Fuel filler assembly and manufacturing method thereof

A technology of assembly and fuel filler, which is applied in the direction of power plant, transportation and packaging, vehicle parts, etc., can solve problems such as fire hazards, and achieve the effect of preventing fire and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail with reference to the following drawings. However, this embodiment is not limited to the embodiments disclosed below, but can be realized in various ways. Only this embodiment is intended to make the disclosure of the present invention complete and fully inform the scope of the invention to those skilled in the art to which the present invention pertains. The shapes of elements in the drawings may be exaggerated for clearer description, and the same reference numerals denote the same elements in the drawings.

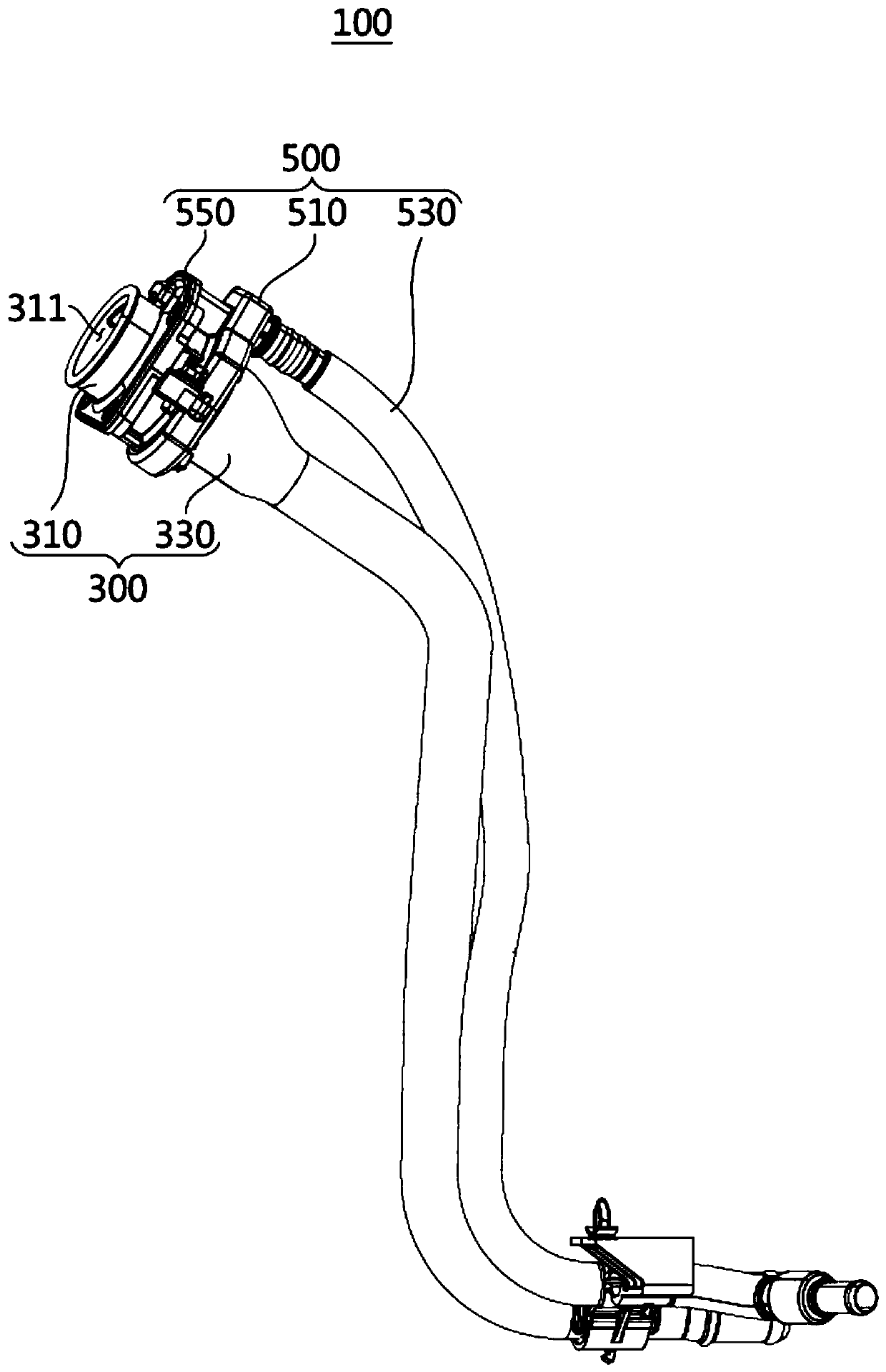

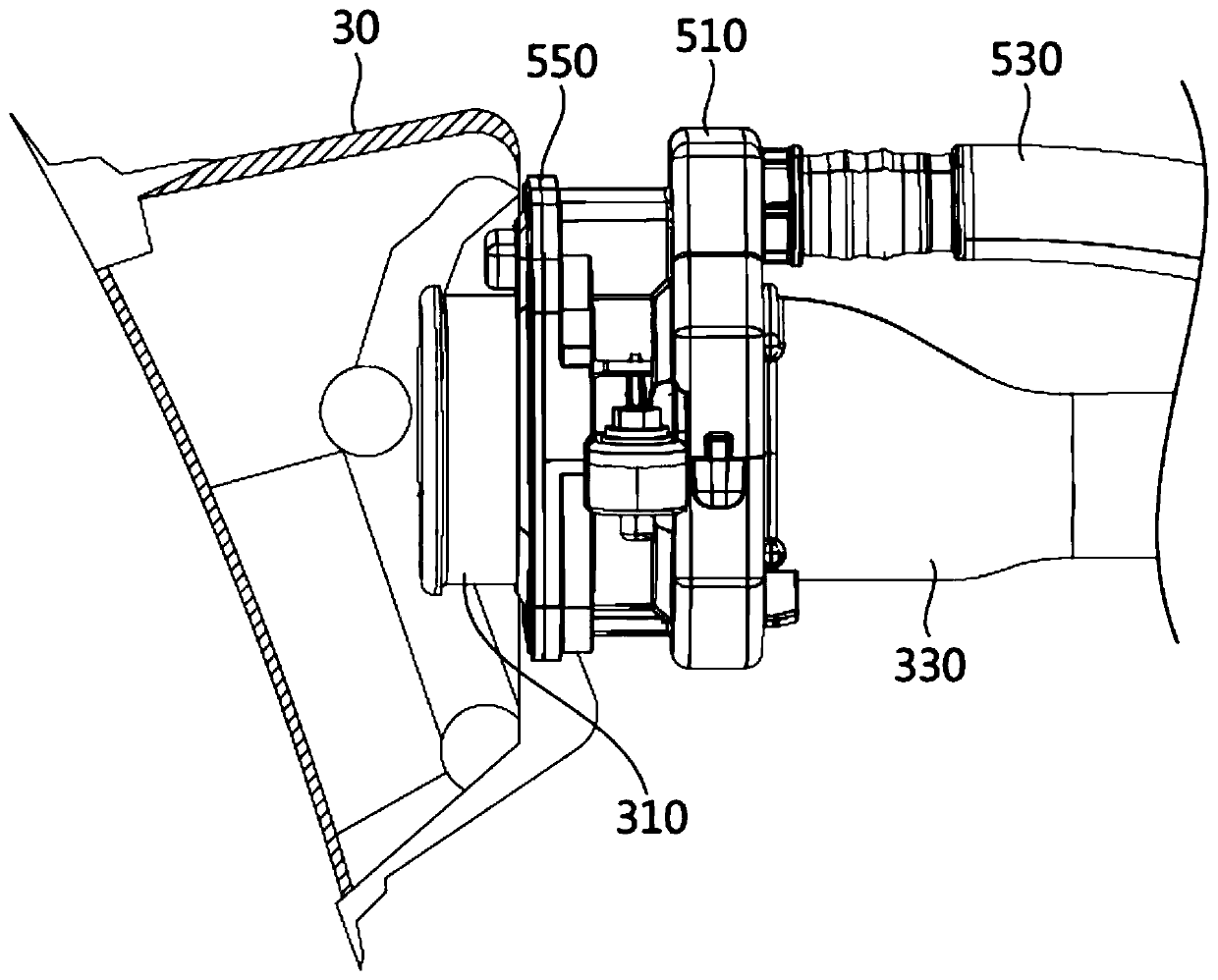

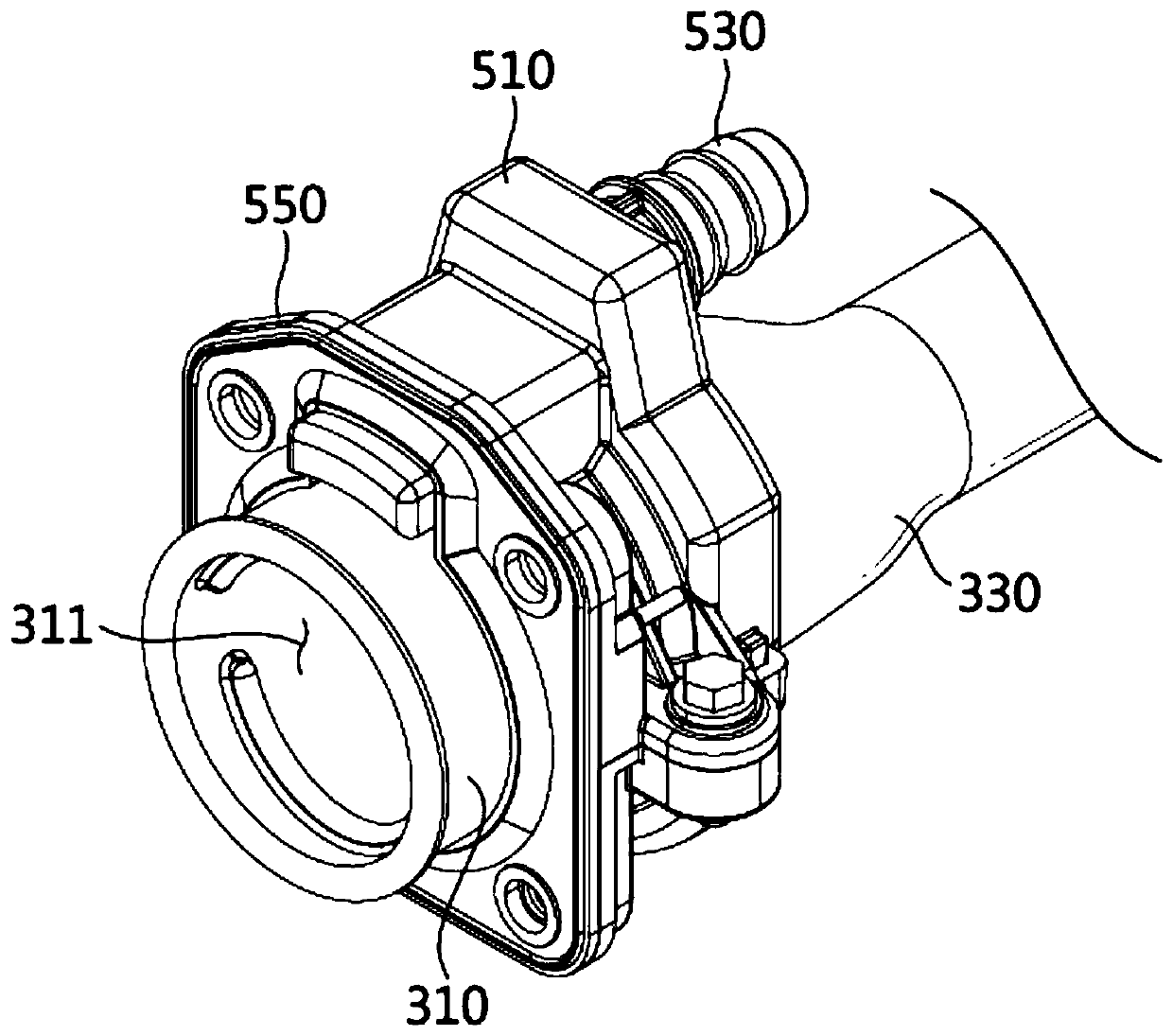

[0037] figure 1 It is a perspective view showing the fuel filler assembly according to this embodiment.

[0038] Such as figure 1 As shown, a fuel gun (not shown) is inserted into the fuel filler assembly 100 according to this embodiment. Wherein, the fuel filler assembly 100 may include: a fuel supply part 300 for transferring fuel from a fuel filler gun to the fuel tank; an air supply part 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com