Transferring method for machined workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

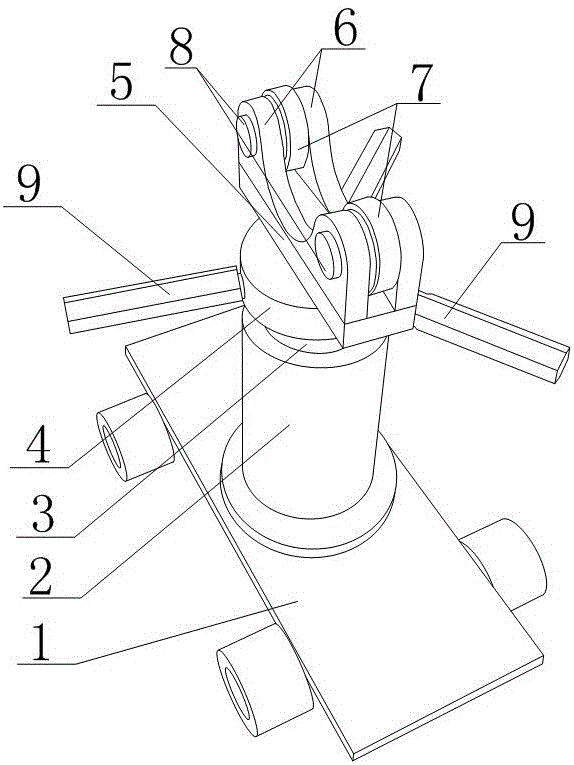

[0019] Such as figure 1 As shown, a workpiece transfer device for mechanical processing of the present invention includes a transfer trolley 1, the transfer trolley 1 is composed of a vehicle body and wheels, a sleeve 2 is arranged on the vehicle body, and the sleeve 2 is sleeved with the sleeve 2 Matching sleeve column 3, the length and diameter of sleeve column 3 are matched with the internal length and inner diameter of sleeve 2, a rotating disk 4 is arranged on the top of sleeve column 3, and three rotating disks are arranged on the side wall of rotating disk 4. Handles 9, three rotating handles are evenly distributed on the side wall of the rotating disk 4, the rotating handle 9 is perpendicular to the axis of the rotating disk 4, the rotating handles 9 are at the same level, and the angle formed by any two rotating disks 4 is 120° °, a workpiece storage device is installed on the rotating disk 4, the workpiece storage device includes a horizontal plate 5, the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com