Light emitter

A technology of light-emitting elements and light-emitting parts, applied in optical elements, organic light-emitting devices, electrical components, etc., can solve the problem of difficulty in fully ensuring the light-emitting area of the hemispherical lens surface, and achieve high contrast, excellent weather resistance and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

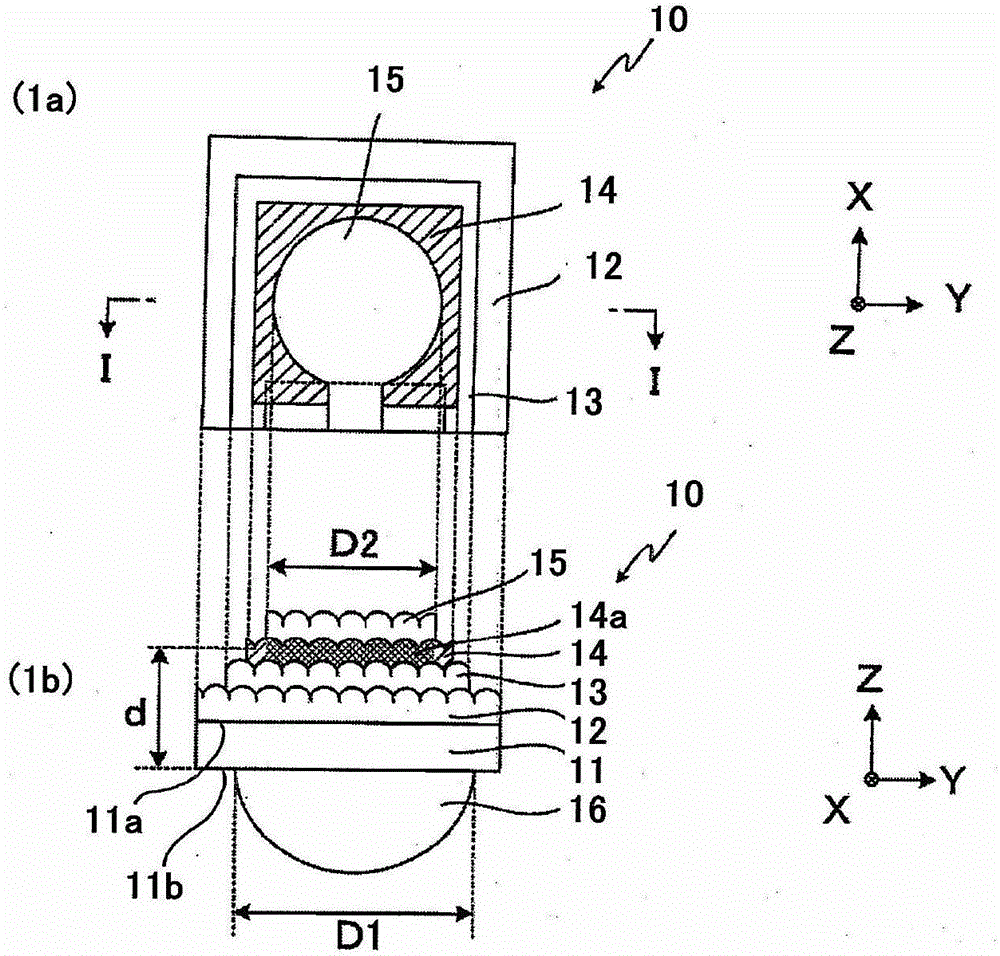

Embodiment 1

[0206] Toluene was added and dissolved in 230 mg of BCP manufactured by Polymer Source and 57.5 mg of polyethylene glycol 2050 manufactured by Aldrich as polyethylene oxide (number average molecular weight (Mn) = 2050) to make the total amount 15 g. , and then filtered through a membrane filter with a pore size of 0.5 μm to obtain a BCP solution.

[0207] The BCP used will be described below.

[0208] BCP is composed of PS-PMMA segments, the Mn of PS segment is 680000, the Mn of PMMA segment is 580000, the Mn of BCP is 1260000, the volume ratio of PS segment to PMMA segment is 57:43, and the molecular weight distribution The (Mw / Mn) was 1.28, the glass transition temperature (Tg) of the PS segment was 107°C, and the Tg of the PMMA segment was 134°C.

[0209] The volume ratio of the PS segment and the PMMA segment is that the density of PS is 1.05g / cm 3 , The density of PMMA is 1.19g / cm 3computational. The Mn and Mw are measured using gel permeation chromatography columns i...

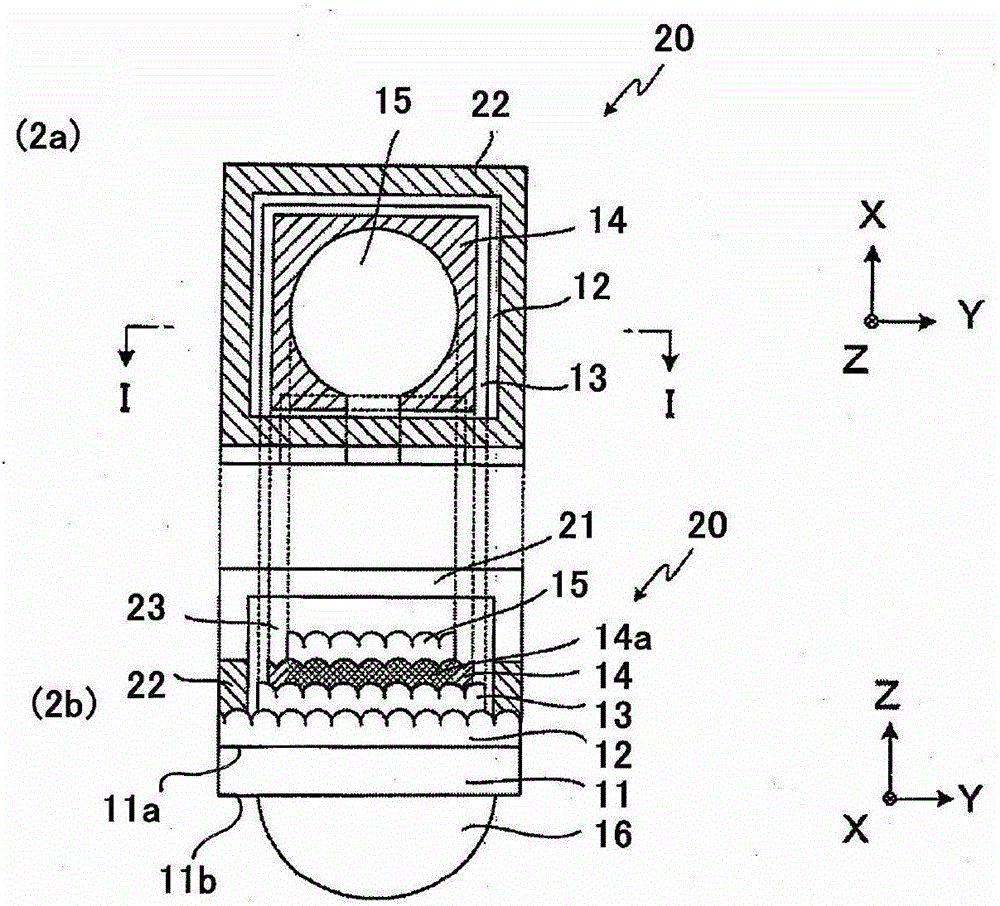

Embodiment 2

[0245] A light-emitting element was produced in the same manner as in Example 1, except that the masks used for the patterns of the transparent electrode layer and the metal electrode layer were changed, and the diameter D2 of the light-emitting portion was changed to 9.0 mm. r1 of the obtained light-emitting device was 0.90, and r2 was 0.07. In addition, the light emitting area was measured in the same manner as in Example 1. The results are shown in Table 1 and Figure 6 (6b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average spacing | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com