An online optimization and adjustment method for the start-up curve of a gas-steam combined cycle unit

A combined cycle unit, gas steam technology, applied in design optimization/simulation, instrumentation, calculation, etc., can solve the problems of not taking into account the continuous change of metal temperature, the different durations of the steam turbine warm-up phase and the low-load holding phase, etc. The effect of reducing economic operation cost and improving peak shaving response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

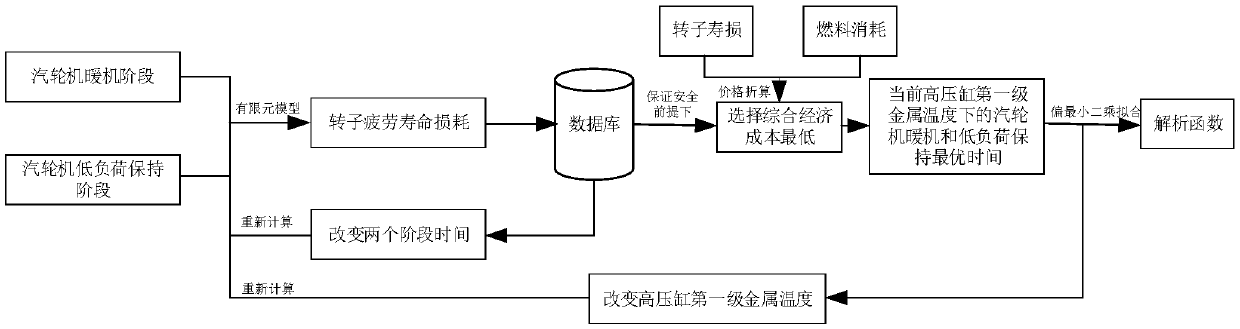

[0037] An online optimization and adjustment method for the start-up curve of a gas-steam combined cycle unit is described in detail below, such as image 3 Shown is the online optimization analytical function solution flow chart of the start-up process of the gas-steam combined cycle unit, including the following steps:

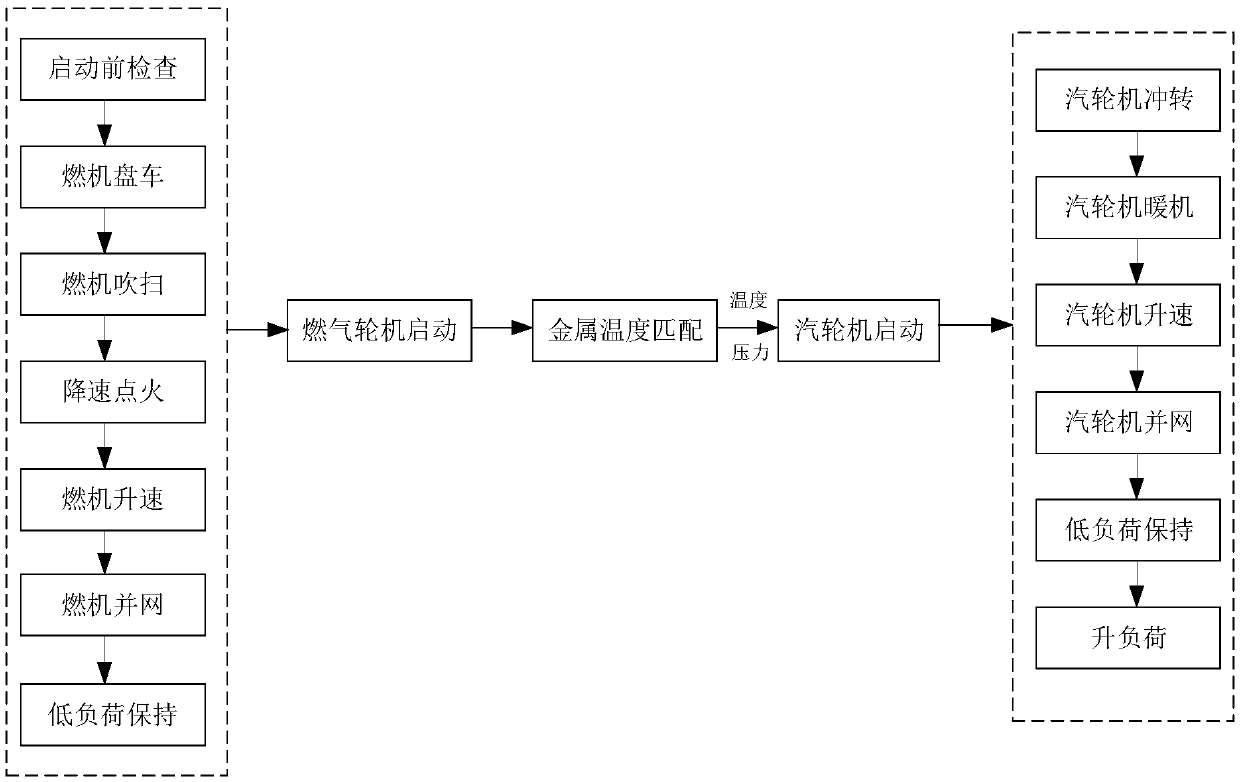

[0038] Step 1. The start-up process of the gas-steam combined cycle unit is divided into stages according to the rotor speed and load conditions, according to figure 1 It can be seen that the start-up process is divided into: gas turbine cranking stage, gas turbine start-up purge stage, gas turbine grid connection, gas turbine low load maintenance stage, steam turbine run-in stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com