Driving mechanism of steel band driving roller in plastic film casting machine

A technology of plastic film and driving mechanism, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy. It can solve problems such as high risk, difficulty in practical use, and increased difficulty in installation and debugging, so as to eliminate transmission gap or hysteresis and ensure stability and consistency. performance, and the effect of improving the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

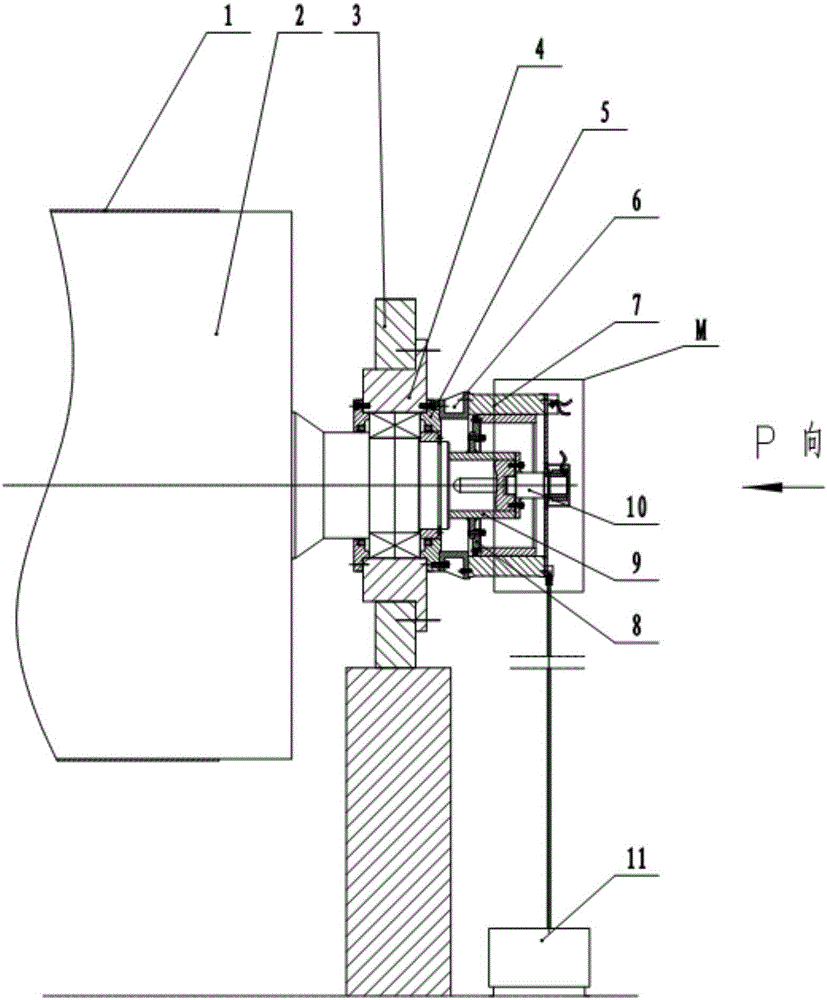

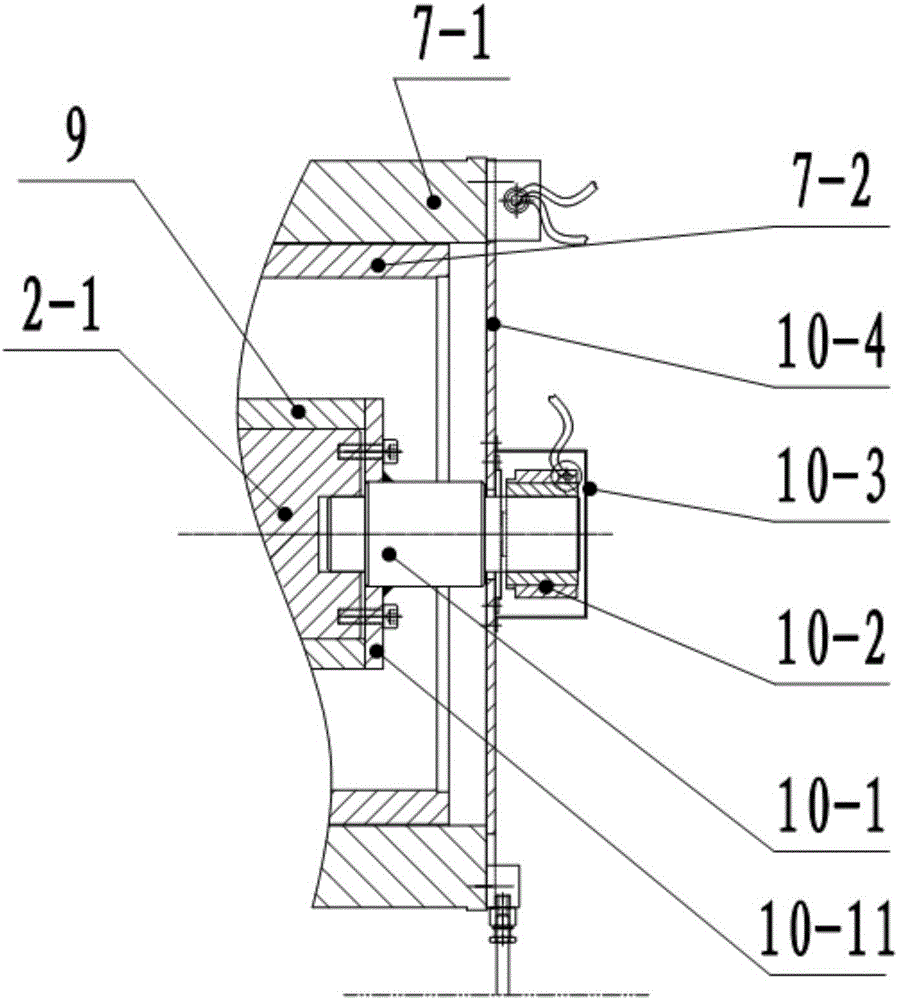

[0019] The embodiment of the driving mechanism of the steel belt drive roller in the plastic film casting machine of the present invention is for example Figure 1 to Figure 3 As shown, it includes steel belt 1, drive roller 2, tension roller, frame 3, torque motor 7, double-sided flange seat 6, transition flange 8, connecting sleeve 9, encoder assembly 10 and water cooling unit 11.

[0020] The tension force F of the steel belt 1 surrounds the drive roller 2 and the tension roller. The shaft ends 2-1 on the left and right sides of the drive roller 2 are installed on the left and right bearing housings 4 through bearings. The left and right bearings The base 4 is fixed on the base 3 on the left and right sides of the casting machine. The torque motor 7 is located at the shaft end 2 - 1 on one side of the driving roller 2 . The bearing seat end cover 5 is fixedly connected to the bearing seat 4, one side of the double-sided flange seat 6 is connected to the bearing end cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com