Intelligent manufacturing technology application training platform

A training platform and intelligent manufacturing technology, applied in the direction of educational appliances, teaching models, instruments, etc., can solve the problems of unstable structure, unable to keep up with automatic continuous production, and affecting the simulation degree of assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

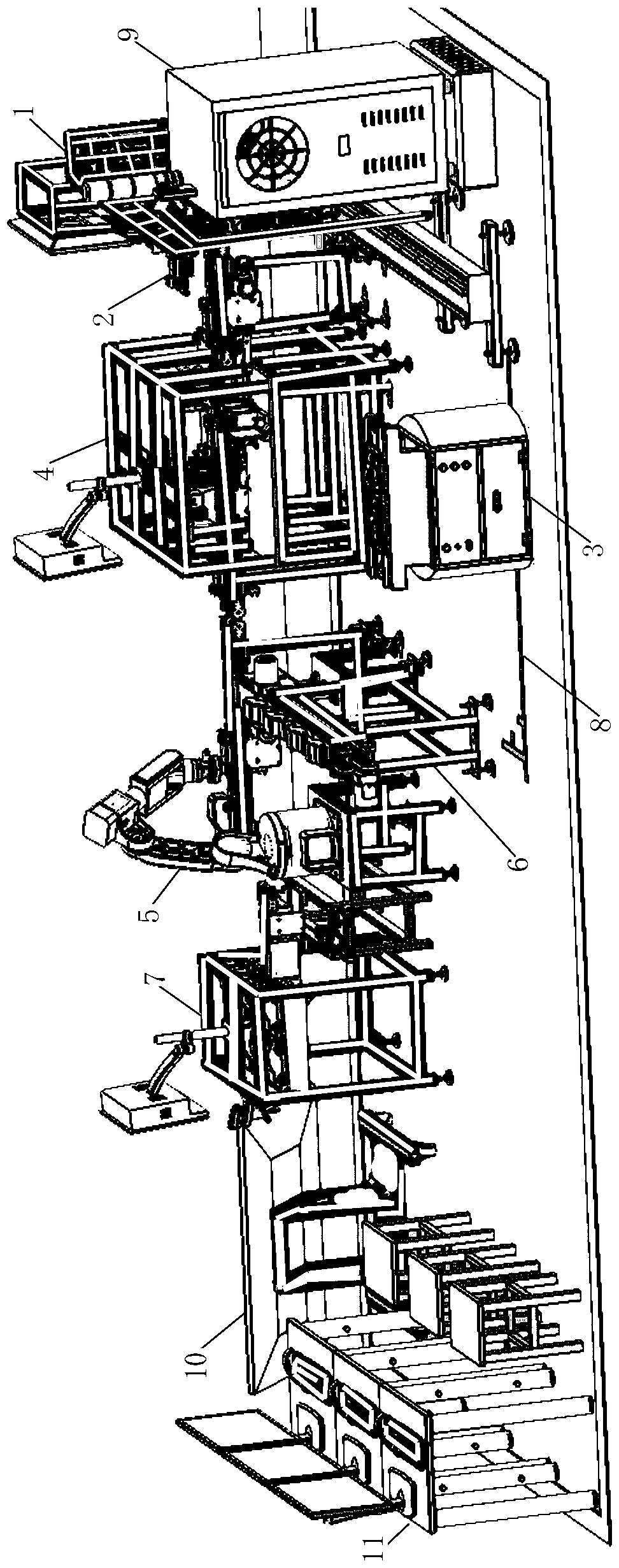

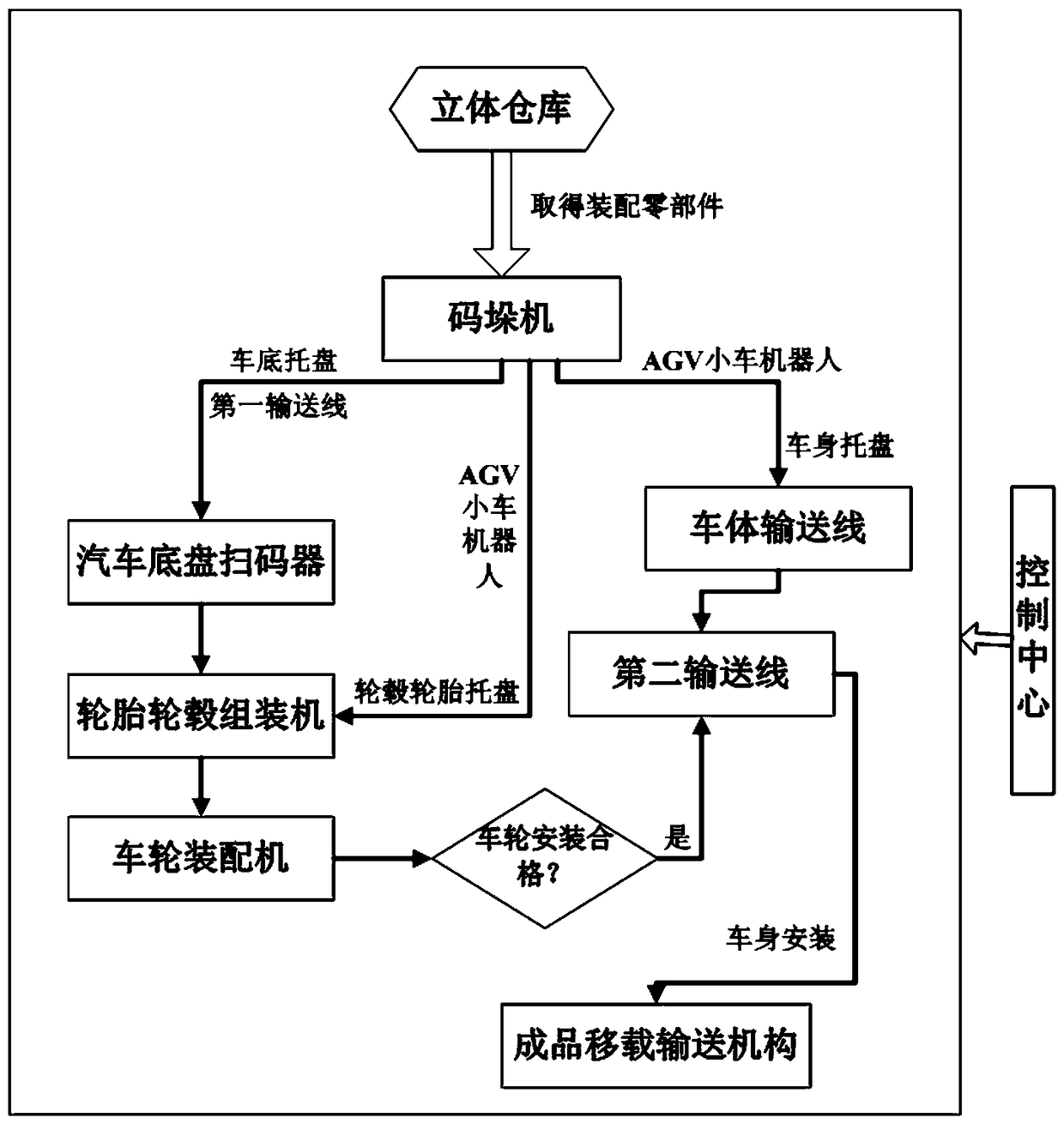

[0092] Refer to attached figure 1 The intelligent manufacturing technology application training platform of the present invention includes a three-dimensional warehouse 1, a palletizer 2, an AGV trolley robot 3, a hub tire and wheel assembly system 4, a vehicle body assembler 5, a vehicle body conveying line 6, and a finished product transfer conveying mechanism 7 , magnetic guide rail 8 and control center 9; the three-dimensional warehouse 1 and the palletizer 2 are adjacently arranged, and a first conveying line is arranged between the palletizer 2 and the hub tire and wheel assembly system 4, and the hub tire and wheel assembly system 4 and A second conveying line is provided between the finished product transfer conveying mechanism 7, and the vehicle body assembler 5 is fixed on the vehicle body assembly platform and then placed beside the second conveying line, and a vehicle body conveying line is also provided at a position parallel to the side of the vehicle body assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com