A Visual Dynamic Evaluation Method of Rolling Bearing Reliability Based on Statistics by Class

A rolling bearing, dynamic evaluation technology, applied in design optimization/simulation, calculation, instrument, etc., can solve the problem of inability to intuitively express equipment degradation state, inability to adaptively adjust running time, inability to realize visual display and real-time tracking and reliability of rolling bearing It can achieve the effect of real-time tracking, dynamic evaluation and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

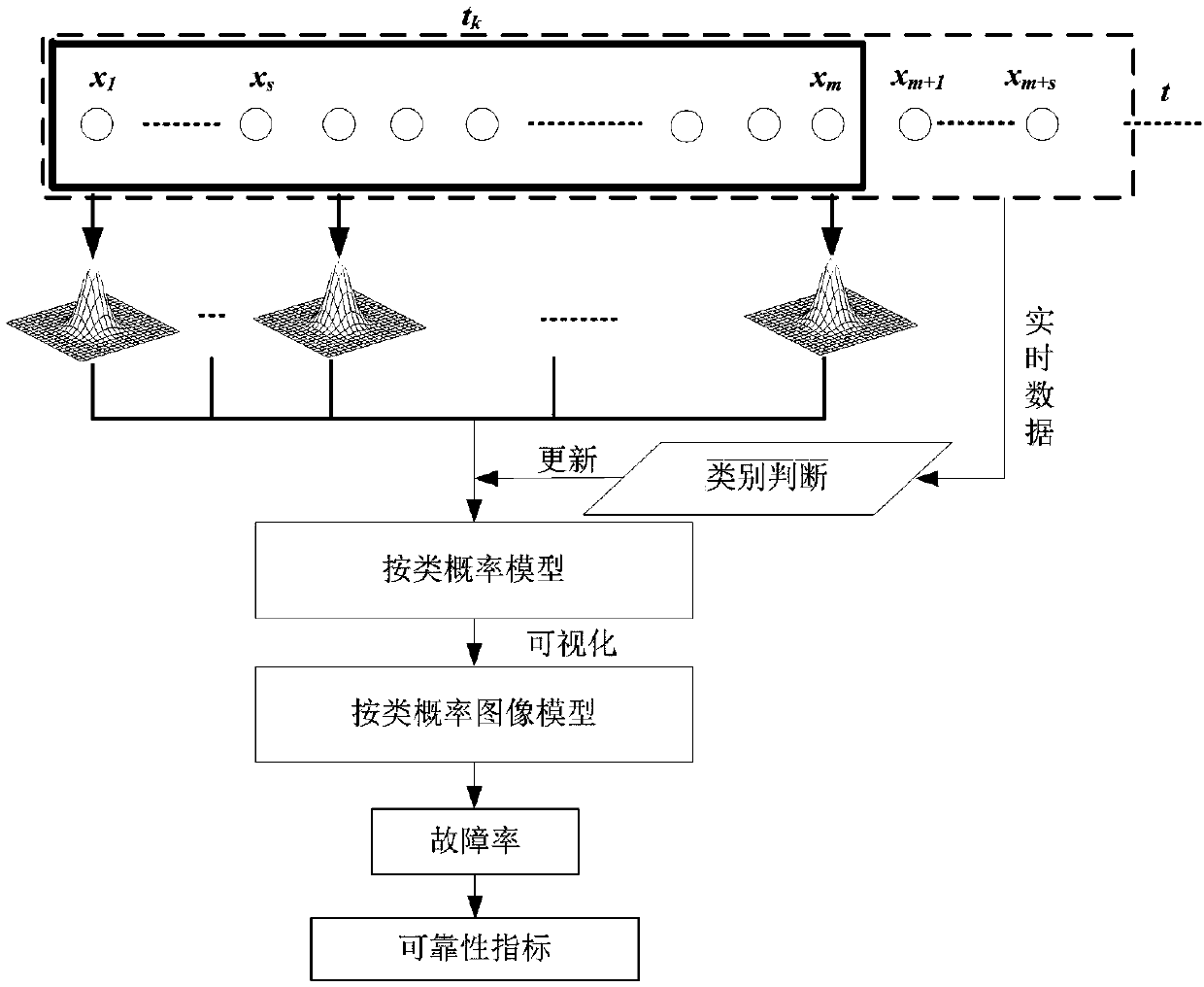

[0034] refer to figure 1 , a visual dynamic evaluation method for rolling bearing reliability based on class statistics, including the following steps:

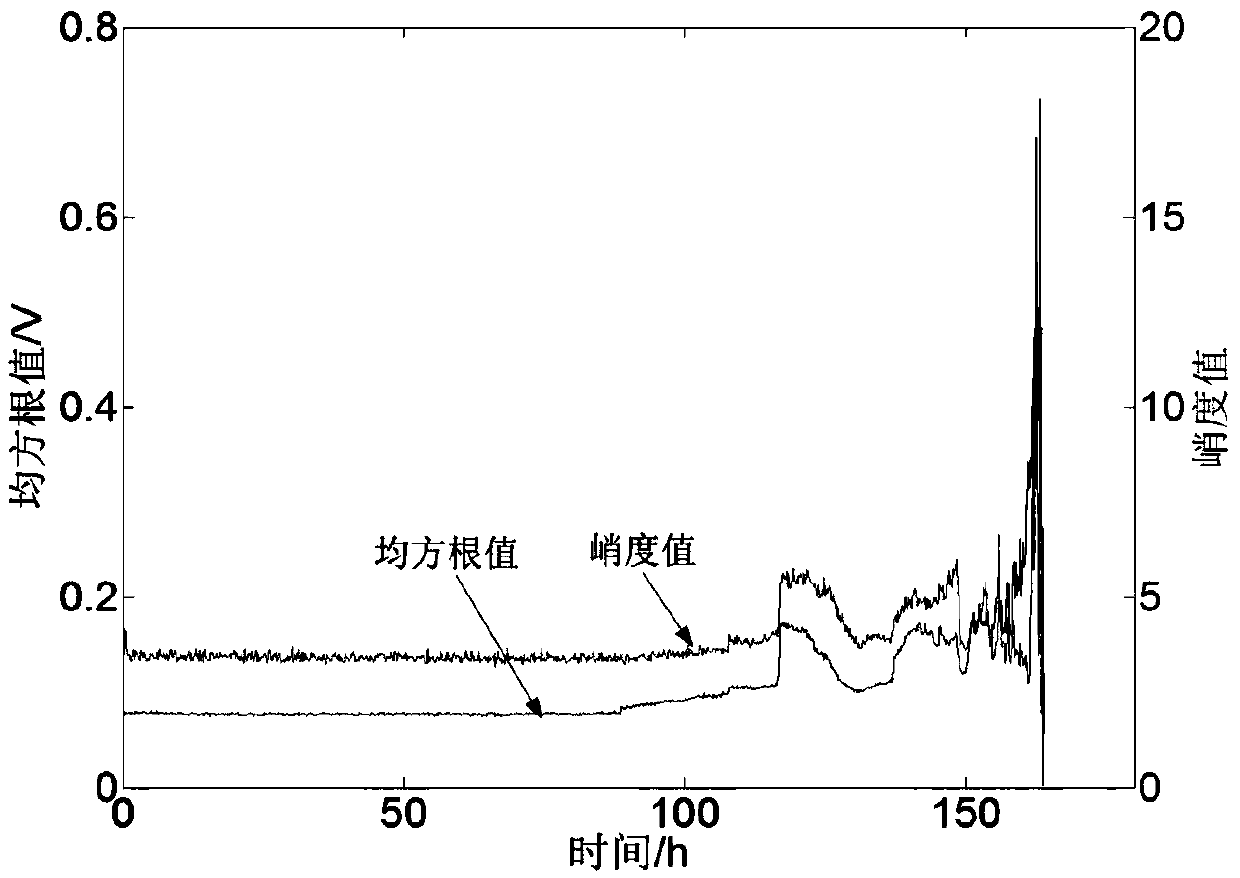

[0035] The first step is to obtain the vibration data of the rolling bearing, and extract the two performance characteristic indexes of root mean square and kurtosis. Normalization processing: X i with are respectively the performance index data sequence of the i-th dimension and the preprocessed performance index data sequence, and the preprocessing formula is:

[0036]

[0037] Such as figure 2 as shown, figure 2 It is a graph showing the change of two performance indexes of rolling bearings with time;

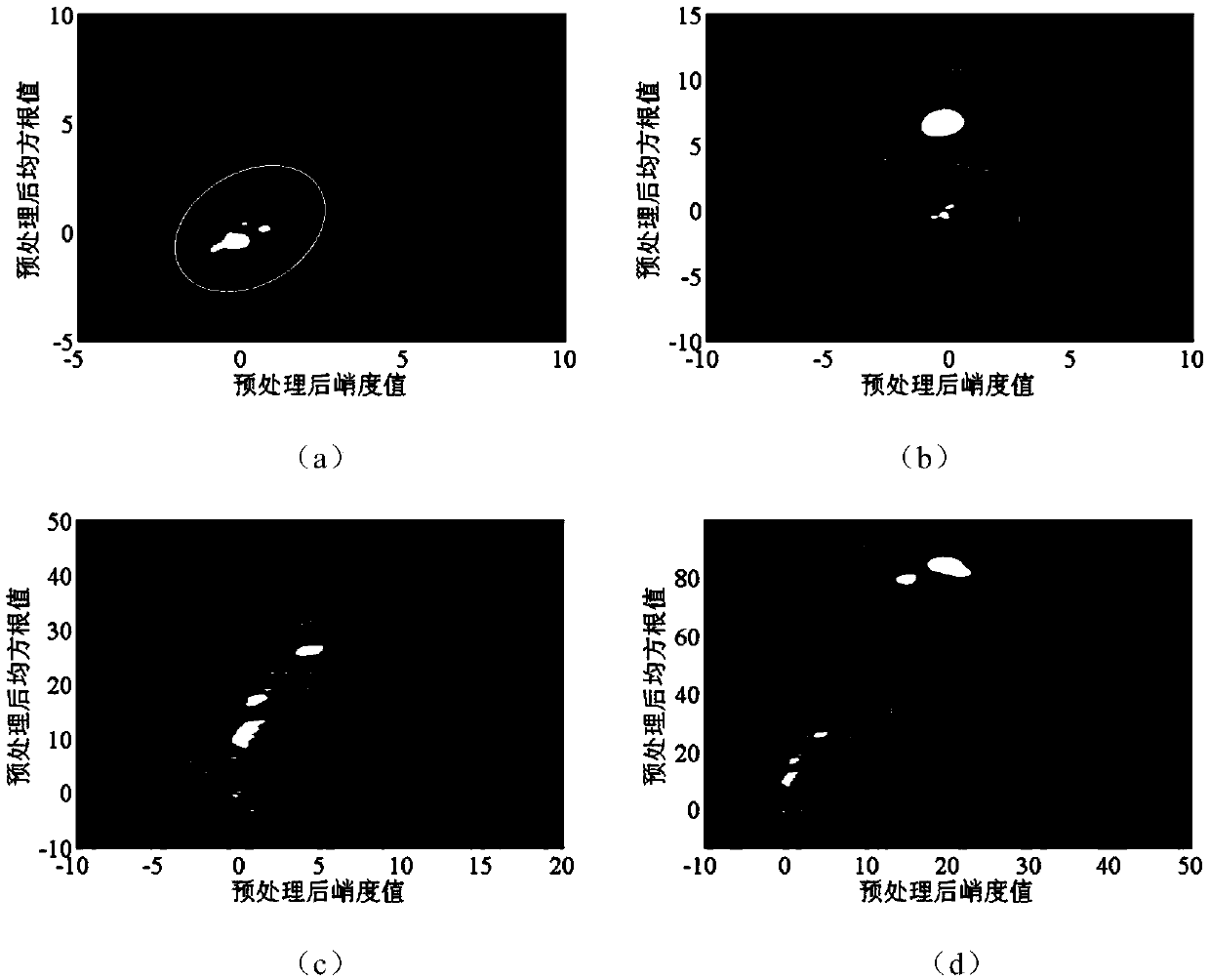

[0038] The second step is to obtain a certain amount of two-dimensional performance index data under normal conditions as a statistical sample Call this statistical sample the normal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com