Full automatic loader

A car loading machine, fully automatic technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of heavy workload in unstacking and loading, a large number of workers, easy to break and tear bags, etc., to achieve saving Loading time, improve work efficiency, and reduce the effect of manual participation in the loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

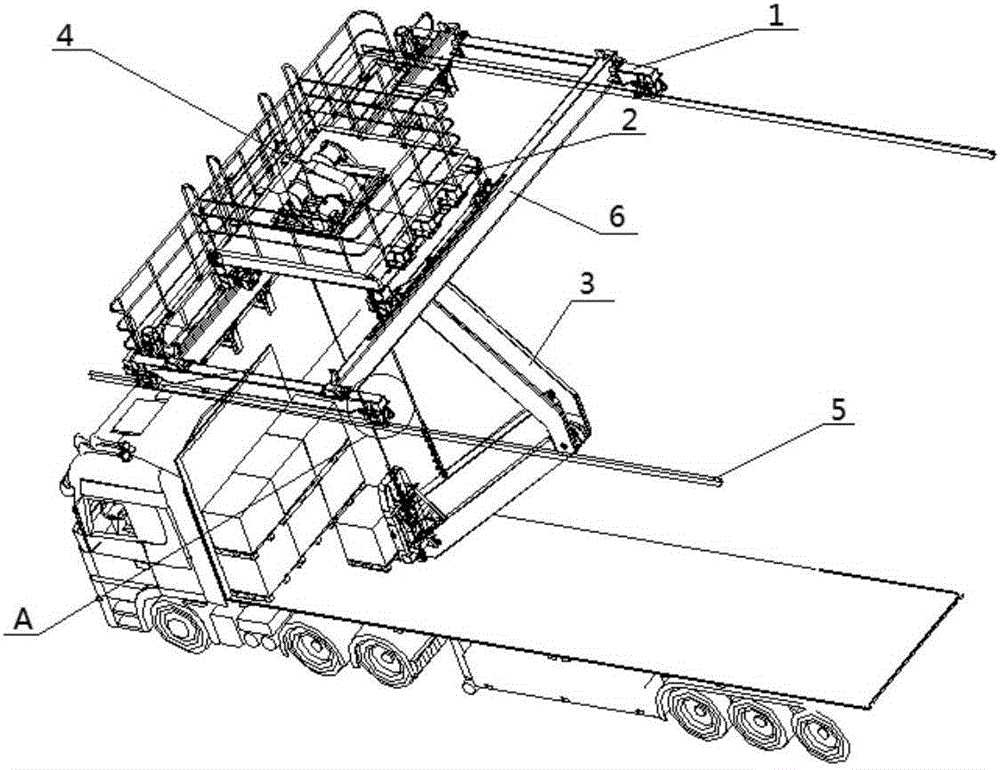

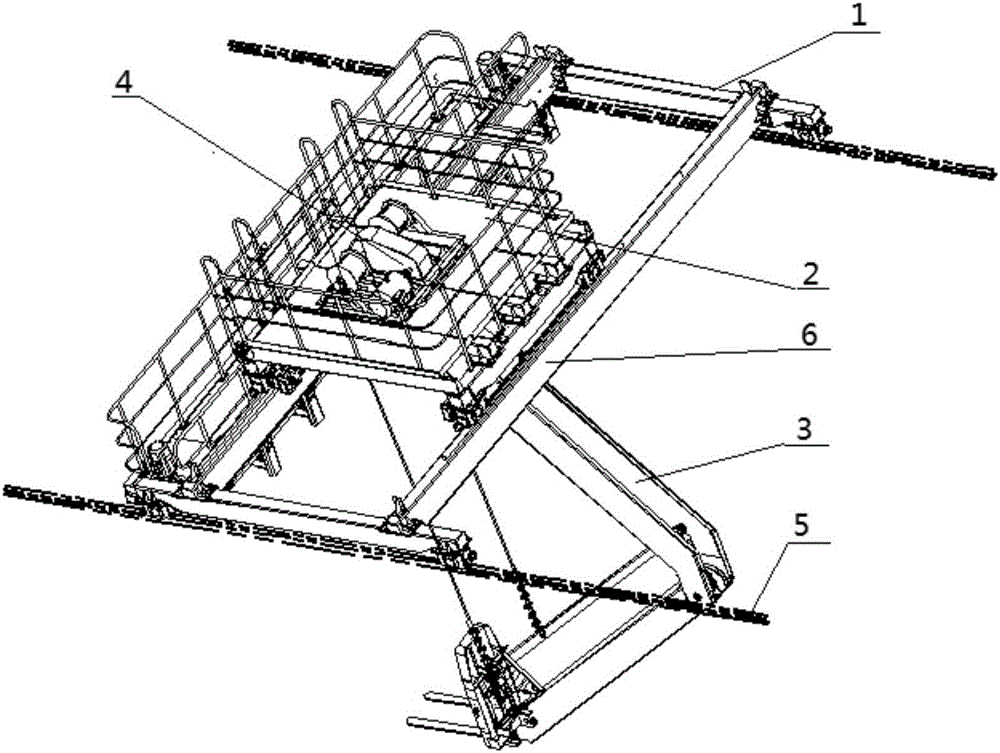

[0030] A fully automatic loading machine, comprising: a track moving cart 1, a lifting device 4, a cart guide rail 5, a trolley guide rail 6, a rail moving trolley 2 and a mechanical arm 3,

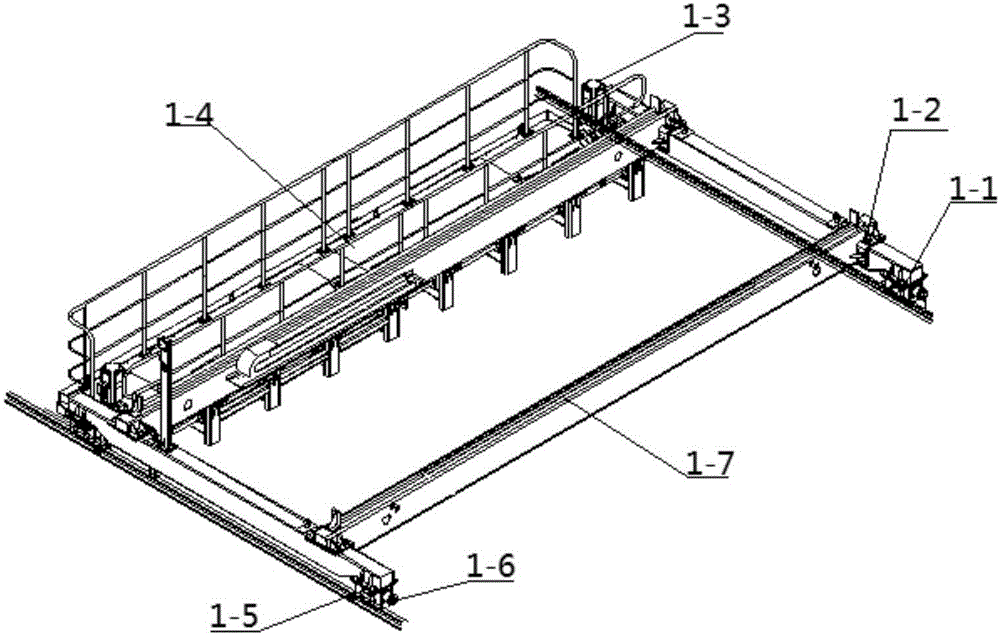

[0031] The track moving cart 1 includes: a cart traveling mechanism 1-1, a cart main frame 1-2 and a cart driving mechanism 1-3;

[0032] A cart traveling mechanism 1-1 is installed at the bottom of the cart main frame 1-2, and the cart driving mechanism 1-3 drives the cart traveling mechanism 1-1 to move linearly along the cart guide rail 5;

[0033] The track moving trolley 2 includes: a trolley main frame 2-1, a trolley running mechanism 2-3 and a trolley driving mechanism 2-6;

[0034] The trolley running mechanism 2-3 is installed at the bottom of the trolley main frame 2-1, and the trolley driving mechanism 2-6 drives the trolley traveling mechanism 2-3 to make a linear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com