Auxiliary paper feeding device for sealing

A technology of paper feeding device and stamping platform, which is applied in the direction of stacking receiving device, transportation and packaging, thin material processing, etc. It can solve the problems of unrecognizable and stamped, the accuracy rate cannot reach 100%, and the speed of recognizing paper is slow. To achieve the effect of improving stamping efficiency, rapid response and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment the present invention is described in further detail:

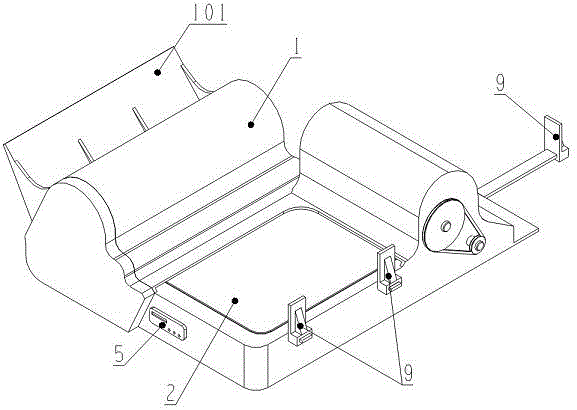

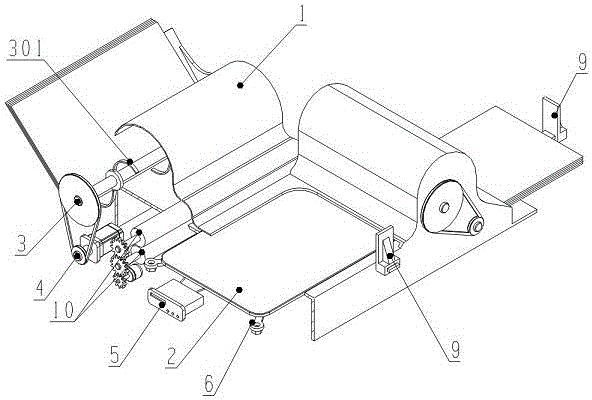

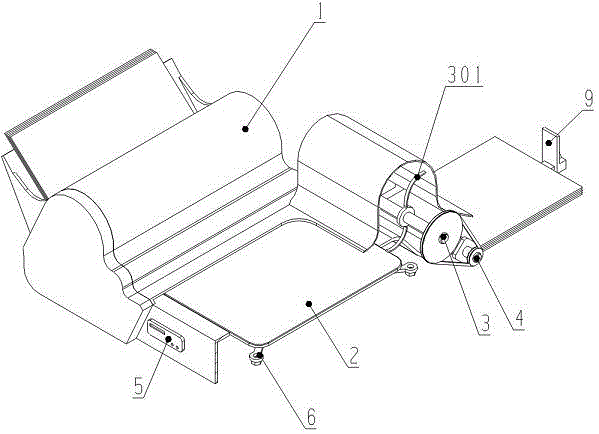

[0027] Such as Figure 1 to Figure 4 As shown, the present invention is an auxiliary paper feeding device for improving the efficiency of stamping, which can effectively improve the work efficiency of stamping, and provide a stable and efficient working environment for manual identification of stamping positions.

[0028] The present invention includes a casing 1 made of hard plastic, and a stepping paper feeding mechanism is installed on one side inside the casing 1 . For the right-handed staff, the paper feeding mechanism is designed on the left; for the left-handed staff, the paper feeding mechanism can be designed on the right. A paper feeding port 101 for accommodating paper bundles is provided outside the stepping paper feeding mechanism. A step-in and paper-out mechanism is installed on the inner rear side of the housing 1 .

[0029] The structure of the stepping paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com