Preparation method of energetic material with controllable interface infiltration performance

A performance and interface technology, applied in the direction of aromatic nitration composition, nitration acyclic/alicyclic/heterocyclic amine explosive composition, nitroalkane composition, etc., can solve the problem of uncontrollable surface and interface wetting properties, and achieve Good complete wetting and coating, good controllability of wetting performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

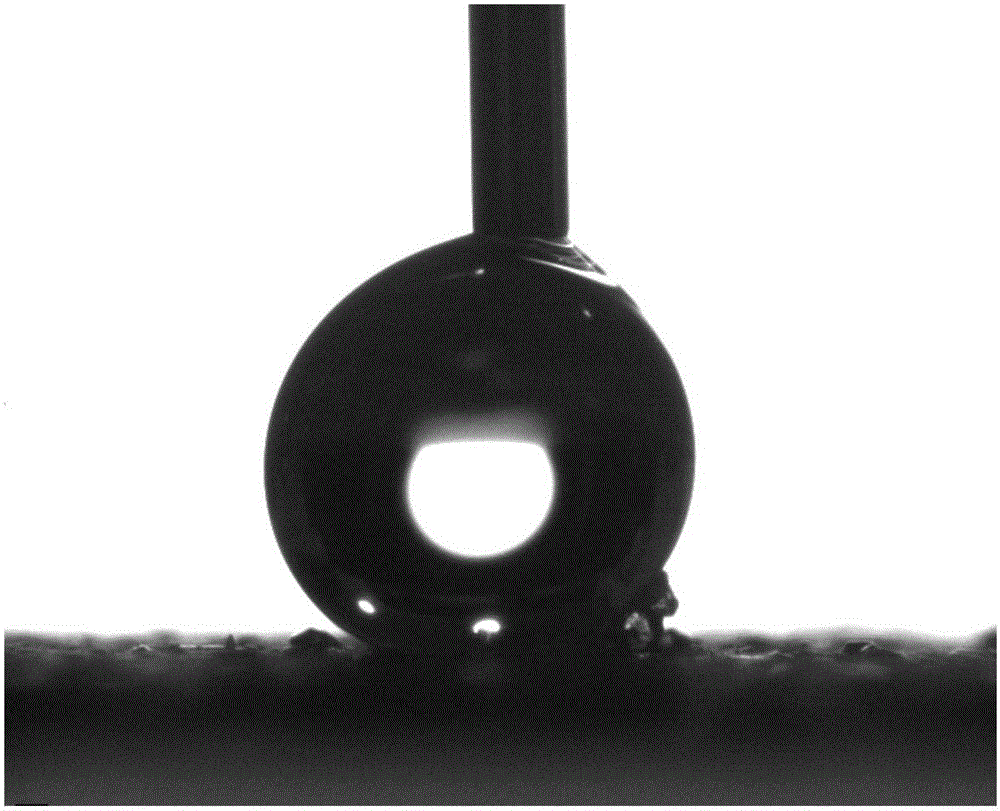

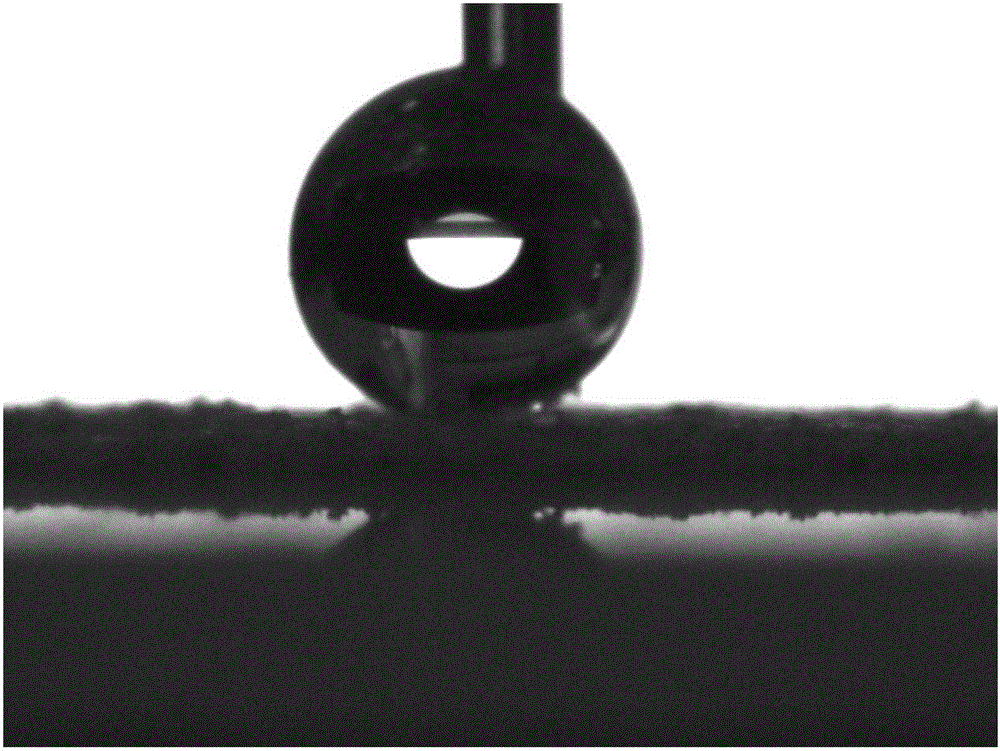

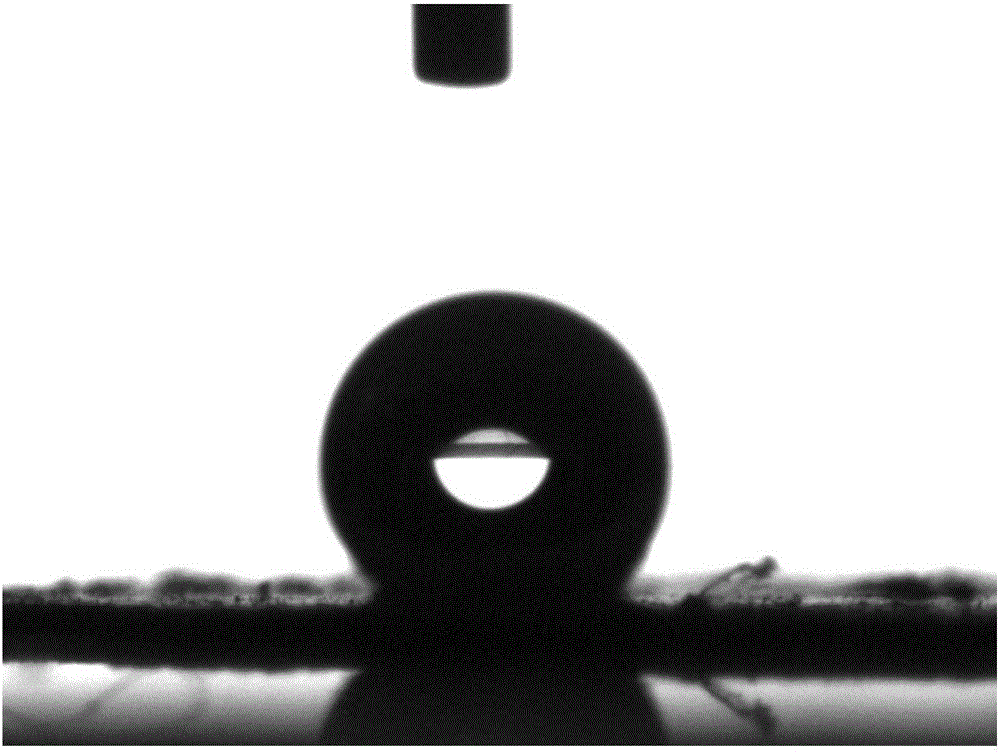

[0028] A preparation method of an energetic material with controllable interface wettability includes the following steps:

[0029] Step 1. Ultrasonic dispersion of HMX particles with a particle size of 180μm in ethanol and water to a concentration of 5mg / ml, ultrasonic cleaning for 10min;

[0030] Step 2: After suction filtering the solid particles cleaned in step 1, they are placed in an oven at 80°C for 6h;

[0031] Step 3. Prepare 40ml of a 10mM tris buffer aqueous solution with a pH value of 8.5. Disperse the solid particles obtained in step 2 into the buffer solution, and add 2mg / mL dopamine hydrochloride to the dispersion Stir for 12h;

[0032] Step 4. The dispersion liquid that was stirred in step 3 was subjected to suction filtration and cleaning, and dried in an oven at 50°C for 5 hours;

[0033] Step 5, the TiO with a particle size of 20nm 2 The particles were added to deionized water at a concentration of 5 mg / ml, the dispersion was ultrasonically dispersed for 10 minutes, ...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment is:

[0039] The solid particles mentioned in step one are RDX of 100 μm. Others are the same as the first embodiment.

Embodiment 3

[0041] The difference between this embodiment and the first embodiment is:

[0042] The solid particles mentioned in step one are 500 μm spherical HMX. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com