Method and system for measuring relative humidity at high temperature and high pressure

A technology of relative humidity, high temperature and high pressure, applied in the direction of material electrochemical variables, etc., can solve the problems that the temperature is not constant and incompetent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

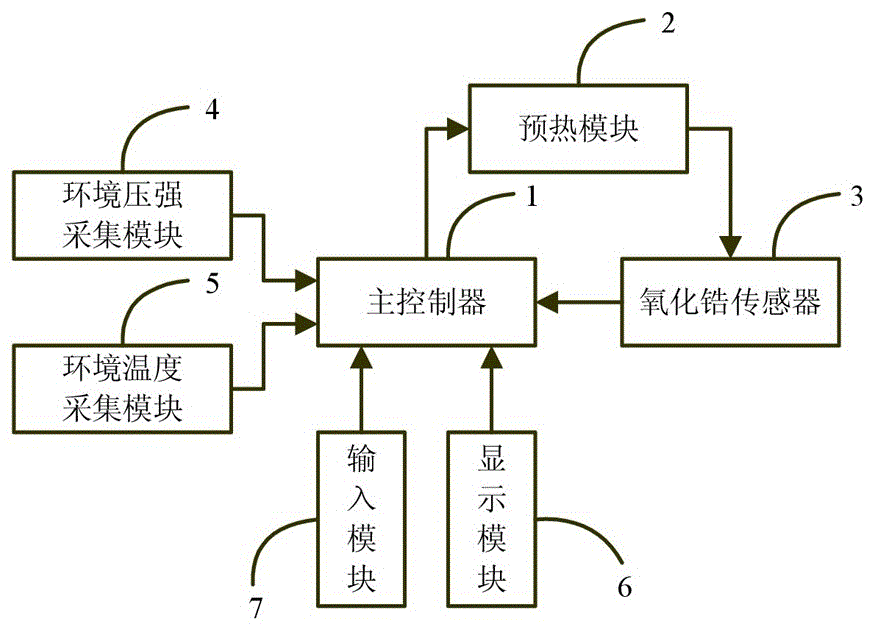

[0055] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

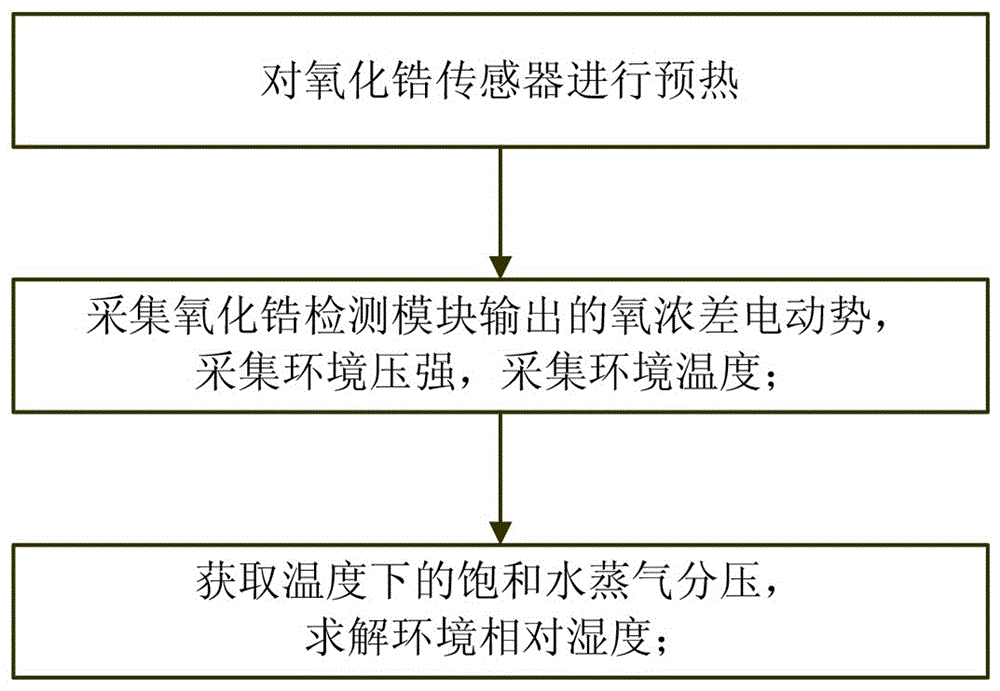

[0056] Such as figure 1 As shown, in the first embodiment of the present invention, a method for measuring relative humidity at high temperature and high pressure is provided, comprising the following steps:

[0057] S1. Collect the electromotive force E of oxygen concentration difference output by the zirconia sensor, and collect the ambient pressure P environment , to collect the ambient temperature t;

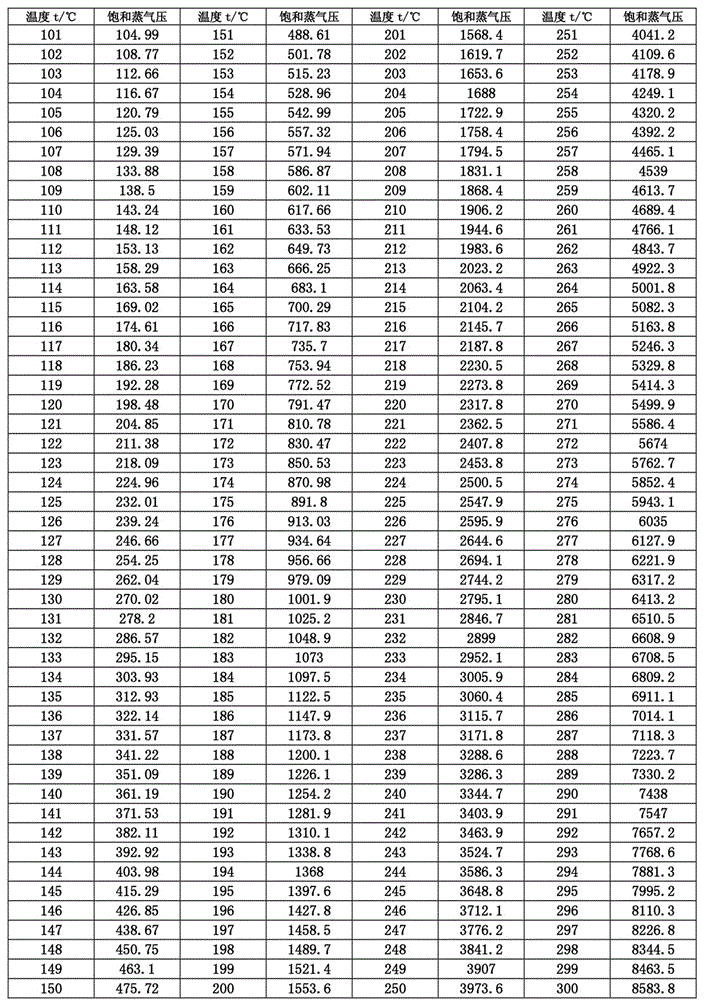

[0058] S2. Obtain the saturated water vapor partial pressure P at temperature t m , to solve the relative humidity RH of the environment;

[0059] Among them, R is the ideal gas constant 8.314J mol -1 ·K -1 , the T is the absolute temperature value (K), and the F is the Faraday constant 96500c·mol -1 , the P m is the partial pressure of saturated water vapor at the current ambient temperature t.

[0060] It is worth mentioning that the ambient pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com