Clamping device for special-shaped pipe welding

A technology of clamping device and special-shaped pipe, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient welding operation, low welding assembly efficiency, welding error, etc., so as to improve welding assembly efficiency and welding quality. , The effect of reducing welding error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

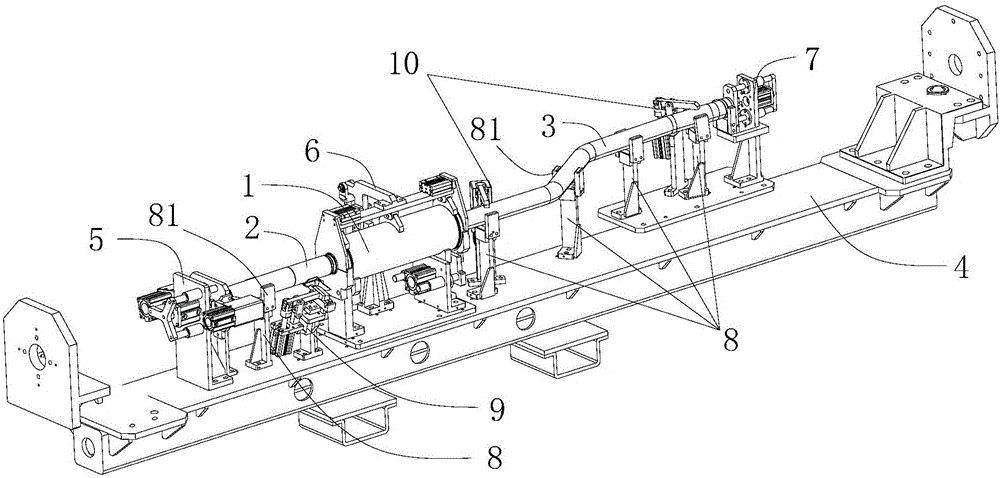

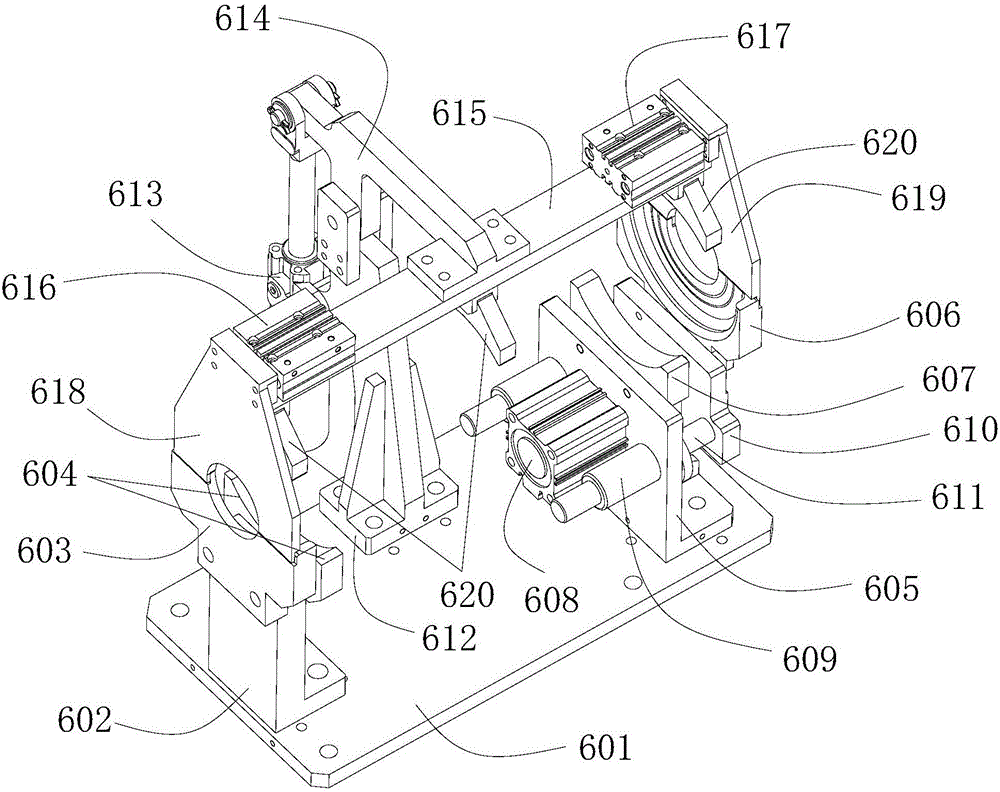

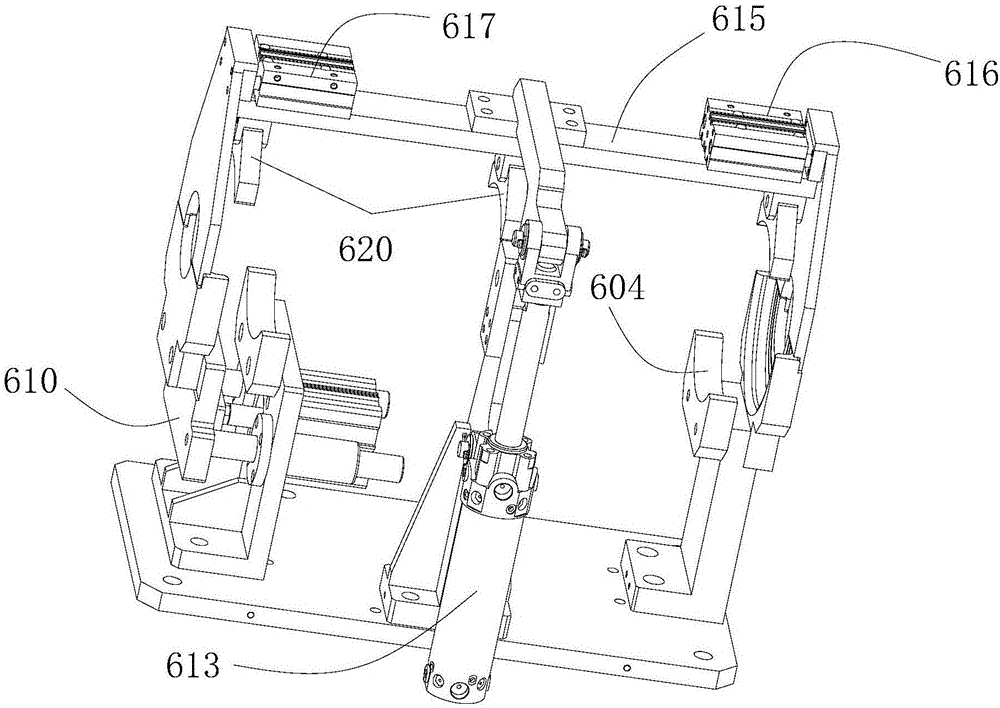

[0024] refer to Figure 1 to Figure 7 , is a clamping device for special-shaped pipe welding, which is used to clamp an automobile muffler. The automobile muffler includes a muffler body 1, a first exhaust pipe 2 and a second exhaust pipe 3; the first exhaust pipe 2 and the second exhaust pipe The second exhaust pipe 3 is connected to both ends of the muffler body 1 respectively, and the connection is the fixed end of the two exhaust pipes. The end of the first exhaust pipe 2 and the second exhaust pipe 3 located outside the muffler body 1 is free. end, the clamping device for special-shaped pipe welding includes a working platform 4, on which is provided a first clamping mechanism 5 for clamping the free end of the first exhaust pipe 2, a second clamping mechanism 5 for clamping and fixing the muffler body 1 Clamping mechanism 6, the third clamping mechanism 7 for clamping the free end of the second exhaust pipe 3, the clamping groove 8, the fourth clamping mechanism 9 for cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com