Fabricated type concrete foundation and installation method thereof

A concrete and prefabricated technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of aggravating frost heaving and thawing of the permafrost foundation of transmission lines, affecting the safe operation of transmission lines, and damaging bolts and threads, etc., so as to improve the strength and Freeze resistance, simple structure, and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

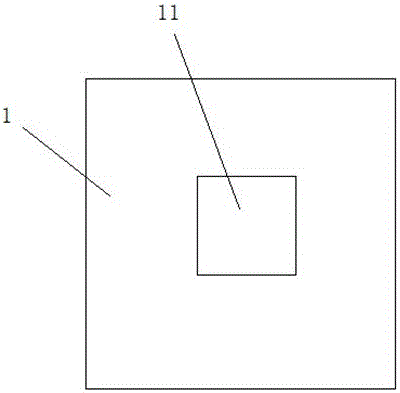

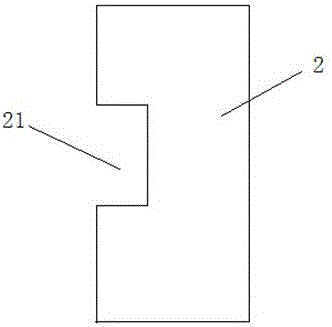

[0027] Such as figure 1 As shown, the concrete prefabricated foundation of the present invention includes a chassis 1 , two bottom plates 2 with the same size and shape, and foundation columns 3 . The chassis 1 and the foundation column 3 are respectively fixed to the bottom plate 2 by bolts.

[0028] combine Figure 2 to Figure 4 , The center of the chassis 1 is provided with a square bump 11 . A notch 21 is provided at the center of one side of the bottom plate 2; two bottom plates 2 are spliced together, and the protrusion 11 of the chassis 1 is stuck in the spliced notch 21, and the bottom plate 2 and the chassis 1 are fixed by bolts. The foundation column 3 includes a hollow cylinder 31 at the lower end and a truncated cone 32 at the upper end. The foundation column 3 is sleeved on the protrusion of the chassis through the hollow cylinder 31 at the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com