A kind of iron-nickel alloy-low carbon steel composite material and preparation method thereof

An iron-nickel alloy and composite material technology, applied in the field of metal composite materials, can solve the problems of not too thick coating, particle agglomeration, difficult to control, etc., and achieve the effect of reducing diffusion resistance, increasing diffusion speed, and compact surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

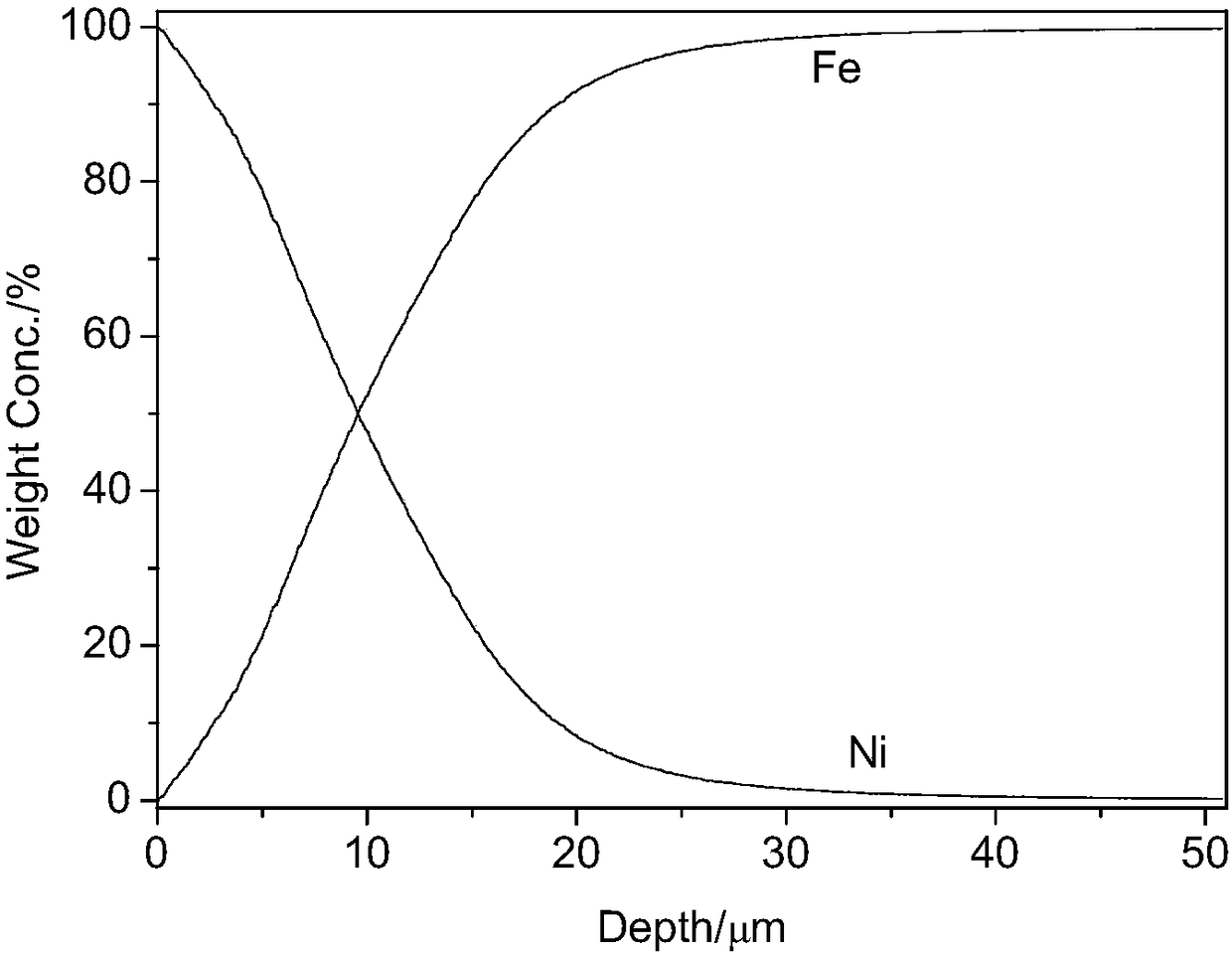

[0025] Such as Figure 4 As shown, embodiment 1 of the present invention provides a kind of iron-nickel alloy-low carbon steel composite material, and its structure is low carbon steel matrix and the iron-nickel alloy layer that is compounded on the low carbon steel matrix, and the thickness of iron-nickel alloy layer is 50 μ m , in the iron-nickel alloy layer, from the low-carbon steel substrate to the direction of the iron-nickel alloy layer, the Ni content gradient increases, and the Fe content gradient decreases, and its preparation method is implemented according to the following steps:

[0026] Step 1. Pretreatment of low carbon steel plate

[0027] First, use a low-carbon steel plate with a length and width of 20mm and a thickness of 1mm as the substrate, select a low-carbon steel with a carbon content of 0.02%, and polish the low-carbon steel plate with 200-2000# sandpaper in turn until a mirror effect appears, and use hydrochloric acid Soak the polished low-carbon st...

Embodiment 2

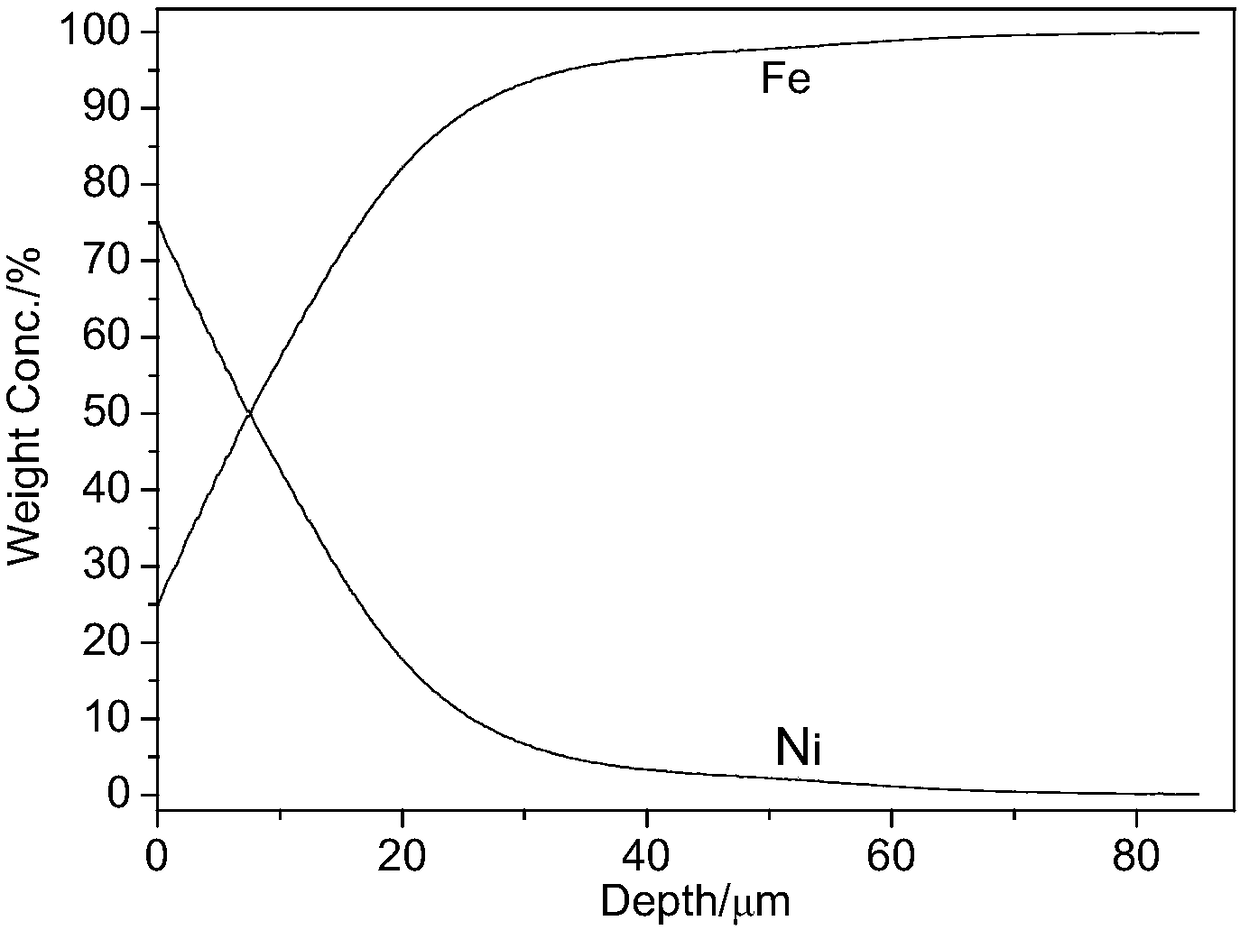

[0034] Embodiment 2 of the present invention provides a kind of iron-nickel alloy-low carbon steel composite material, and its structure is low carbon steel substrate and the iron nickel alloy layer that is compounded on the low carbon steel substrate, and the thickness of iron nickel alloy layer is 85 μm, and iron nickel In the alloy layer, from the low-carbon steel substrate to the direction of the iron-nickel alloy layer, the Ni content gradient increases and the Fe content gradient decreases, and its preparation method is implemented according to the following steps:

[0035] Step 1. Pretreatment of low carbon steel plate

[0036] First, use a low-carbon steel plate with a length and width of 50mm and a thickness of 10mm as the substrate, select a low-carbon steel with a carbon content of 0.10%, and polish the low-carbon steel plate with 200-2000# sandpaper in turn until a mirror effect appears, and use hydrochloric acid Soak the polished low-carbon steel plate in a mixed ...

Embodiment 3

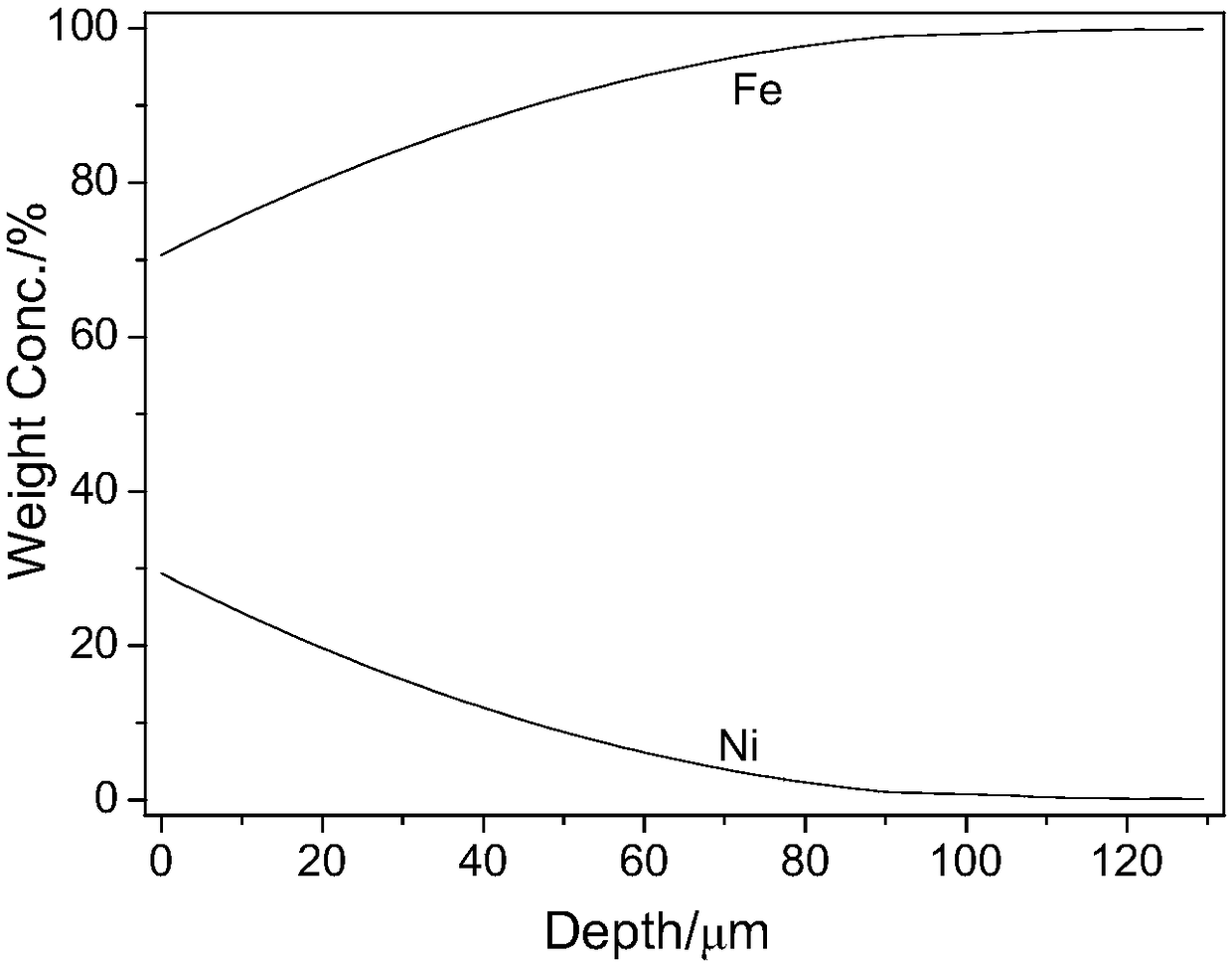

[0043] Embodiment 3 of the present invention provides an iron-nickel alloy-low carbon steel composite material, which has a structure of a low carbon steel substrate and an iron-nickel alloy layer compounded on the low-carbon steel substrate, the thickness of the iron-nickel alloy layer is 130 μm, and the iron-nickel alloy layer is In the alloy layer, from the low-carbon steel substrate to the direction of the iron-nickel alloy layer, the Ni content gradient increases and the Fe content gradient decreases, and its preparation method is implemented according to the following steps:

[0044] Step 1. Pretreatment of low carbon steel plate

[0045] First, use a low-carbon steel plate with a length and width of 100mm and a thickness of 20mm as the substrate, select low-carbon steel with a carbon content of 0.25%, and polish the low-carbon steel plate with 200-2000# sandpaper in turn until a mirror effect appears, and use hydrochloric acid Soak the polished low-carbon steel plate in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com