Power assembly housing and automobile

A powertrain and integrated housing technology, applied in the powertrain housing and automotive fields, can solve problems such as unfavorable lightweight design, poor positioning effect, and poor vehicle NVH performance, and avoid poor vehicle NVH performance. , Reduce the connection structure and avoid the effect of poor positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments. In the following description, specific details, such as specific configurations and components, are provided only to assist in a comprehensive understanding of the embodiments of the present invention. Accordingly, those of ordinary skill in the art should recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted for clarity and conciseness.

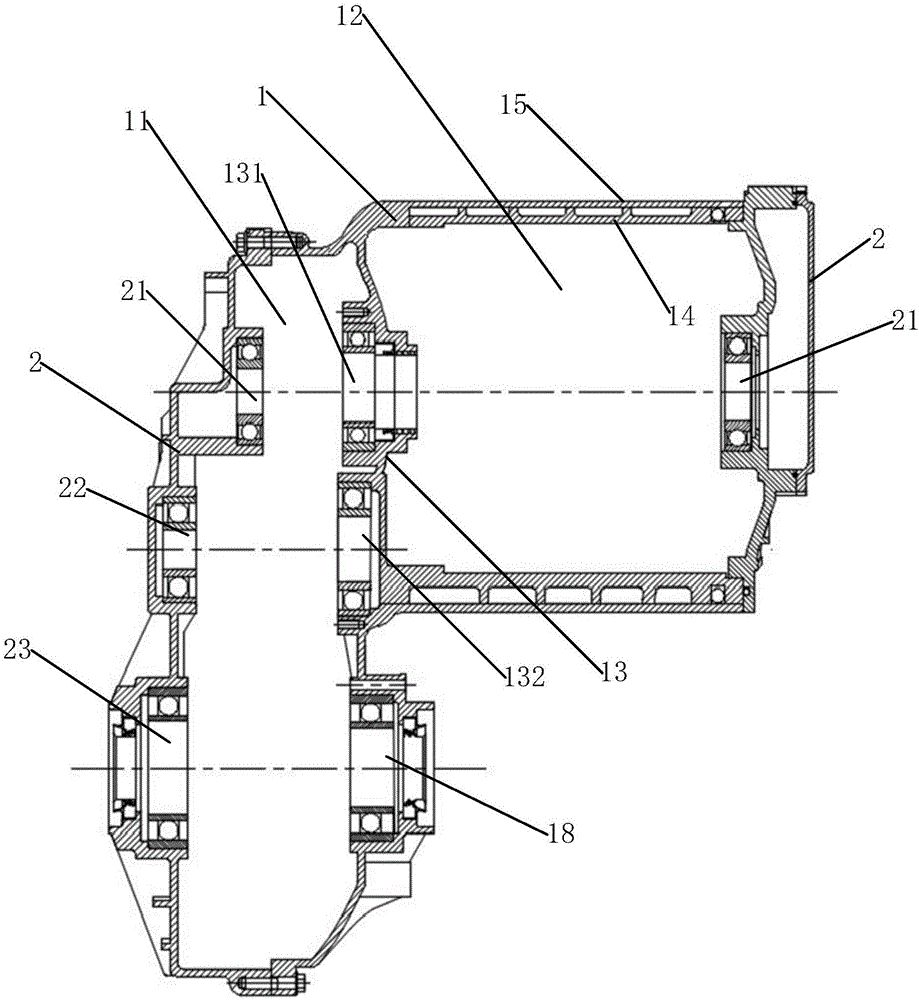

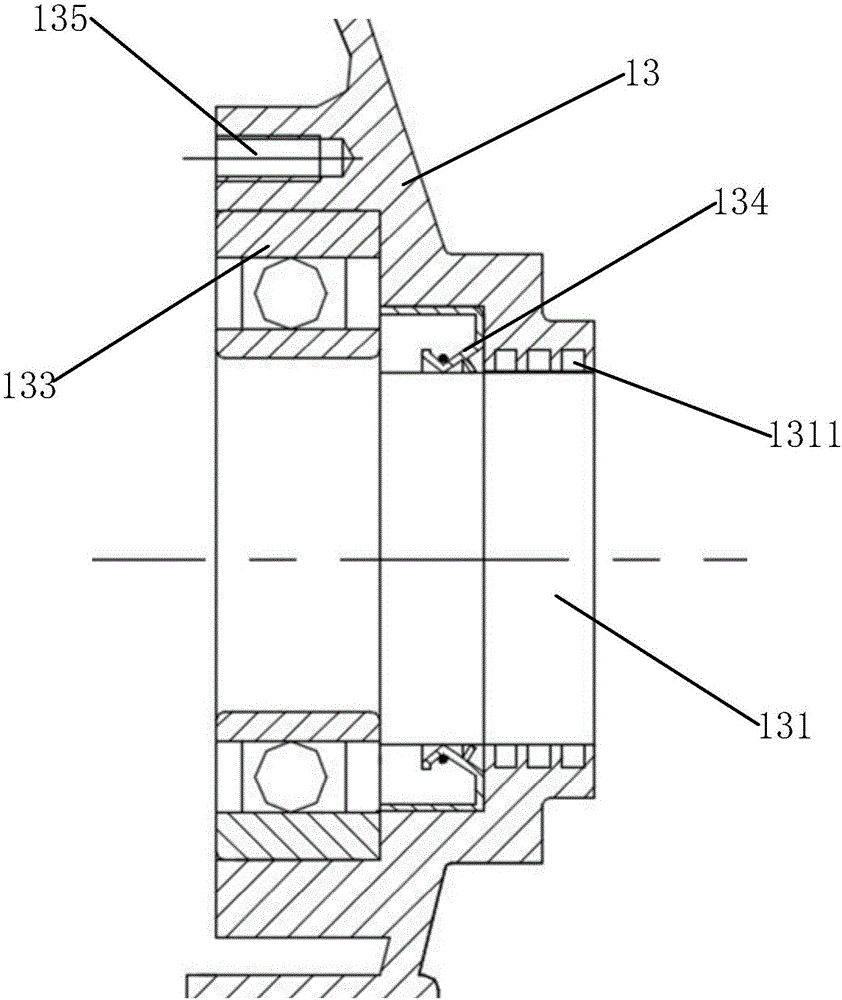

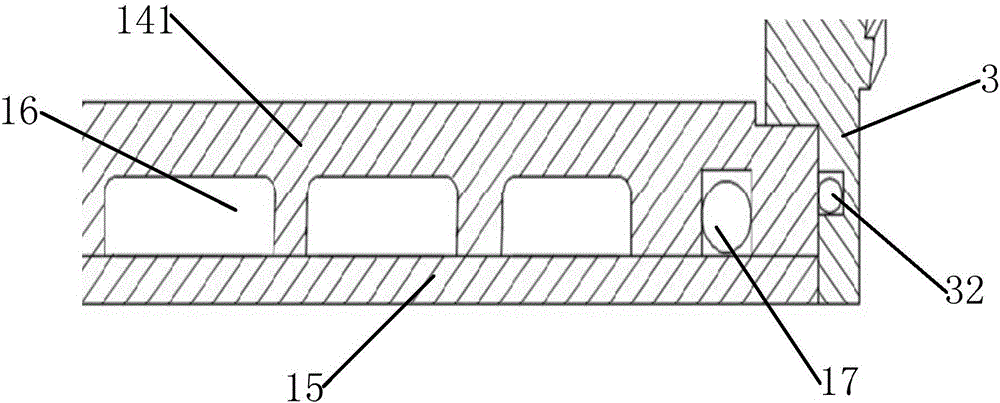

[0032] refer to Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a powertrain housing, an integrated housing 1, including a first installation space 11 for installing the reducer of the motor-reducer integrated ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com