Stern slipway type work boat launching and restoring device

A retractable device and slideway-type technology, which is applied to the direction of the device used to guide the ship to the water surface, can solve the problems of slow retractable speed, large safety hazards, slowness, etc., and achieve reduced possibility, strong reliability, and device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

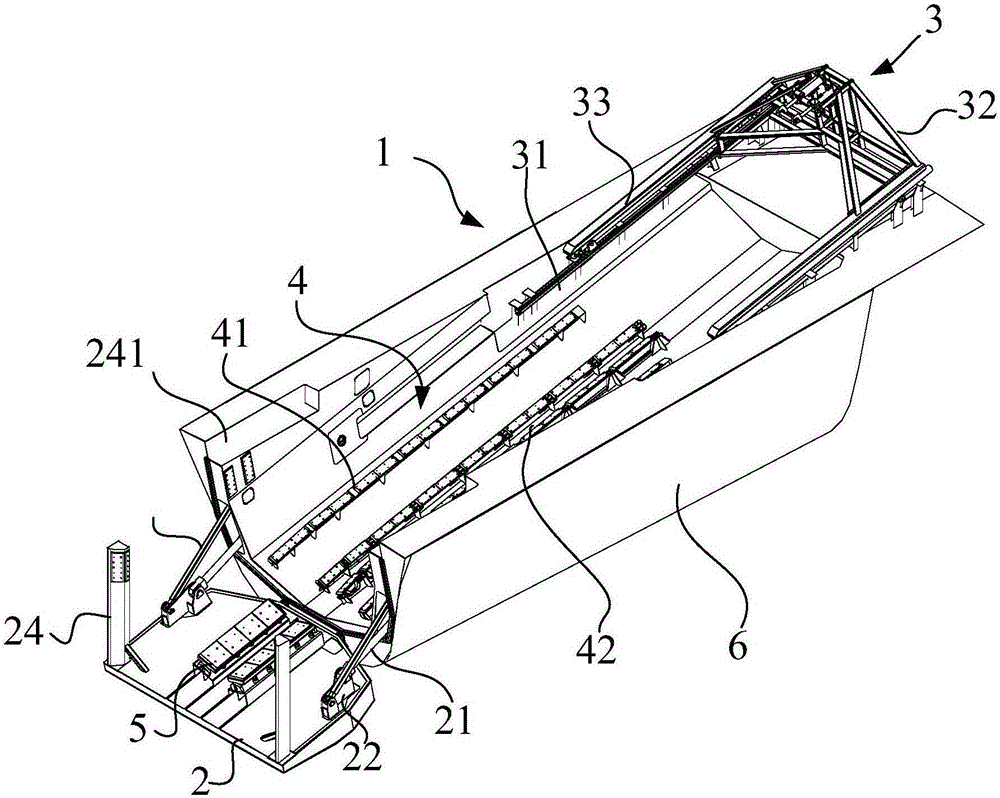

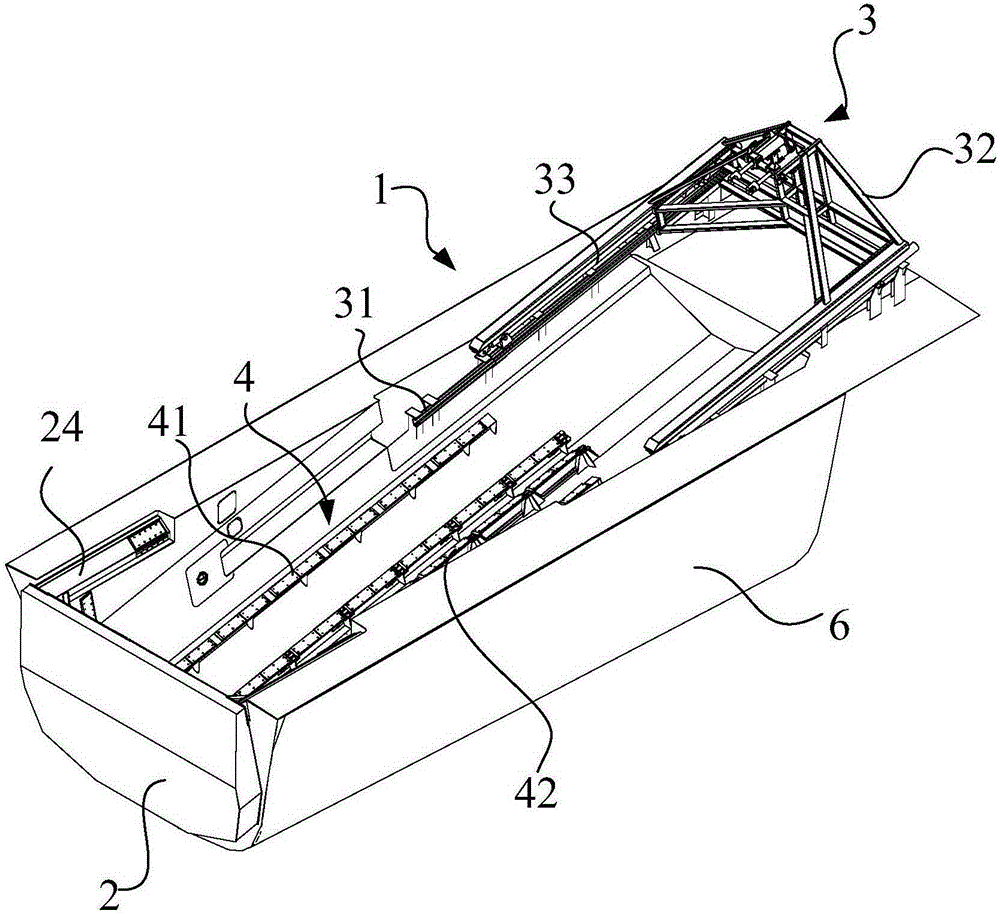

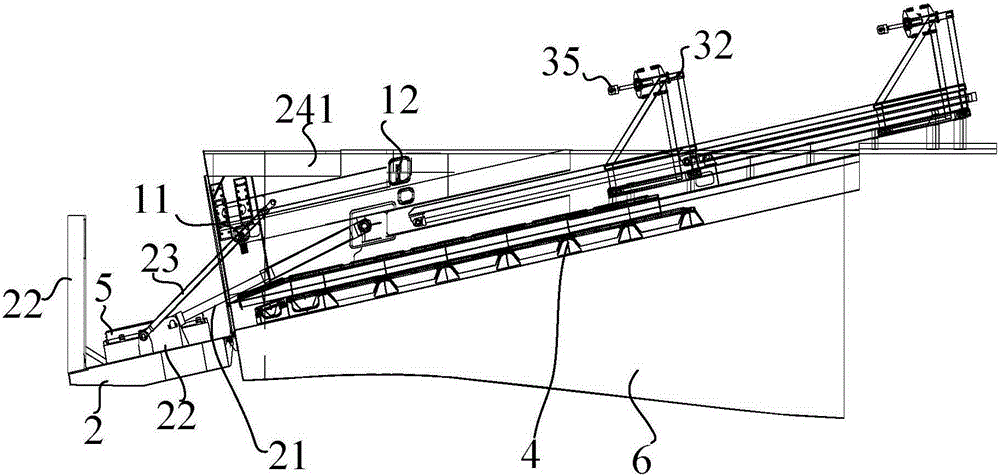

[0036] Example 1, such as figure 1 , figure 2 , image 3 As shown, this embodiment provides a stern slide type working boat retracting device, which includes a groove 1 arranged obliquely downward on the stern of the hull. The shape of the groove 1 is mainly designed according to the line type of the working boat. In the embodiment, the side wall of the groove 1 is composed of two parts, one part is a vertical downward side wall, another part is an inclined downward side wall, and between the two side walls is a channel of the groove 1. , The width of the channel of the groove 1 is much smaller than the width of the opening of the groove 1, and the line type of the general working boat is also a shape with a wide upper and a narrow bottom. Therefore, the shape of the groove 1 is generally based on the specific working boat. Therefore, the scope of protection of the present invention is not limited to the shape provided by the embodiment of the present invention. The stern door ...

Embodiment 2

[0053] Embodiment 2. This embodiment provides another stern slide type working boat retractable device.

[0054] Considering that 1 to 2 working boats generally need to be placed on the mother ship, in this embodiment, according to real-time requirements, such as Picture 10 , Picture 11 As shown, the difference between this embodiment and embodiment 1 is that two grooves 1 are arranged side by side on the stern part of the hull, and the side walls of the two grooves 1 on the side of the hull are much higher than the two grooves. 1 Adjacent side walls, the height of which is the height of the side walls of the vertical part described in embodiment 1, and the position where two grooves 1 are adjacent to each other, and the guide rail 31 is set on the side wall of groove 1 Above. Of course, two sets of traction devices 3 and two sets of traction slide assembly 4 are also provided. Two sets of stern door slides 5 are set on the stern door 4, and three guides are set on the stern d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com