Ultrasonic flaw detection device and ultrasonic flaw detection method

A flaw detection device, ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, temperature recording methods, etc., can solve problems such as pipe circumference deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

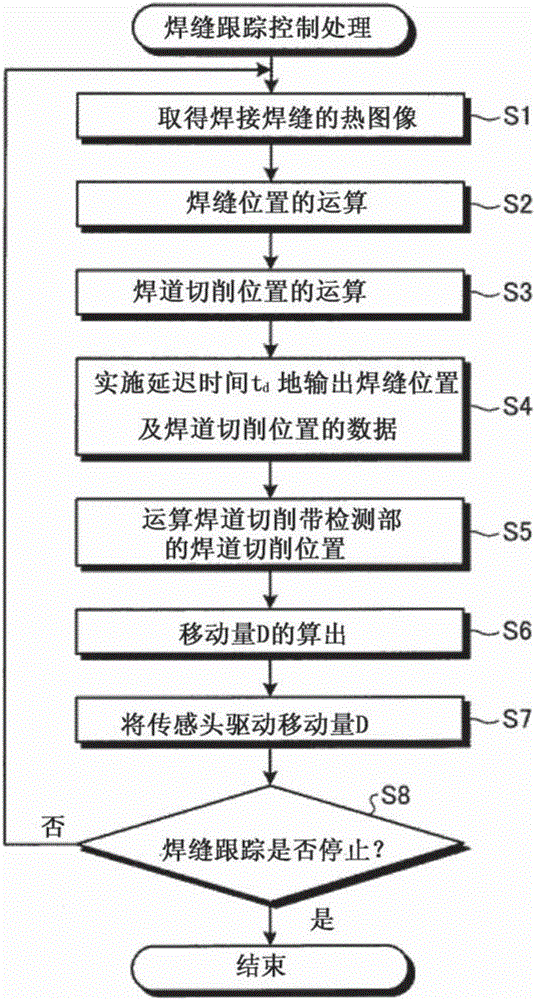

[0036] Hereinafter, the configuration and operation of an ultrasonic flaw detection device according to an embodiment of the present invention will be described with reference to the drawings.

[0037] 〔structure〕

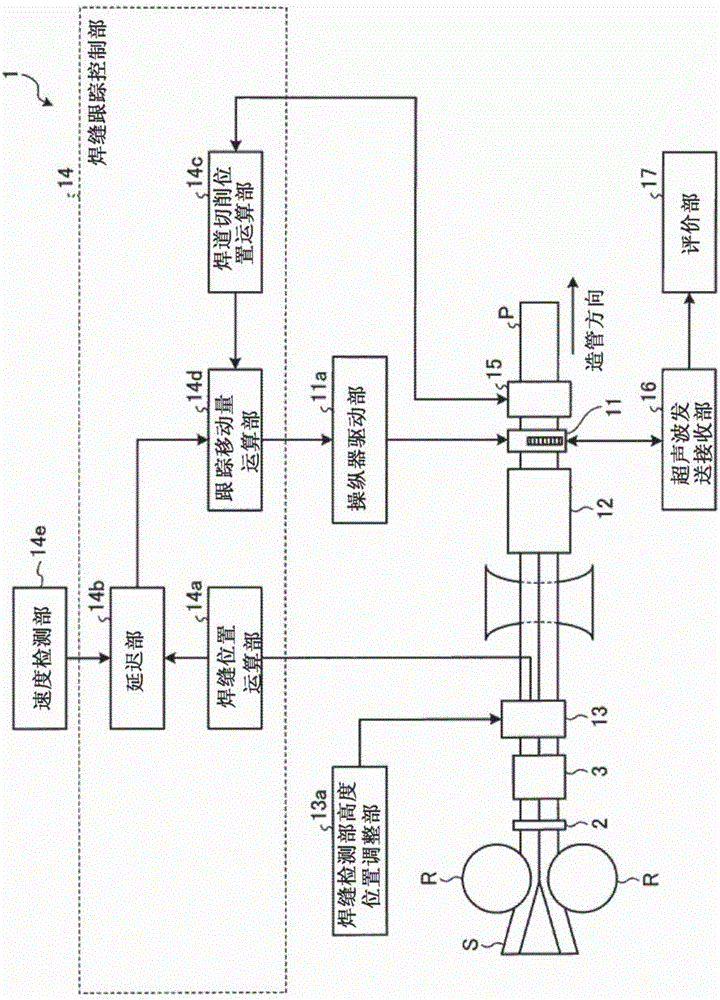

[0038] First, refer to figure 1 , figure 2 , and the structure of the ultrasonic flaw detection apparatus according to one embodiment of the present invention will be described.

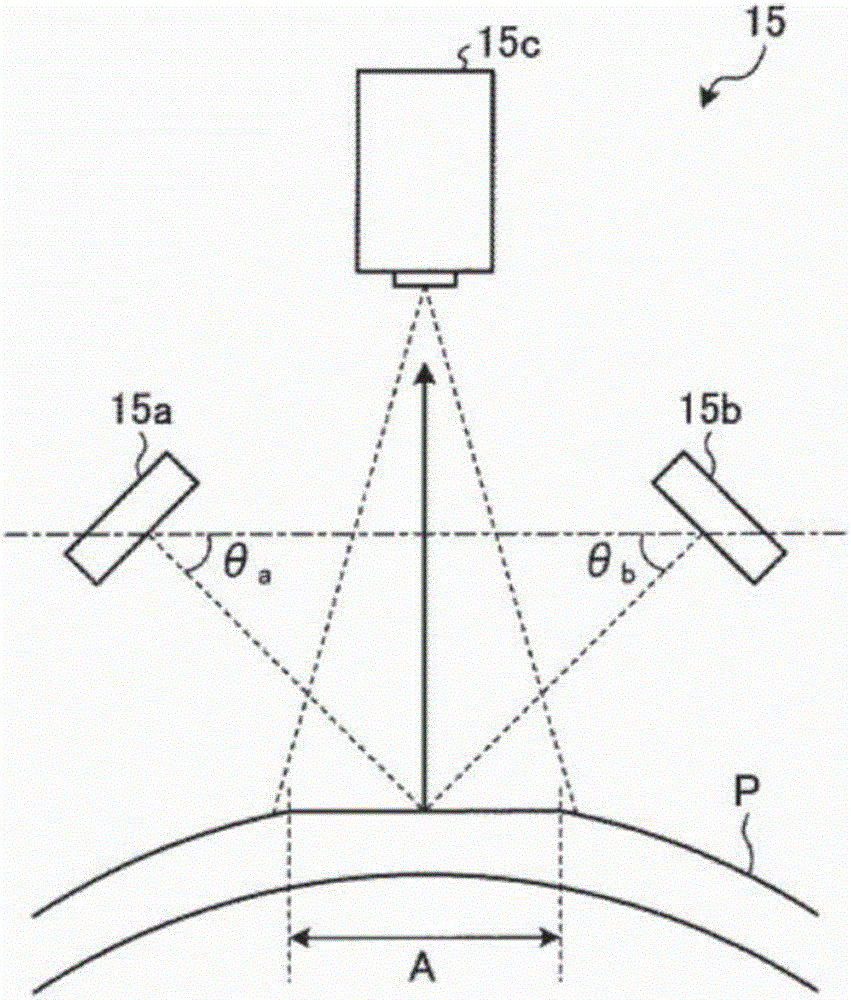

[0039] figure 1 It is a schematic diagram showing the overall structure of an ultrasonic flaw detection device according to an embodiment of the present invention. figure 2 yes means figure 1 A schematic diagram of the structure of the weld bead cutting zone detection section shown.

[0040] Such as figure 1As shown, the ultrasonic flaw detection device 1 according to one embodiment of the present invention is a device for ultrasonic flaw detection of a welded seam portion of an electric resistance welded steel pipe P made of a steel plate S formed into a tubular shape by rolls R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com