Method for using polyolefin plastic to prepare micromolecule alkene

A polyolefin and small molecule technology, which is applied in the thermal cracking/catalytic cracking-microwave cracking two-step method to recover polyolefin plastics and produce small molecule olefins, can solve the problems of limiting the scope of application of cracking raw materials, and achieve higher cracking temperature, The effect of improving heating efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

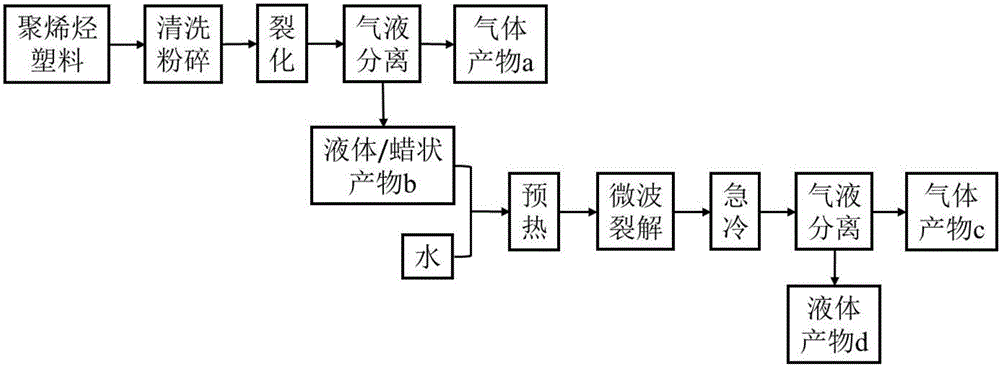

[0059] In this embodiment, LDPE is used as a raw material to prepare small molecular olefins, figure 1 It is a flow chart of the method for preparing small molecular olefins with polyolefin plastics, and the specific steps are as follows:

[0060] (1) Cracking:

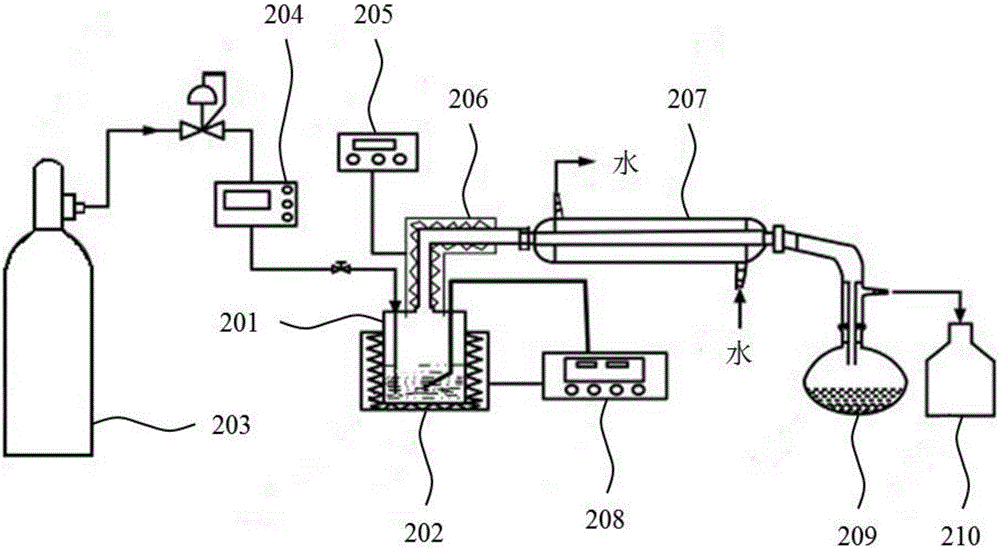

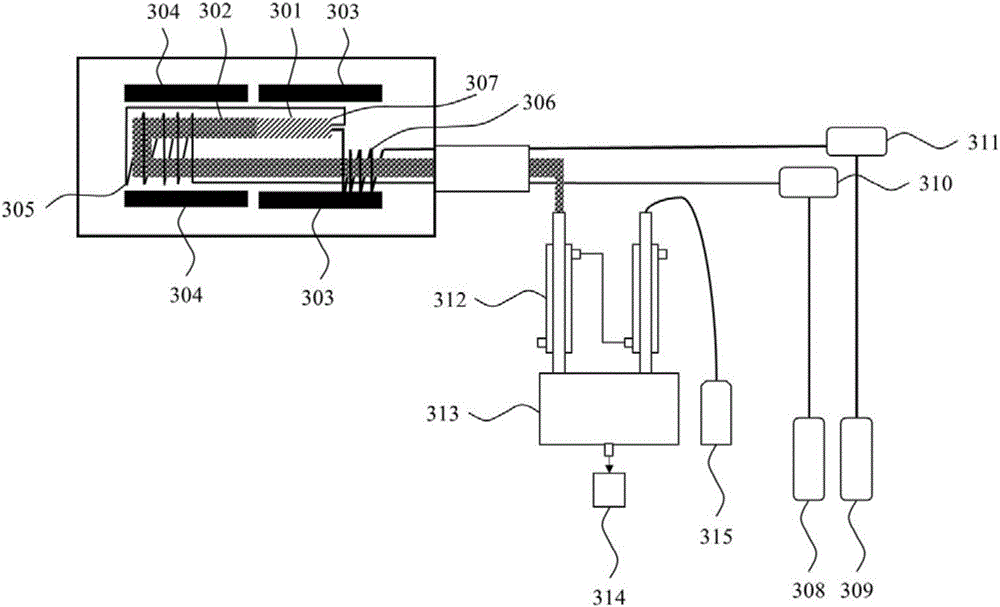

[0061] like figure 2 As shown, before the cracking reaction, a nitrogen purge device 203 is used to purge the semi-continuous mild cracking device to remove the air in the device. First, use the mass flow meter 204 to control the nitrogen flow rate to 50ml / min, and purge for 20 minutes; then set the nitrogen flow rate to 20ml / min, and use nitrogen purge throughout the cracking reaction. The LDPE cleaned and pulverized particles are transported into the reactor 201, and the temperature control device 208 is used to control the power of the heating device 202, so that the temperature rise rate of the reactor 201 is 5°C / min, and the reactor 201 is monitored in real time through the temperature measuring device 205 ac...

Embodiment 2

[0069] In this example, LDPE is used as raw material to prepare small molecular olefins. The specific steps differ from Example 1 in that the mass ratio of water to liquid product b is 0.5:1, the cracking temperature is 1100°C, and the mixture of liquid product b and water The residence time of the feedstock in the cracking zone 302 is 0.005s.

[0070] The results of this embodiment are shown in Table 2-5. As can be seen from Table 3, since the cracking temperature of this embodiment is higher than that of Example 1, the molar content of ethylene and propylene in the gas product c is higher than that of Example 1.

[0071]It can be seen from Table 4 that the total mass yield of the gas product c in this embodiment is 75%, and the mass yield of ethylene and propylene is 52.32%, which is lower than that of Example 1. This is because compared with Example 1, the residence time of the mixture of liquid product b and water in the cracking zone 302 is shorter and the proportion of ...

Embodiment 3

[0073] In this example, LDPE is used as a raw material to prepare small molecular olefins. The difference between the specific steps and Example 1 is that the cracking temperature is 700°C.

[0074] The results of this embodiment are shown in Table 2-5. As can be seen from Table 4, the total mass yield of gas product c of the present embodiment is only 52.02%, wherein the mass yield of ethylene and propylene is 25.33%, which is significantly lower than that of Example 1, indicating that when the microwave cracking temperature is too low, the cracking Insufficient response.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com