A portable cleaning device for porous tube sheets

A technology for cleaning equipment and porous tube sheets, which is applied to the cleaning of rotating equipment, lighting and heating equipment, and flushing. It can solve the problems of long cleaning time, difficult cleaning of tube sheets, and difficult cleaning of tube holes, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

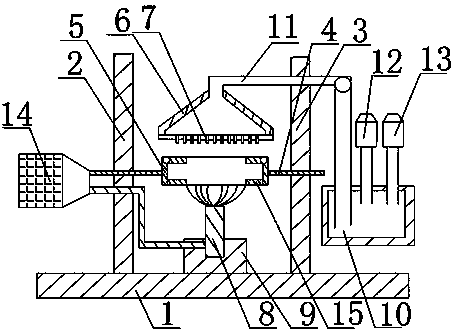

[0021] Such as figure 1 As shown, a portable cleaning device for a porous tube sheet of the present invention includes a base 1, a fixed plate A2 and a fixed plate B3 are fixed above the base 1, and a rotating shaft 4 is connected between the fixed plate A2 and the fixed plate B3, and the rotating shaft 4 A hollow shelf 5 with a fixed tube sheet is installed on it, and a conical nozzle 6 is installed above the shelf 5. A plurality of nozzles 7 are arranged at the lower end of the nozzle 6. The nozzle 6 is connected with a water storage device. A rotating brush 8 is installed, and the lower end of the rotating brush 8 is connected with a telescopic rod 9, and the telescopic rod 9 is fixed on the base 1. Both the rotating shaft 4 and the rotating brush 8 are connected to the motor 14, and the motor 14 is located on the side of the fixed plate A2 away from the fixed plate B3. The water storage device includes a reservoir 10 connected to the nozzle 6, the reservoir 10 is located ...

Embodiment 2

[0024] Based on Embodiment 1, a cold water bottle 12 and a thermos bottle 13 are connected above the reservoir 10, and the thermos bottle 13 is covered with an insulation layer. The water for cleaning the tube sheet can be selected according to the season and the appropriate water temperature, and can also be selected according to the stains on the tube sheet, and a detergent for cleaning oil stains or a special cleaning agent for the tube sheet can also be added to the reservoir.

Embodiment 3

[0026] Based on the above embodiment, the rack 5 is provided with a plurality of baffles 15 for fixing the tube sheet, and the baffles 15 above the rack 5 are connected to the rack 5 through hinges. Baffles are set around the frame of the storage rack to fix the tube sheet. Since the middle of the tube sheet is hollow, a baffle is required to block the tube sheet when the tube sheet is fixed on the storage rack; the baffle located above the storage rack and the storage rack The movable link is to facilitate the prevention of the tube sheet. When the tube sheet needs to be placed, just open the baffle above the shelf; the surface where the baffle contacts the tube sheet should also be provided with a rubber layer for anti-slip and anti-wear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com