Determination method of high-pressure water injection and radial gas permeability of gas-containing raw coal

A measurement method and permeability technology, applied in the field of coal mine disaster prevention and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with specific embodiments.

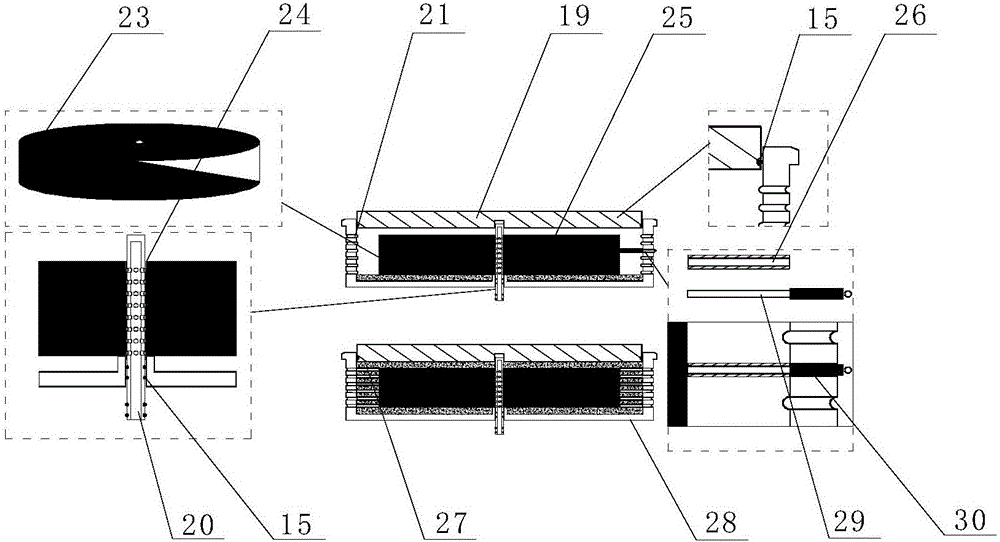

[0034] Such as image 3 Shown, the preparation method of raw coal sample of the present invention specifically comprises the following steps:

[0035] A. On-site along the coal mining face, select areas with clear bedding and good integrity for groove sampling. The cubes with a size of 400×400×400mm are sealed and sent to the laboratory. 4 types of coal samples with low porosity are used as experimental coal samples;

[0036] B. The cutting machine is prepared into a cylindrical sample 23 of Φ300×h50mm. The cylindrical surface is divided into two types of samples along the bedding and vertical bedding directions, and the surface is polished. A Φ10mm water injection hole is drilled in the center of the cylinder and installed. The water injection flower tube 20, the two ends of the water injection flower tube 20 and the columnar body sample 23 are sealed by silica gel 24,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com