Ethylene-propylene insulated rubber-sheathed flexible cable and preparation method thereof

A technology of ethylene-propylene insulation and ethylene-propylene rubber insulation. It is applied in the direction of insulated cables, cable/conductor manufacturing, and insulated conductors. It can solve the problems of poor tensile and crimp resistance, high requirements for cable materials, and poor cable anti-interference performance. Problems, to achieve the effect of increasing cushioning elasticity and extrusion resistance, strong wear resistance, and reducing the impact inside the cable body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

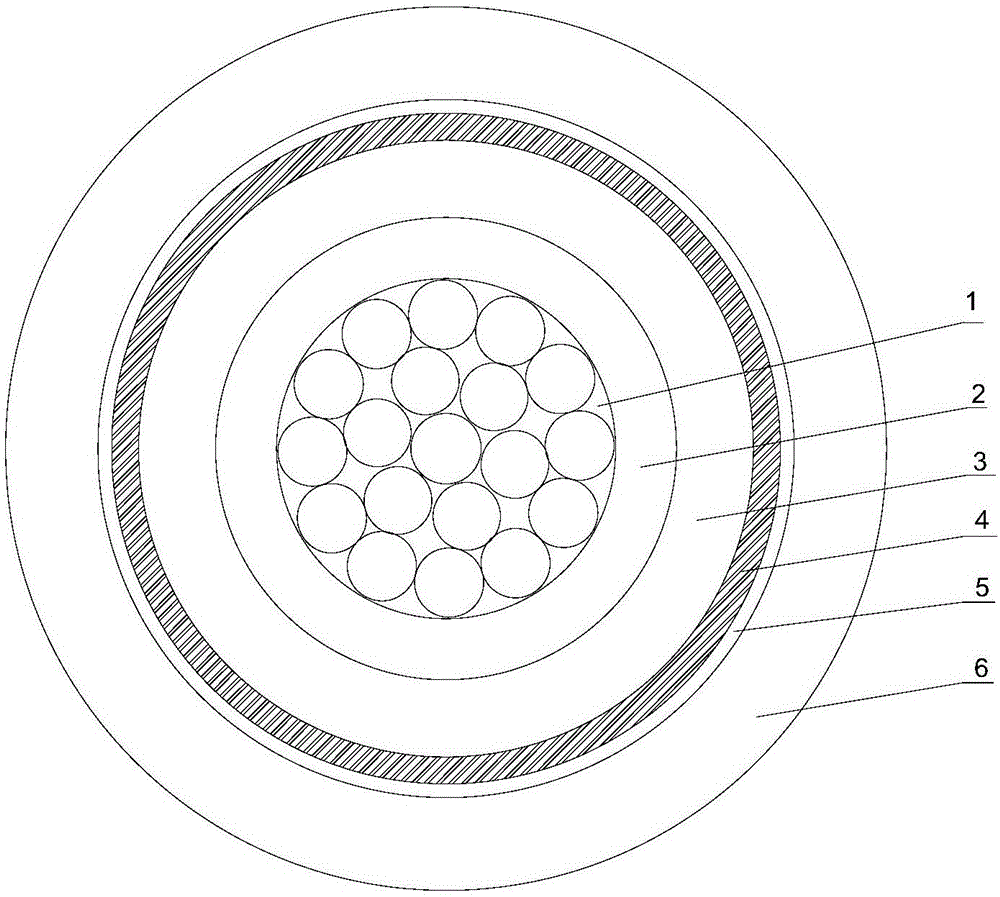

[0029] Such as figure 1 As shown, an ethylene-propylene insulated rubber-sheathed flexible cable includes a central conductor 1, a conductor shielding layer 2, an ethylene-propylene rubber insulating layer 3, an insulating shielding layer 4, a metal shielding layer 5 and an outer sheath layer 6, and the central conductor The outer side of 1 is covered with the conductor shielding layer 2, the ethylene-propylene rubber insulating layer 3, the insulating shielding layer 4, the metal shielding layer 5 and the outer sheath layer 6 in turn, and the central conductor 1 is composed of a plurality of annealed copper conductors to form a core bundle body. The material of the central conductor 1 is tin-plated annealed copper, and the maximum diameter of the monofilament of the central conductor is ≤0.61mm; the material of the conductor shielding layer 2 is semi-conductive nylon tape and semi-conductive rubber; the insulating shielding layer 4 The material is semi-conductive rubber.

...

Embodiment 2

[0041] An ethylene-propylene insulated rubber-sheathed flexible cable. Compared with Example 1, the outer sheath layer 6 is a chlorinated polyethylene sheath rubber, and the chlorinated polyethylene sheath rubber is made of the following raw materials in parts by weight: 100 parts of chlorinated polyethylene rubber, 3 parts of triallyl isocyanate, 8 parts of urea-formaldehyde resin, 50 parts of nano-attapulgite, 5 parts of carbon nanotubes, 55 parts of high wear-resistant carbon black, precipitated white carbon black 5 parts, 1 part of dodecyltrimethoxysilane, 4 parts of dioctyl phthalate, 1 part of microcrystalline paraffin and 3 parts of anti-aging agent RD.

[0042] All the other parameters and preparation process are the same as in Example 1.

Embodiment 3

[0044] An ethylene-propylene insulated rubber-sheathed flexible cable. Compared with Example 1, the outer sheath layer 6 is a chlorinated polyethylene sheath rubber, and the chlorinated polyethylene sheath rubber is made of the following raw materials in parts by weight: 90 parts of chlorinated polyethylene rubber, 4 parts of triallyl isocyanate, 6 parts of urea-formaldehyde resin, 55 parts of nano-attapulgite, 3 parts of carbon nanotubes, 60 parts of high wear-resistant carbon black, precipitated white carbon black 3 parts, 2 parts of dodecyltrimethoxysilane, 3 parts of dioctyl phthalate, 2 parts of microcrystalline paraffin and 2 parts of antioxidant RD.

[0045] All the other parameters and preparation process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com