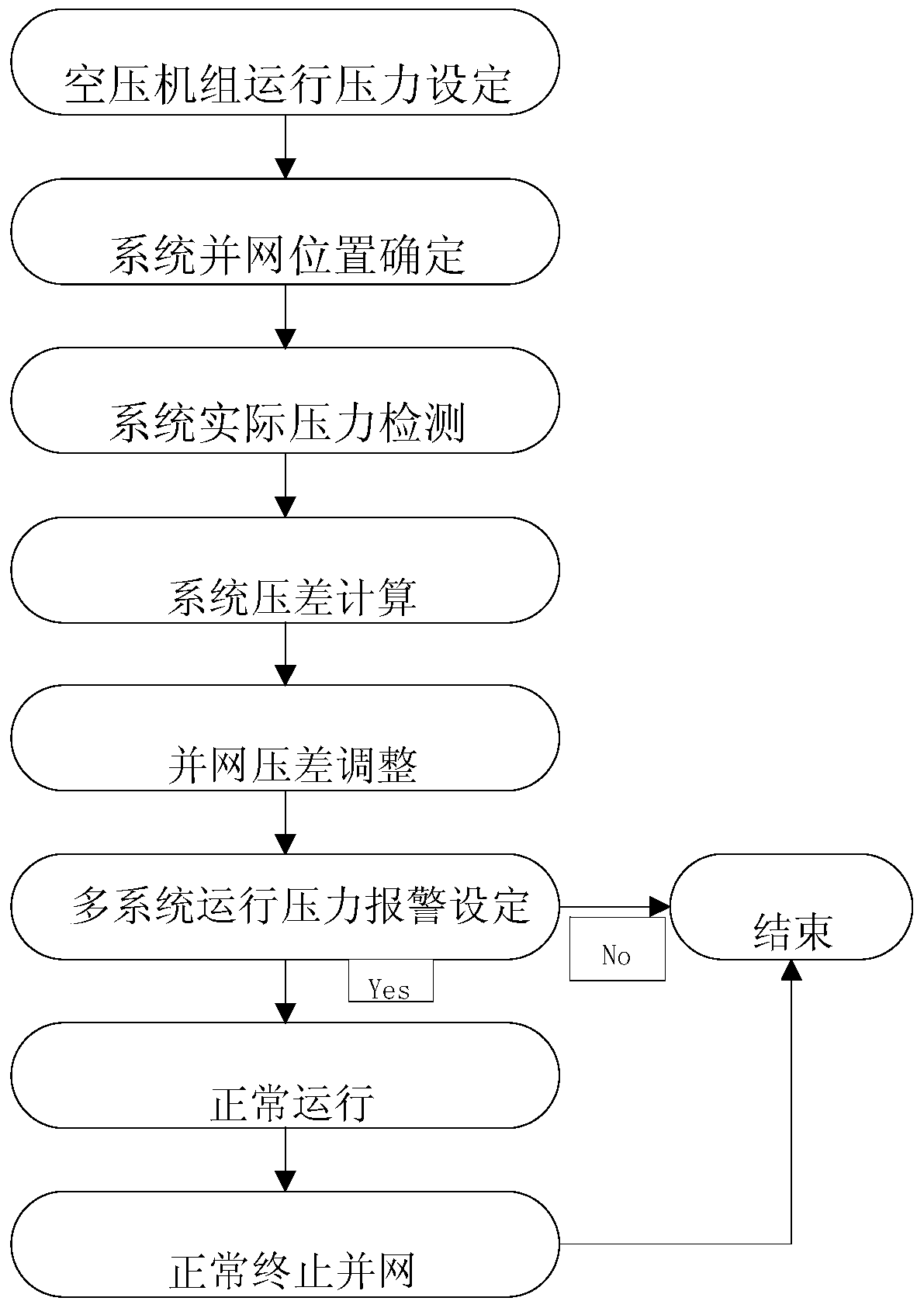

A pressure difference compensation control method for compressed air grid-connected operation of multi-system air compressor stations

A technology of compressed air and compensation control, which is applied in the direction of pump control, liquid variable capacity machinery, pumps, etc. It can solve the problems of frequent start and stop of motors, inability to continuously adjust, and inability to realize soft start of multiple air compressors, so as to prevent The effect of fault expansion and fast opening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

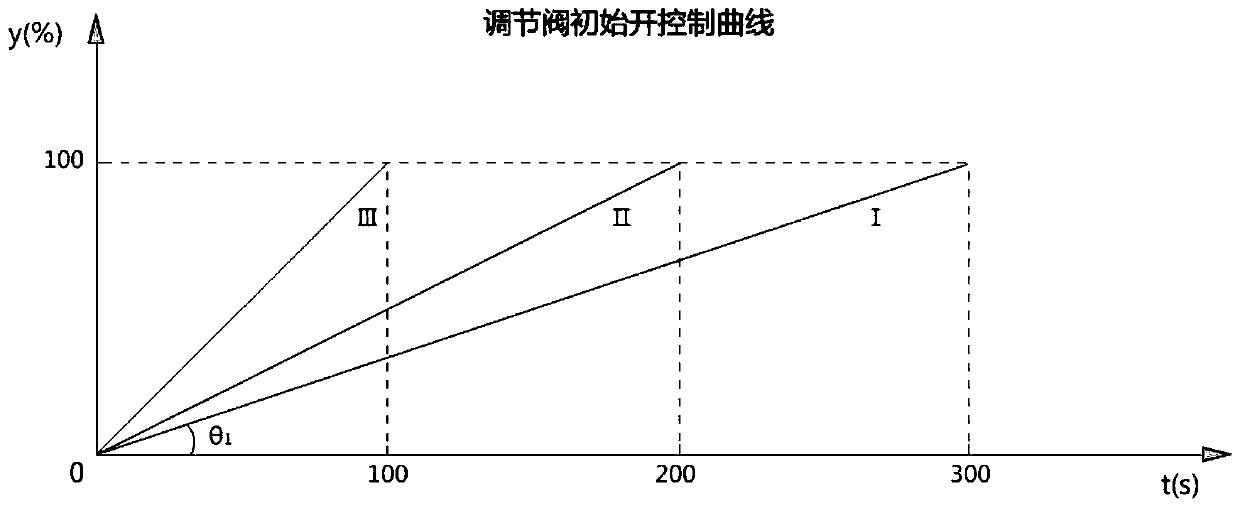

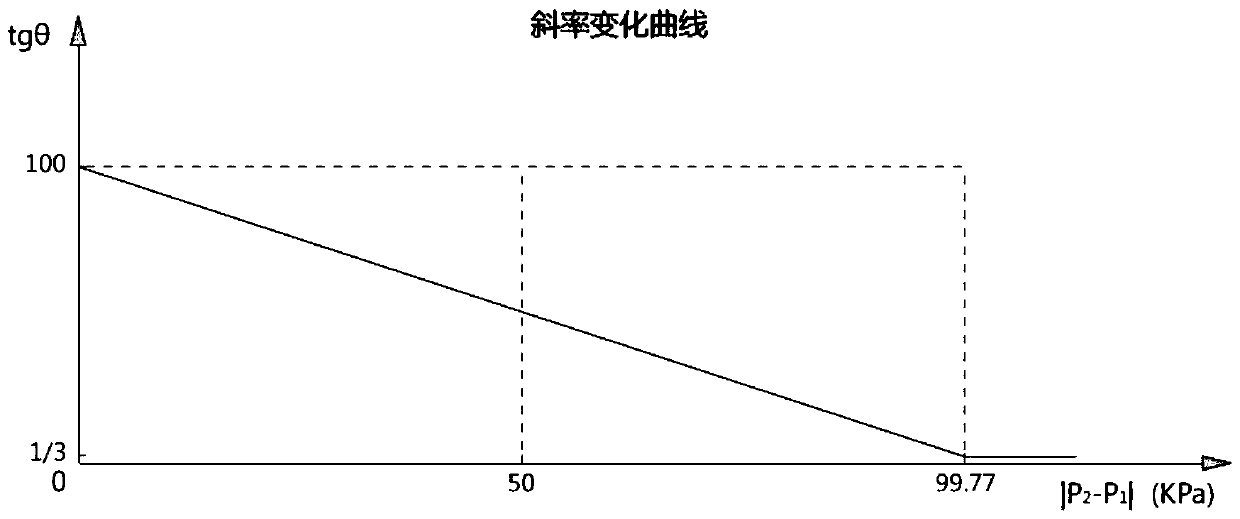

[0125] According to the actual situation of the 1#2# air compressor station system in a steel plant, the actual working pressure difference between the two systems is 100KPa, and the one-way full stroke setting of the regulating valve is 300S for analysis.

[0126] 1. The initial opening control of FCV101 is as follows figure 2 , as shown in 3.

[0127] 2. When FCV101 initially moves from fully closed to open, the valve opening is given according to the curve I (or II, III) according to the actual system pressure difference |p1-p2|. The larger the pressure difference, the smaller the slope of the curve and the longer the valve action time. Conversely, the smaller the pressure difference, the larger the slope of the curve and the shorter the valve action time. When the pressure difference is greater than the set 100KPa, it is always controlled according to curve Ⅰ.

[0128]

[0129] p1 indicates the detection pressure of PT101,

[0130] p2 indicates the detection pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com