Feeding and discharging device for silicon ingot cast ingot crucible spraying

A technology of crucible spraying and ingot casting, which is applied in the direction of spraying devices, etc., which can solve the problems of inconvenient operation, time-consuming and labor-intensive, easy damage, etc., achieve the effect of guarantee, facilitate loading and unloading operations, and improve applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

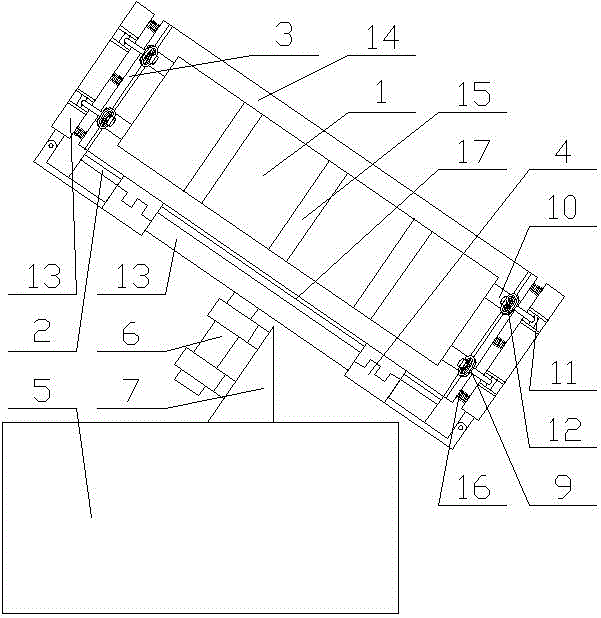

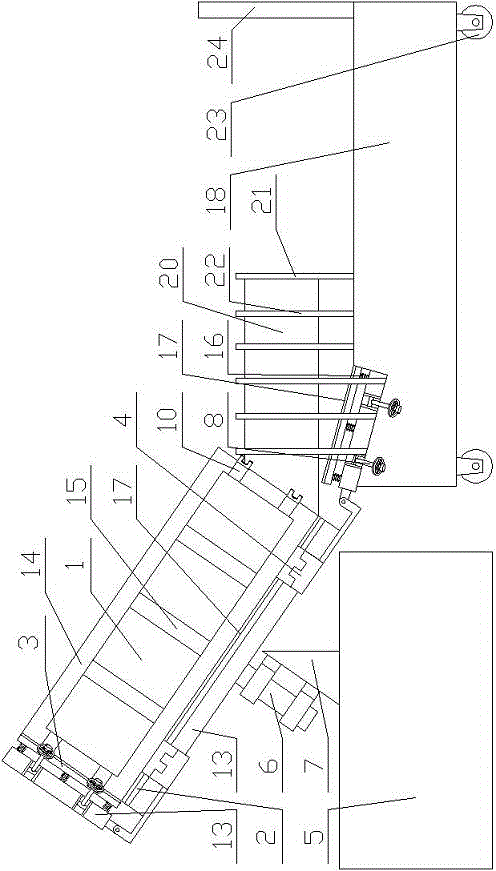

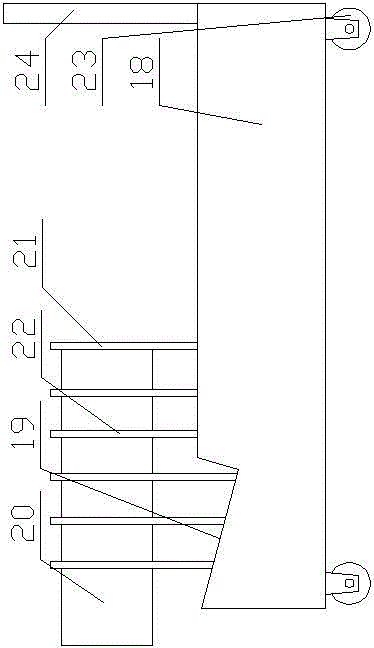

[0037] combine Figure 1~Figure 4 As shown, the present invention includes a crucible fixing groove 1, the sides of the bottom plate 2 of the crucible fixing groove 1 are respectively connected to the side plates 3 through hinges 4, and the side plates 3 are fixed by a locking structure, and the bottom plate 2 It is fixed on the top of the rotating shaft 6, and is rotatably connected with the base 5 through the rotating shaft 6. The shaft body of the rotating shaft 6 is arranged obliquely upward; The top surface of the car body 18 is provided with a side plate groove 19 facing the side of the crucible fixing groove 1, and when the side plate 3 positioned at the side below the crucible fixing groove 1 is opened and separated from the adjacent two side plates 3, it will be separated from the adjacent two side plates 3. The side plate groove 19 is in contact with, and adheres to the groove wall of the side plate groove 19 .

[0038] The height of the plane where the top surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com