Wheel tire and wheel assembly system

A technology for assembling systems and tires, applied in toy cars, toys, entertainment, etc., can solve the problems of unstable structure, difficult positioning, and low production efficiency, and achieve the effect of reasonable design, compact structure, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

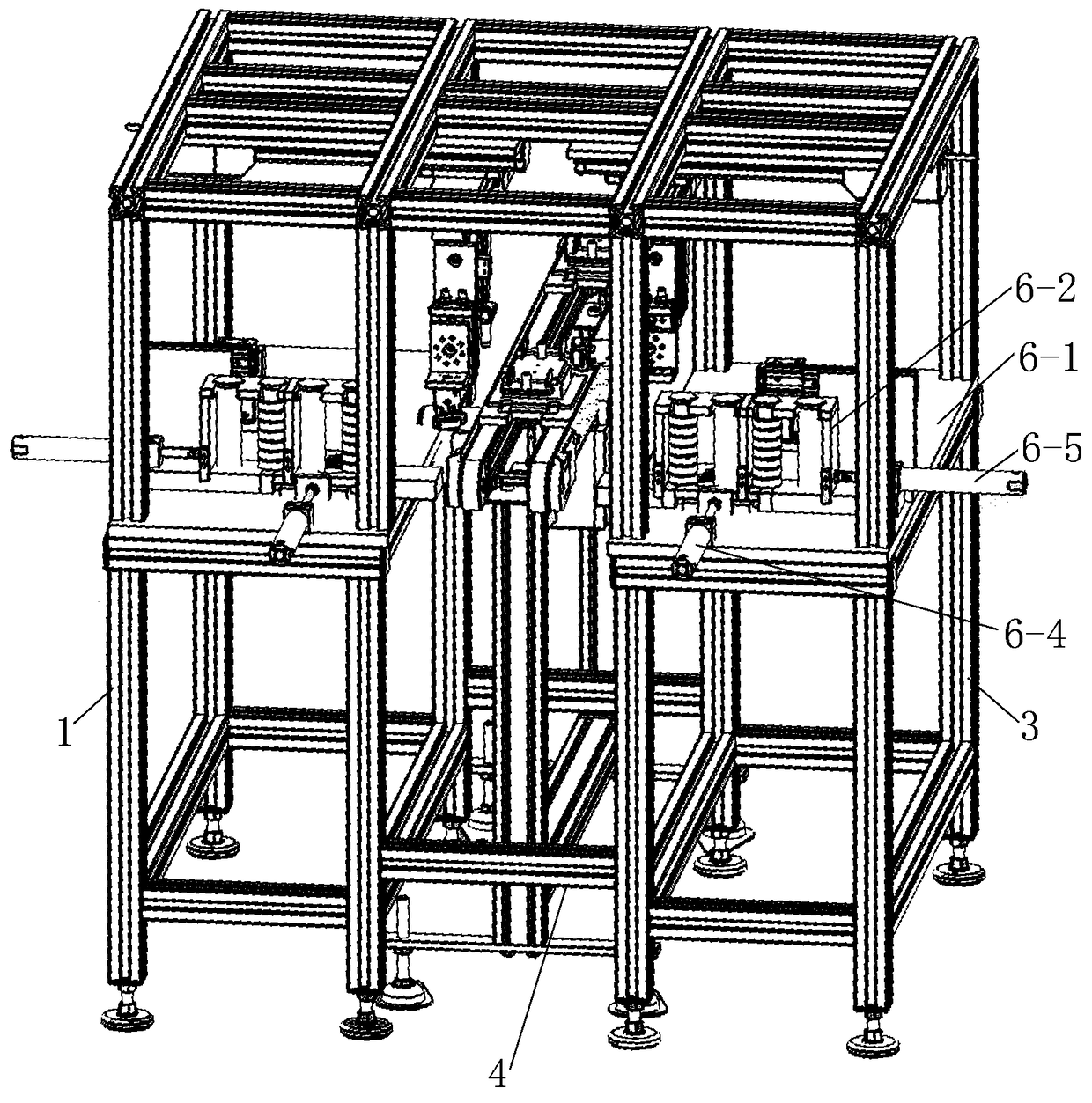

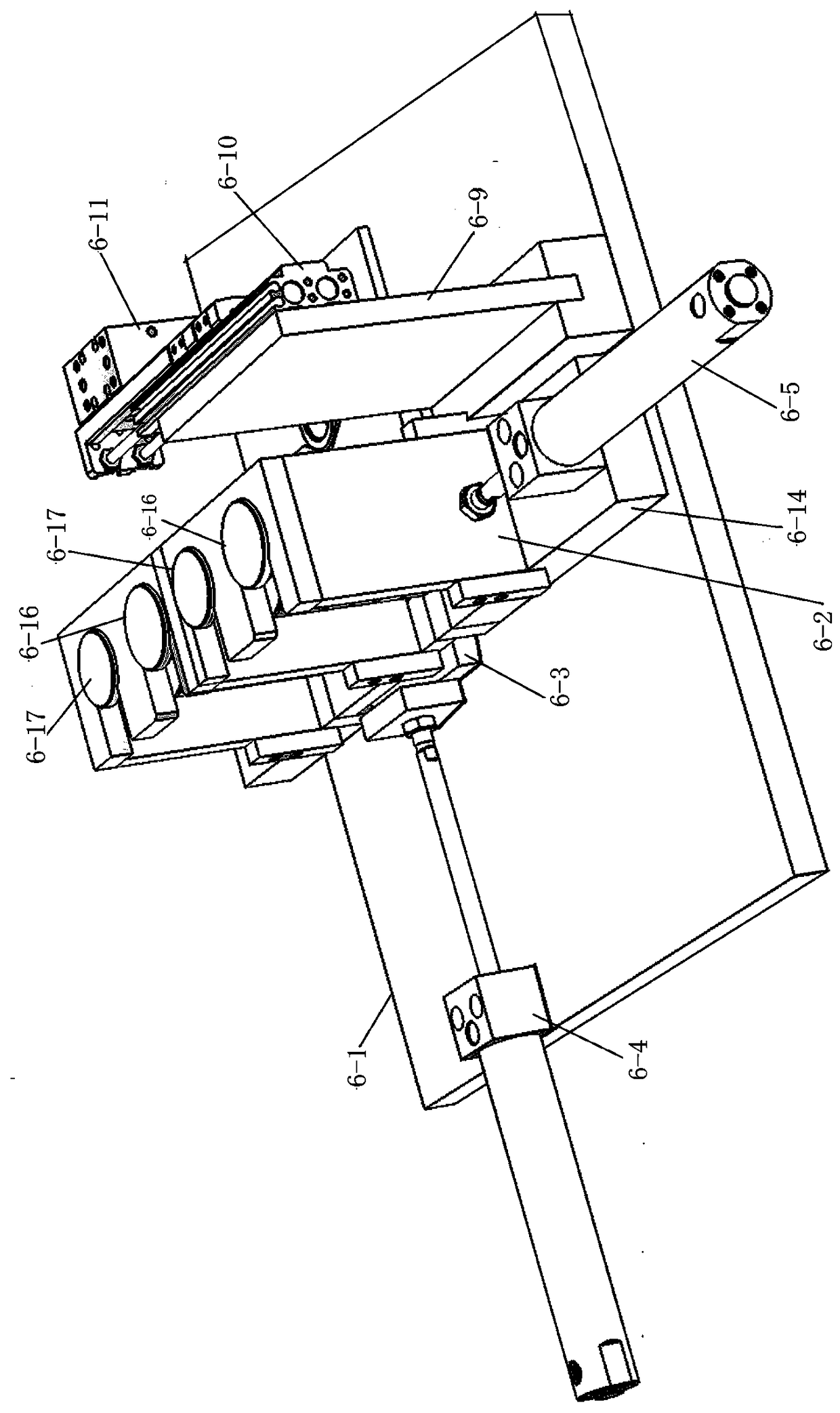

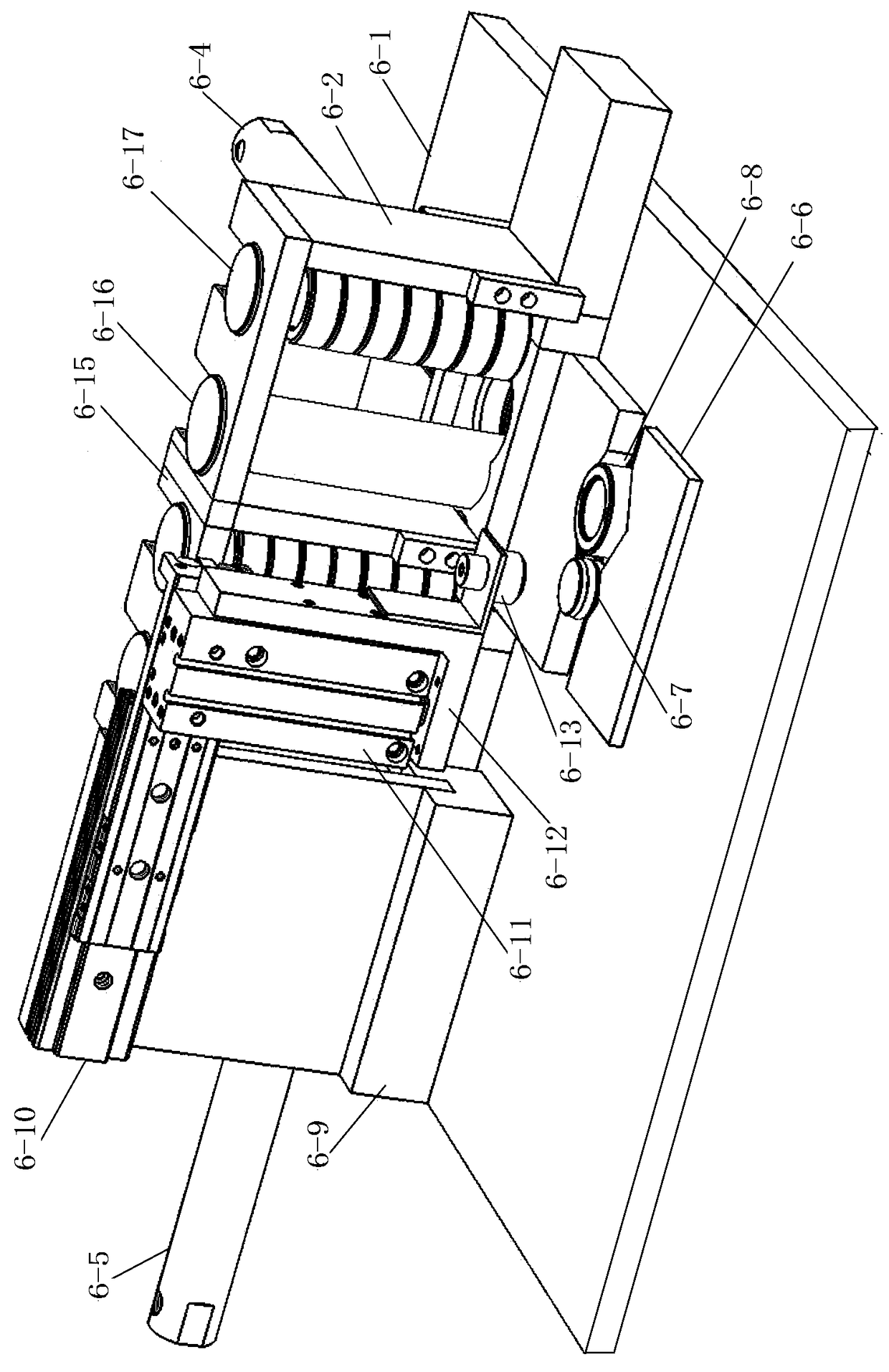

[0031] Refer to attached Figure 1~6 , the wheel hub tire and wheel assembly system of the present invention includes an assembly frame, and the assembly frame is divided into three parts: a left assembly frame 1, a middle assembly frame 2 and a right assembly frame 3, and there are respectively arranged in the middle of the left assembly frame 1 and the right assembly frame 3. The installation platform is symmetrically equipped with tire hub assembly machines on the two installation platforms, and the middle part of the middle assembly frame is provided with a conveyor platform 4, and a conveyor belt conveyor line 5 is installed on the conveyor platform 4, and the conveyor belt conveyor line 5 runs through the entire Assembling stand; Suspender is arranged on the top of left assembling stand 1 and right assembling stand 3, and wheel assembly machine is housed in the middle part of suspension rod, and wheel assembly machine is positioned at the rear portion of tire hub assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com