Ultrasonic motor with multiple axially laminated stators

An ultrasonic motor and multi-stator technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of single structure and difficult expansion of ultrasonic motors, and achieve Effects of improving frictional driving ability, improving working life and reliability, and high energy efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

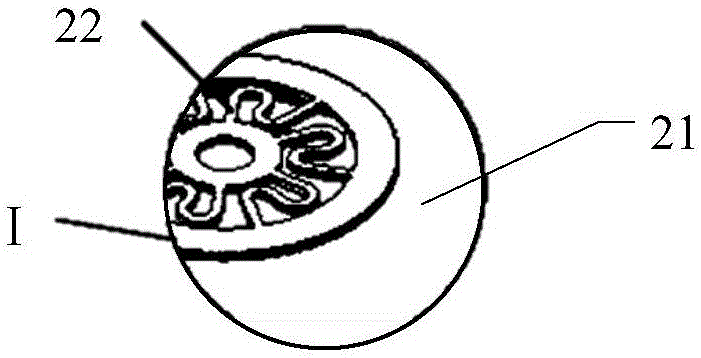

[0054] Such as Figure 1~Figure 4 As shown, an ultrasonic motor with axially laminated multiple stators includes a stator 1, a rotor 2 and an output shaft 3. The number of the stator 1 is two, the number of the rotor 2 is three, and the output The shaft 3 is one; the rotor 2 and the stator 1 are stacked in sequence. The rotor 2 includes a first rotor 201, a second rotor 202, and a third rotor 203; the stator 1 includes a first stator 101 and a second rotor. Two stators 102, the output shaft 3 passes through the first rotor 201, the first stator 101, the second rotor 202, the second stator 102, and the third rotor 203 in sequence, and then is fixedly connected with the nut 4, and the stator 1 drives the rotor 2 Rotation forms power output; each stator 1 corresponds to two rotors 2, and the middle rotor 2 is shared by the second rotor 202, that is, it is connected to the first stator 101 above and the second stator 102 below it.

[0055] Each stator 1 includes a hollow stator plat...

Embodiment 2

[0065] On the basis of embodiment 1, this embodiment is different from embodiment 1 in that the four-phase driving method is adopted. The arrangement rule and signal connection method of piezoelectric ceramic elements 13 on the stator ring 12 on the pads are different from those in embodiment 1. Specifically:

[0066] Such as Image 6 As shown, the piezoelectric ceramic element 13 and the electrodes include 4 sets of standing wave driving units, namely unit a, unit b, unit c, and unit d, each unit includes two piezoelectric ceramic elements on the front of the stator ring 12 13 and the two piezoelectric ceramic elements 13 on the reverse side of the stator ring 12, the piezoelectric ceramic elements 13 are arranged in sequence according to unit a, unit b, unit c, and unit d, and are cyclically arranged on the front and back surfaces of the stator ring 12;

[0067] In the unit a, unit b, unit c, and unit d, the polarized positive poles 131 of the two piezoelectric ceramic elements 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com