Deep-layer stirring pile equipment for soil restoration and construction method thereof

A technology for deep mixing piles and soil remediation, applied in the field of soil remediation, can solve the problems of high cost, low construction efficiency, complicated procedures, etc., and achieve the effects of small impact, short treatment period and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

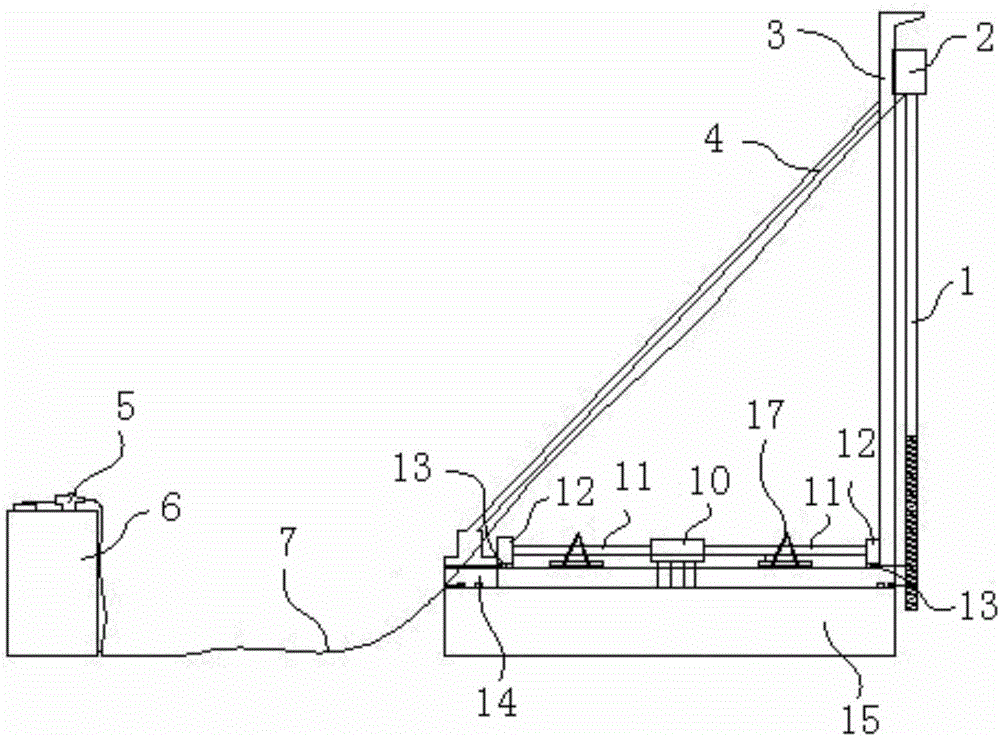

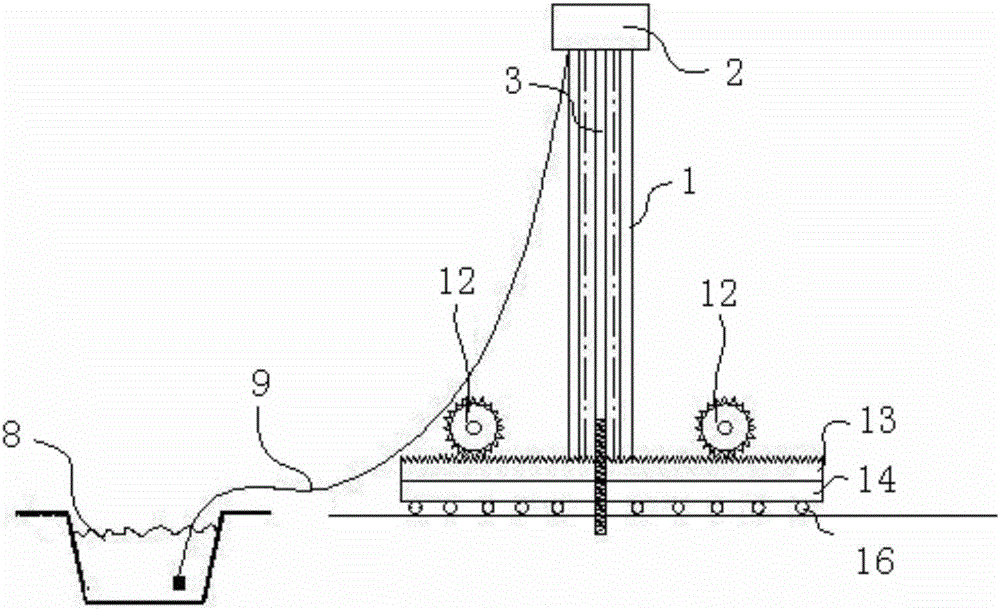

[0034] see figure 1 and figure 2 , the deep stirring pile equipment shown in the illustration is a preferred embodiment of the present invention, and specifically includes three parts: a drill pipe assembly, a drug delivery assembly and a grouting assembly.

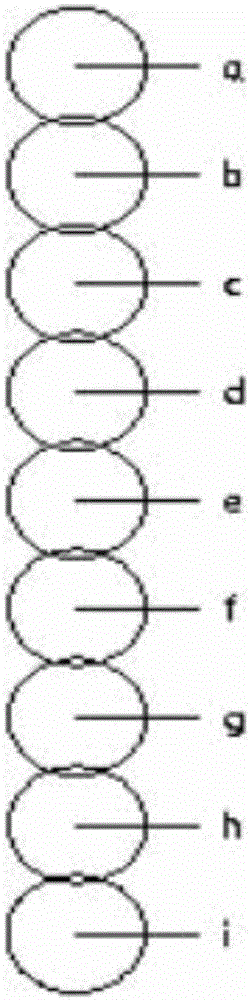

[0035] Wherein the drill pipe assembly includes a drill pipe 1, a drill pipe linkage motor 2, a drill pipe lifting column 3, and a drill pipe support 4. The drill pipe 1 adopts a hollow drill pipe, and the head end of the drill pipe is provided with an auger for drilling and mixing soil. The tail end of the rod is connected with the drill pipe linkage motor 2, and is installed together on the drill pipe lifting column 3. The drill pipe lifting column 3 is vertically arranged on the drill pipe support 4, and a winch mechanism for lifting the drill pipe is provided on it. The hoisting mechanism is relaxed, and the drill pipe is cut and mixed with the soil from top to bottom under the action of the drill pipe linkage motor...

Embodiment 2

[0044] This example illustrates the construction method for soil remediation using the deep-layer mixing pile equipment in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com