A kind of phosphorus-containing flame-retardant epoxy resin modified by epoxy silicone oil and preparation method thereof

A technology of epoxy silicone oil and epoxy resin, which is applied in the field of preparation of epoxy silicone oil hydrophobically modified phosphorus-containing flame retardant epoxy resin, can solve the problem of accelerated aging of epoxy resin, electrical breakdown of epoxy resin parts, and inapplicability and other problems, to achieve the effect of excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

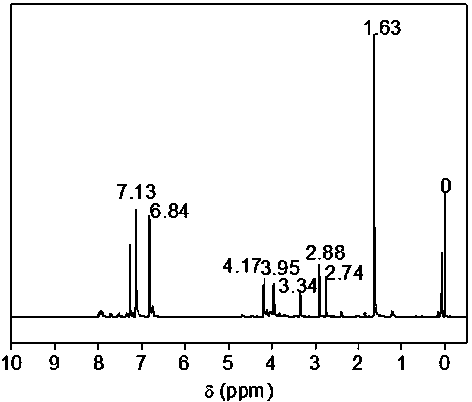

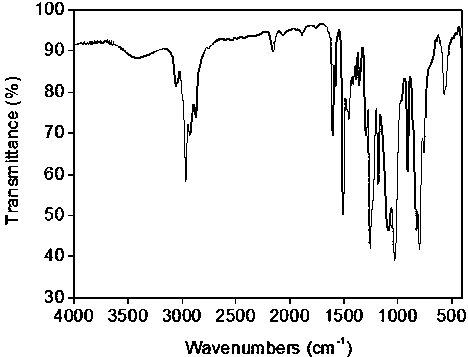

[0029] 1) Add 5 g of epoxy silicone oil, 100 g of DOPO-type phosphorus-containing flame-retardant epoxy resin, 2 g of KH550 and 0.05 g of DBTL into a single-necked Erlenmeyer flask in turn, and react under vacuum at 80 °C for 2 h to obtain light yellow Uncured epoxy silicone oil modified phosphorus-containing flame-retardant epoxy resin (ESO-m-DE);

[0030] 2) Add 100 g of the obtained uncured epoxy silicone oil-modified phosphorus-containing flame-retardant epoxy resin, 50 g of phthalic anhydride and 0.4 g of N,N-dimethylbenzylamine into a polytetrafluoroethylene beaker , after heating and stirring at 40 ℃, pour it into the preheated mold, remove air bubbles in the oven, heat and cure at 100 ℃ for 3 hours, and then heat and cure at 130 ℃ for 10 hours. Cooling, demoulding and sampling, the finished product is obtained.

Embodiment 2

[0032] 1) Add 10 g of epoxy silicone oil, 120 g of DOPO-type phosphorus-containing flame-retardant epoxy resin, 3 g of KH550 and 0.08 g of DBTL into a single-necked Erlenmeyer flask in turn, and react under vacuum at 100 °C for 1 h to obtain light yellow Uncured epoxy silicone oil modified phosphorus-containing flame-retardant epoxy resin (ESO-m-DE);

[0033]2) Add 120 g of the obtained uncured epoxy silicone oil-modified phosphorus-containing flame-retardant epoxy resin, 70 g of methyltetrahydrophthalic anhydride and 0.6 g of N-benzylpyrazinium hexafluoroantimonate Put it into a polytetrafluoroethylene beaker, heat and stir at 60 °C and mix evenly, pour it into a preheated mold, remove air bubbles in an oven, heat and cure at 120 °C for 2 hours, and then heat and cure at 150 °C for 8 hours. After curing, the cured product is cooled with the furnace, demolded and sampled to obtain the finished product.

Embodiment 3

[0035] 1) Add 20 g of epoxy silicone oil, 140 g of DOPO-type phosphorus-containing flame-retardant epoxy resin, 4 g of KH550 and 0.1 g of DBTL into a single-necked Erlenmeyer flask in turn, and react under vacuum at 120 °C for 0.5 h to obtain light yellow Uncured epoxy silicone oil modified phosphorus-containing flame-retardant epoxy resin (ESO-m-DE);

[0036] 2) Add 140 g of the obtained uncured epoxy silicone oil-modified phosphorus-containing flame-retardant epoxy resin, 90 g of hexahydrophthalic anhydride and 0.8 g of N,N-dimethylbenzylamine into a polytetrafluoroethylene beaker, 80 After heating and stirring at ℃ and mixing evenly, pour it into a preheated mold, remove air bubbles in an oven, and then heat-preserve and cure at 140°C for 1 hour, and then heat-preserve and cure at 170°C for 6 hours. After curing, the cured product is cooled with the furnace. Demoulding and sampling, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com