is 60mL, stirred for 15min, at 30°C, continued to stir and added ammonia water dropwise, adjusted the pH value to 7.0, to obtain a suspension; wherein, in molar ratio, sulfate radical: RE 3+ =1:1;

[0061] (3) react the suspension with continuous stirring at 30° C. for 1 hour to obtain the reaction product;

[0062] (4) Centrifuge the reaction product, add water to wash three times, then add absolute ethanol to wash once, and dry at 70 ° C to obtain a white powder precursor - sulfate-type rare earth...

Embodiment 3

[0065] A preparation method of rare earth-doped gadolinium oxysulfide fluorescent powder, comprising the following steps:

[0066] (1) Gd(NO 3 ) 3 ·6H2 O and Tb(NO 3 ) 3 ·6H 2 O was added to deionized water and stirred at room temperature to obtain RE 3+ The concentration is 0.1mol / L RE(NO 3 ) 3 solution; where, in molar ratio, Gd 3+ :Tb 3+ =99:1;

[0067] (2) Dissolve 0.8g ammonium sulfate in 0.1mol / L RE(NO 3 ) 3 In solution, RE(NO 3 ) 3 The volume of the solution is 60mL, stirred for 20min, at 25°C, continued to stir and added ammonia water dropwise, adjusted the pH value to 7.0, to obtain a suspension; wherein, by molar ratio, sulfate radical: RE 3+ =1:1;

[0068] (3) Move the suspension to a reaction kettle, and conduct a hydrothermal reaction at 100° C. for 72 hours. After the reaction, cool naturally to room temperature to obtain a reaction product;

[0069] (4) Centrifuge the reaction product, add water to wash three times, then add absolute ethanol to wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com