A semi-automatic strapping device

A semi-automatic, equipment-based technology, applied in the direction of electrical components, manufacturing wiring harnesses, circuits, etc., can solve the problems of uneven quality, low efficiency, and high labor intensity of binding, and achieve the effects of ensuring binding quality, improving efficiency, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

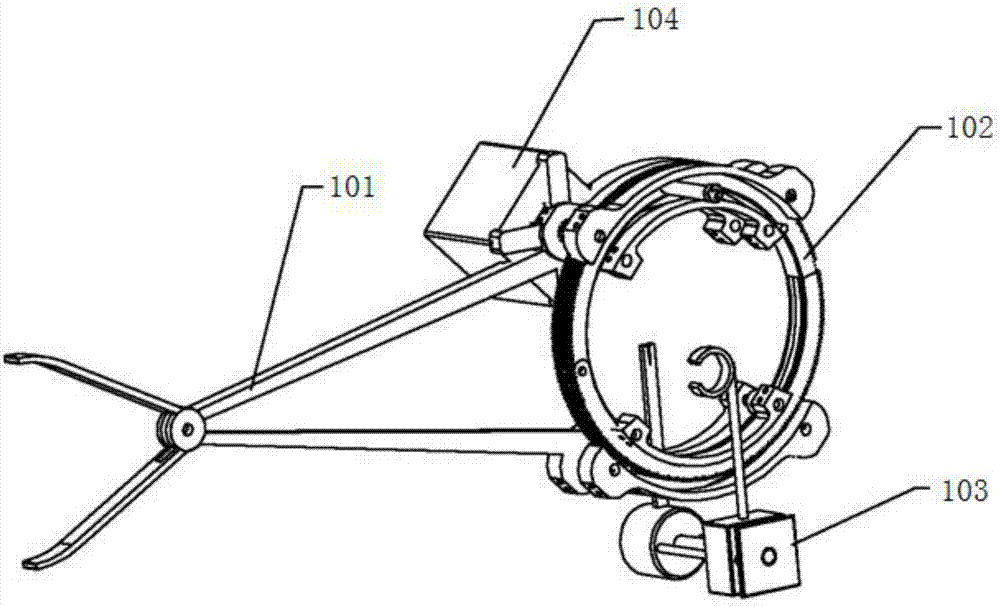

[0022] like figure 1 As shown, the present invention provides a semi-automatic strapping device, which is mainly composed of a gear opening and closing pliers 101 , an openable gear 102 , a linear motor 103 and a servo motor 104 . The linear motor 103 is fixed on the base, the servo motor 104 is fixed on the gear opening and closing pliers 101, and the openable gear is connected on the gear opening and closing pliers 101.

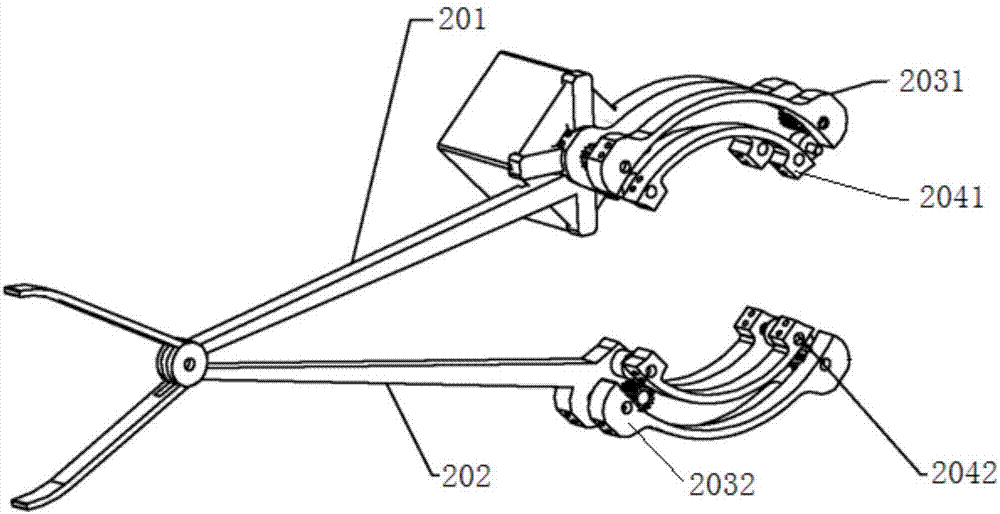

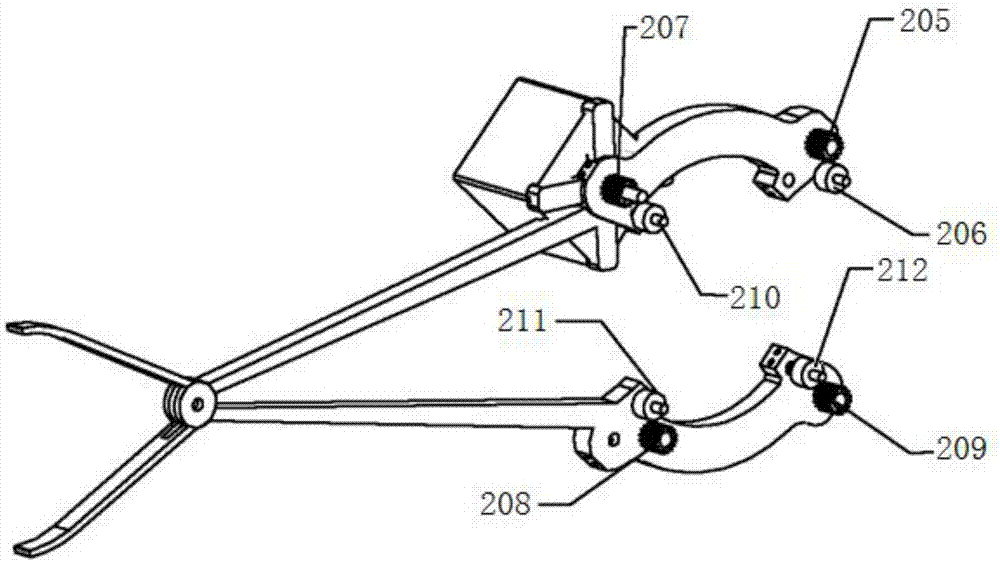

[0023] like figure 2 , image 3 As shown, the gear opening and closing pliers 101 is composed of upper opening pliers 201, lower opening pliers 202, upper clamping plate I2031, upper clamping plate II2041, lower clamping plate I2032, lower clamping plate II2042, driven gear I205, pulley I206 , driving gear 207, driven gear II 208, driven gear III 209, pulley II 210, pulley III211, pulley IV 212. The upper opening pliers 201 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com