Fuzzy self-tuning PID control method used for denitration control system

A control system and control method technology, applied in the field of control, can solve the problems of large delay, nonlinearity, and poor control effect of the denitrification system, and achieve the effect of being intelligent and reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

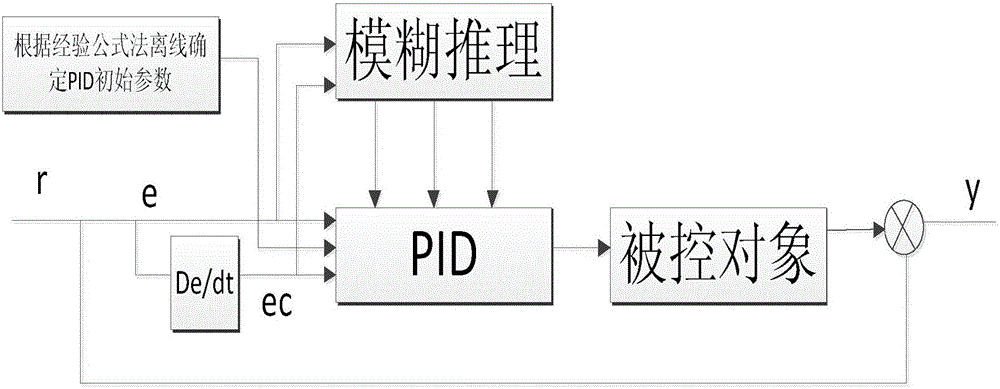

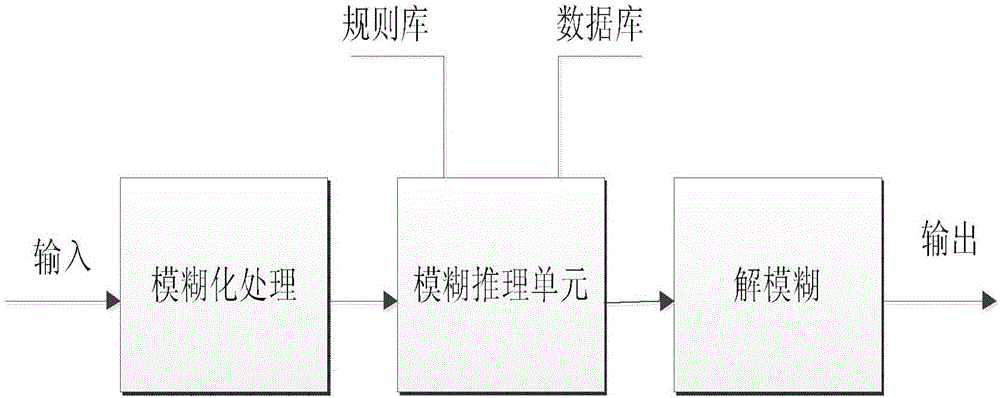

[0070] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The fuzzy self-tuning PID control method for the denitrification control system of the present invention comprises the following steps:

[0071] 1. Determine the fuzzy rule table of Kp, Ki, Kd;

[0072] Find out the relationship between error (e) and error rate of change (ec) and Kp, Ki, Kd,

[0073] The determination rule of proportional coefficient Kp:

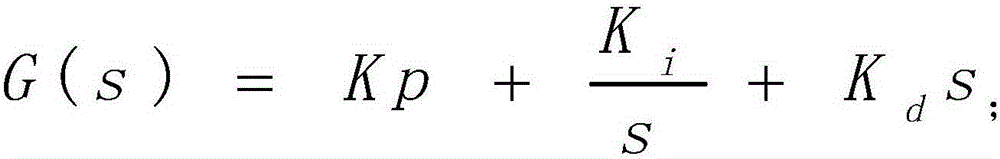

[0074] When the controlled object remains unchanged, use the PID parameters to adjust the object to the best control performance. At this time, according to the transfer function of the PID, Kp can be obtained as a proportional coefficient, Ki is an integral coefficient, and Kd is a differential coefficient. In the formula, 1 / s is the integral link, and s is the differential link;

[0075] The transfer function of PID control is:

[0076]

[0077] In the initial stage of the control process, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com