Collecting device for drill pin ground materials

A technology for collecting devices and grinding materials, which can be applied to other manufacturing equipment/tools, metal processing machinery parts, maintenance and safety accessories, etc. The effect of broken needle and rod injury, reducing labor intensity and reducing product quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

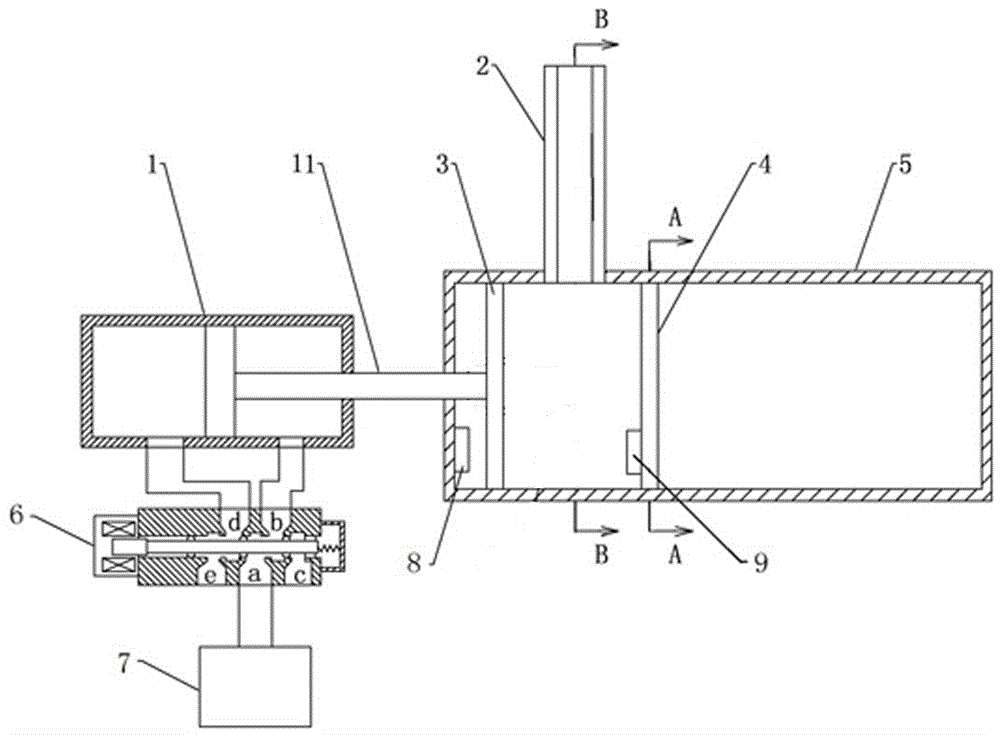

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

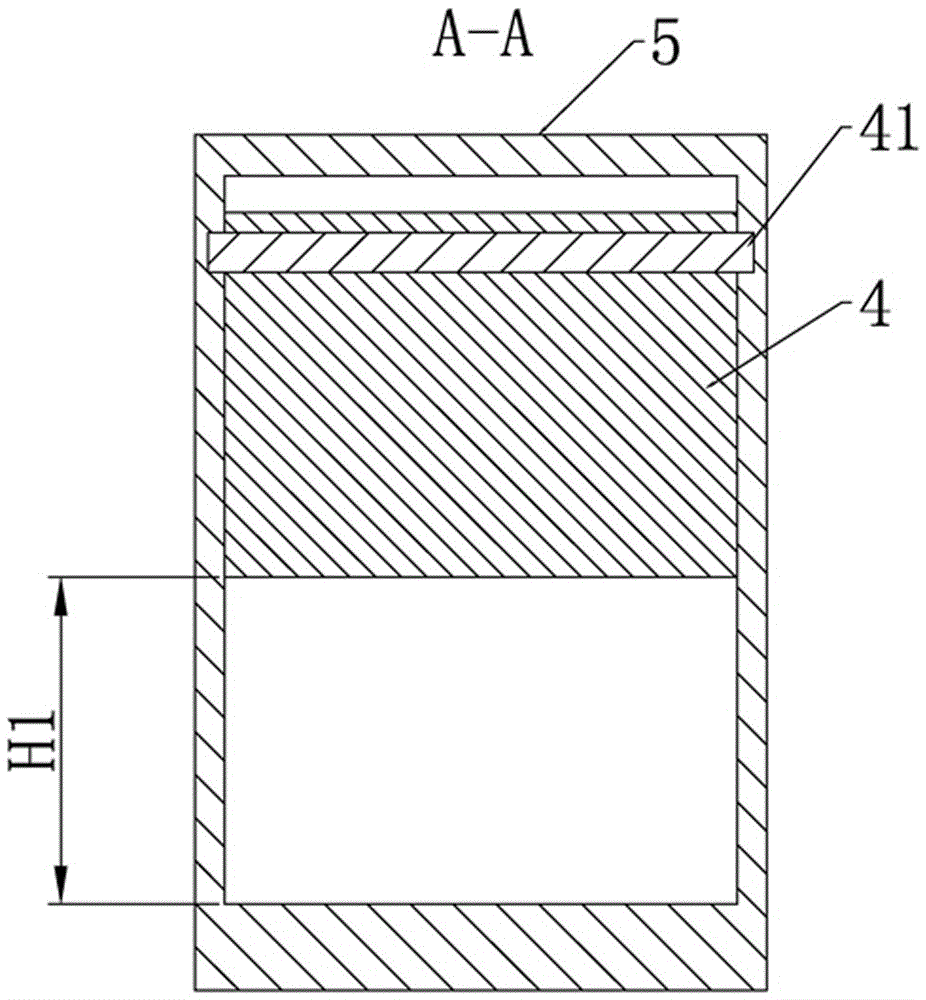

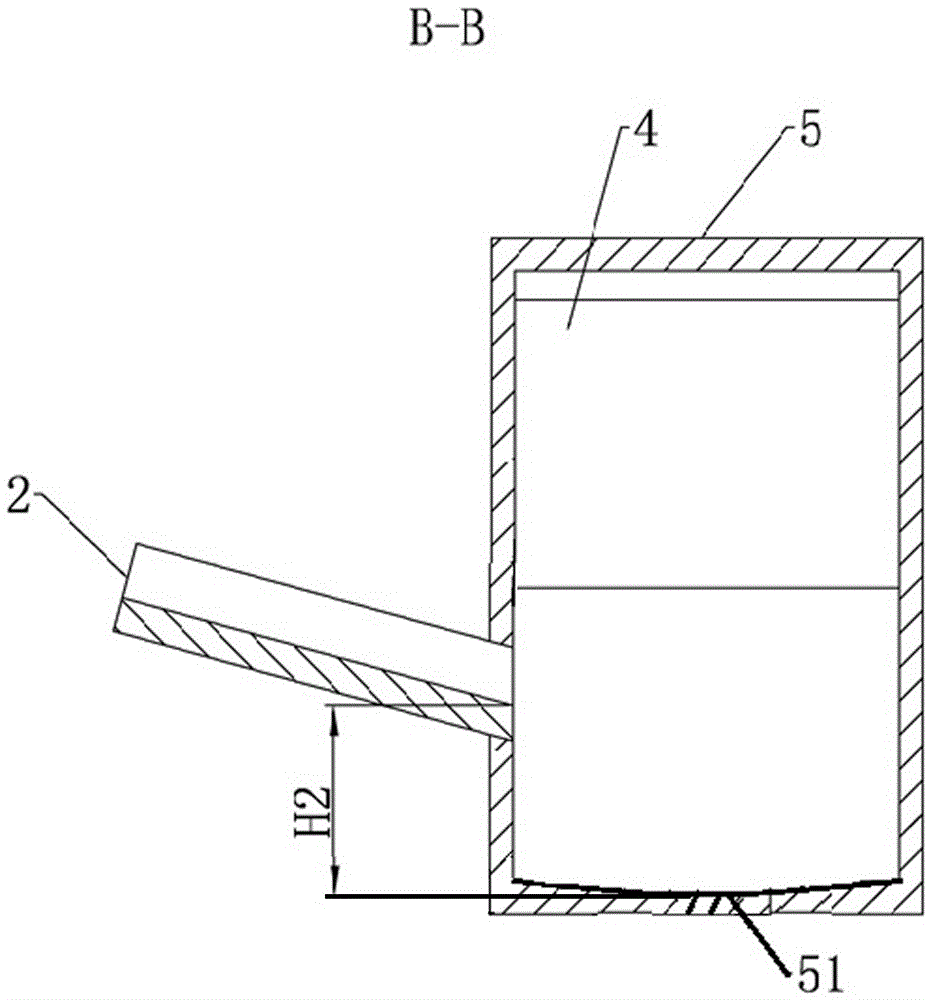

[0026] The specific embodiment of the present invention sees Figure 1-5 , a drill grinding material collection device, the device is arranged under the rotation mechanism 21 and the grinding wheel cutting mechanism 23 of the PCB drill 22 rough grinding device, and the rotation mechanism 21 is equipped with a number of PCB drills with a diameter of 2.975cm Needle 22, the device includes a material guide mechanism, a material receiving body 5, a material pushing mechanism, and a material blocking mechanism;

[0027] One side of the receiving body 5 is provided with a material guiding mechanism, and the material guiding mechanism includes a material guiding groove 2, and one end of the material guiding groove 2 communicates with the side of the material receiving body 5;

[0028] Described pusher mechanism comprises pusher cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com