Automatic reversing water pump

An automatic reversing and water pump technology, applied in pump control, machine/engine, liquid variable capacity machinery, etc., can solve the problems of inability to provide electrical system drive power, complex water pump system, etc., and achieve light weight, simple implementation, and high performance. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

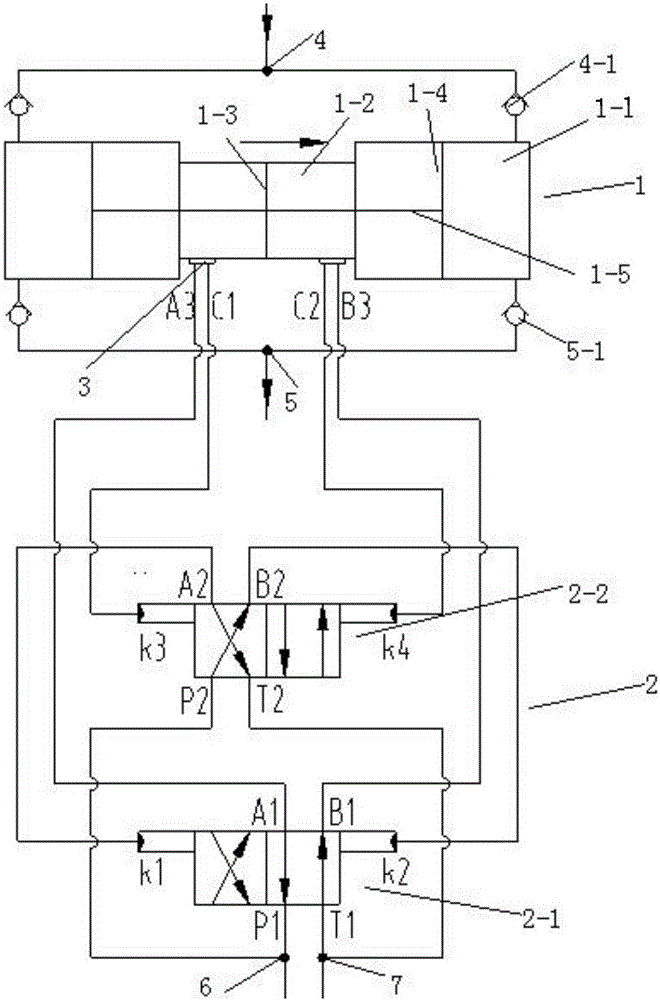

[0023] Please refer to the attached figure 1 , this embodiment includes a water pump body 1 and a hydraulic drive system 2 , the hydraulic drive system 2 communicates with the water pump body 1 , and a signal valve 3 is provided between the hydraulic drive system 2 and the water pump body 1 .

[0024] In this embodiment, the hydraulic drive system 2 includes hydraulically controlled reversing valve one 2-1 and hydraulically controlled reversing valve two 2-2, hydraulically controlled reversing valve one 2-1 and hydraulically controlled reversing valve two 2- 2 are equipped with a working oil port, a driving oil port, an oil inlet and an oil return port, and the working oil ports of the hydraulic control reversing valve 2-1 include A1 port and B1 port, and the hydraulic control reversing valve The working oil port of two 2-2 includes A2 port and B2 port, the driving oil port of said hydraulic control reversing valve one 2-1 includes k1 port and k2 port, and the driving oil port...

Embodiment 2

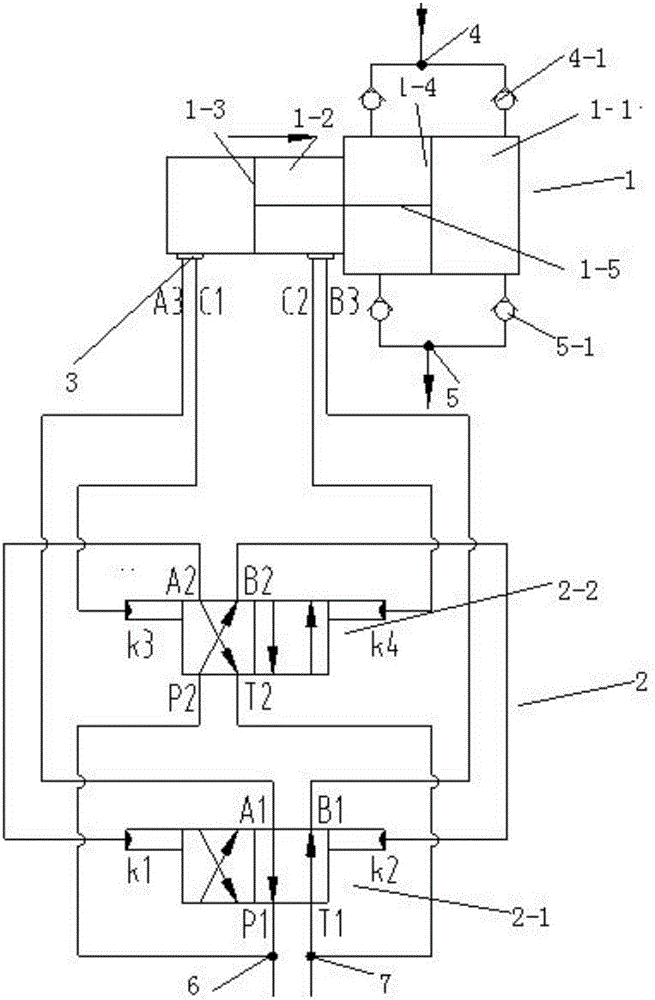

[0041] Please refer to the attached figure 2 , The difference between this embodiment and Embodiment 1 is that the number of the water cylinder 1-2 is one, and the water cylinder 1-2 is arranged on the right side of the oil cylinder 1-1. The rest are basically the same as in Example 1.

[0042] Light weight; the output flow can be adjusted as required; the power direction is consistent with the action direction of the water pump, with low power consumption and high efficiency; strong anti-pollution ability, no unbalanced load of the water pump piston, and increased life; at the end of the stroke of the cylinder 1-1, the hydraulic signal The acquisition methods are diversified and the implementation is simple.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the number of the water tank 1-2 is one, and the water tank 1-2 is arranged on the left side of the oil tank 1-1. The rest are basically the same as in Example 1.

[0045] Light weight; the output flow can be adjusted as required; the power direction is consistent with the action direction of the water pump, with low power consumption and high efficiency; strong anti-pollution ability, no unbalanced load of the water pump piston, and increased life; at the end of the stroke of the cylinder 1-1, the hydraulic signal The acquisition methods are diversified and the implementation is simple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com