Transformer for test

A technology for transformers and tests, applied in the direction of transformers, variable transformers, transformer/inductor cores, etc., can solve the problems of difficult adjustment and difficult operation of transformers, and achieve convenient use, convenient electromagnetic coupling needs, and reduced costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

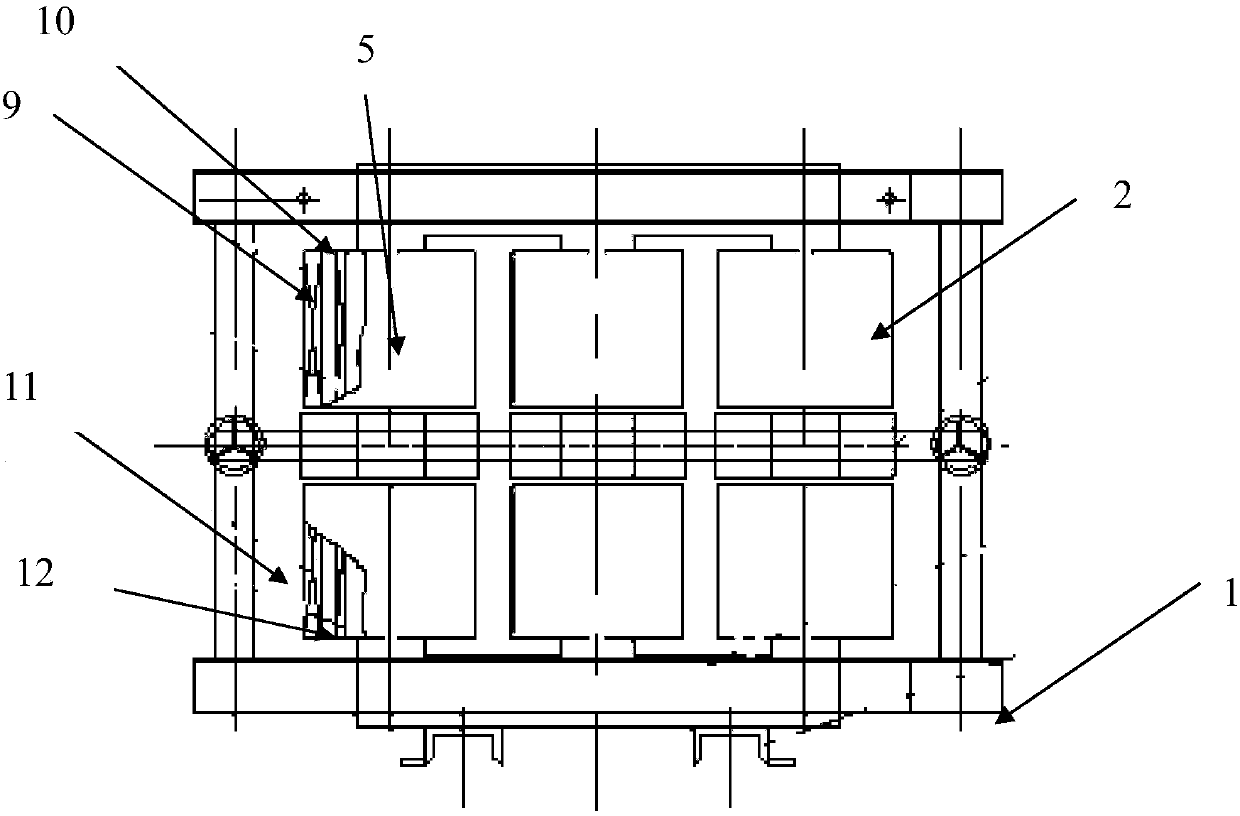

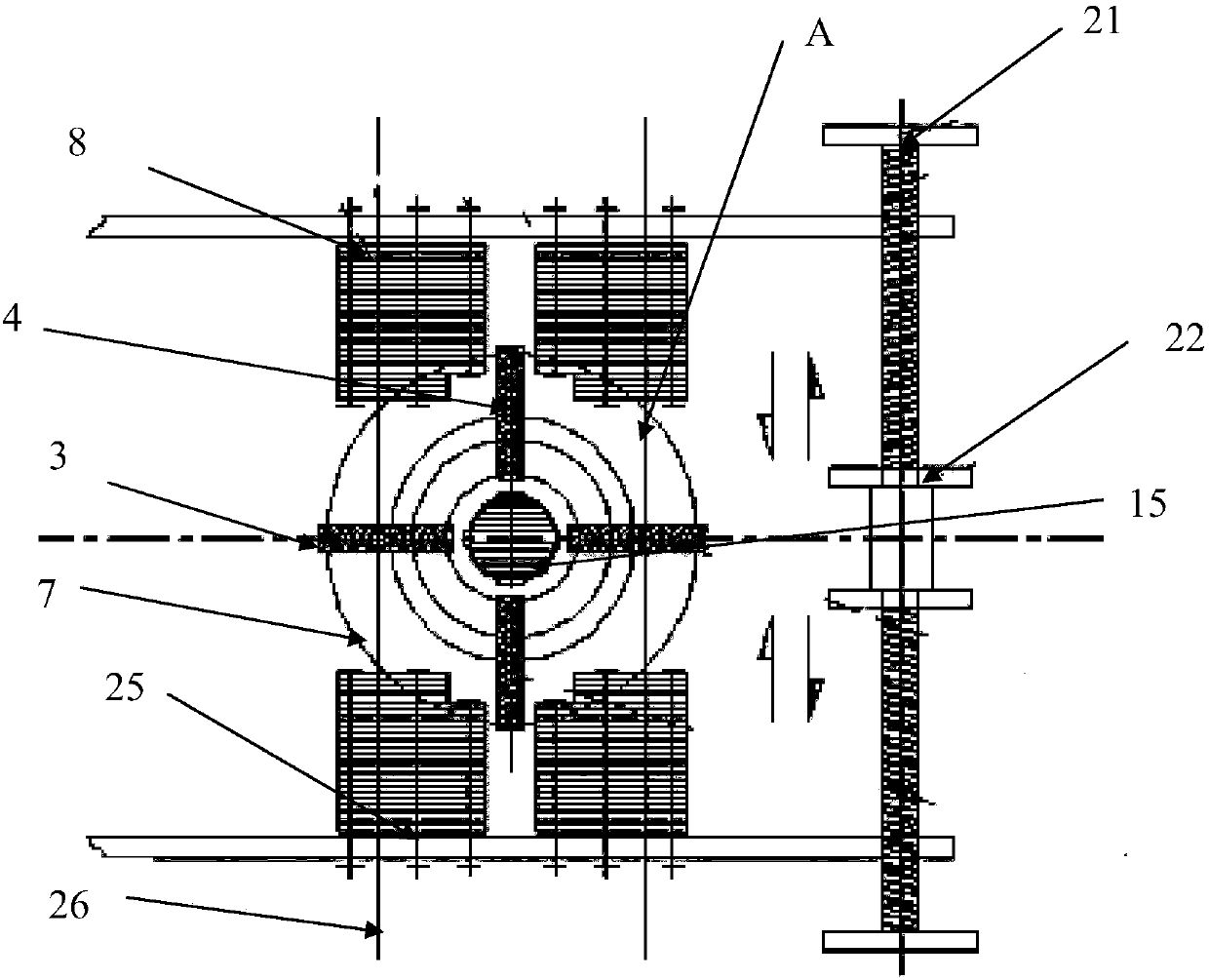

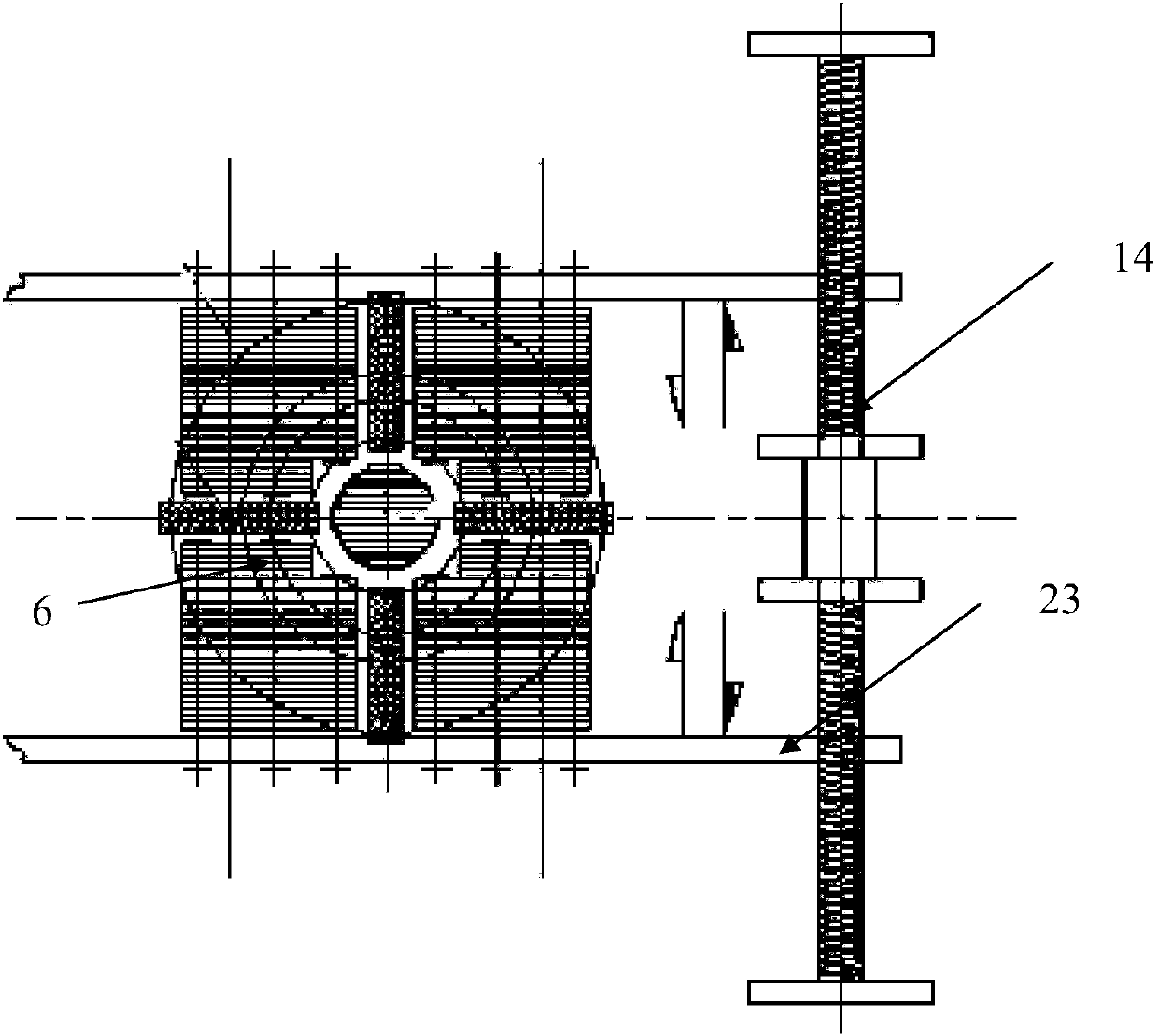

[0024] Embodiment: the present invention also discloses a kind of test transformer (see attached figure 1 , 2 , 3), including: support 1, iron core 5 groups 2 and phase electromagnetic coupling assembly 6; said iron core 5 groups 2 are installed on the support 1; said iron core 5 groups 2 include a plurality of iron cores 5; said The middle part of the iron core 5 has a pair of first insulating spacers 3 arranged along the length direction of the transformer and a pair of second insulating spacers 4 arranged along the width direction of the transformer; a pair of first insulating spacers 3 and a pair of second insulating spacers The insulating pads 4 intersect to form insulating groups 7 arranged in a cross shape;

[0025] The phase electromagnetic coupling assembly 6 includes a phase electromagnetic coupling iron core 15 and four groups of laminations 8; the phase electromagnetic coupling iron core 15 is arranged at the center of the cross-shaped insulating group 7; the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com