Sleeve seal for electric furnace electrodes

A technology of sealing components and sealing components, which is applied to the sealing of engines, electric furnace heating, furnace components, etc., and can solve the problems of not being able to adapt to significant changes in electrode diameter, high cost, difficult inspection and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In the description below, specific details are set forth in order to provide examples of claimed subject matter. However, the embodiments described below are not intended to define or limit the claimed subject matter. Those skilled in the art will recognize the many variations that are possible in specific embodiments within the scope of the claimed subject matter.

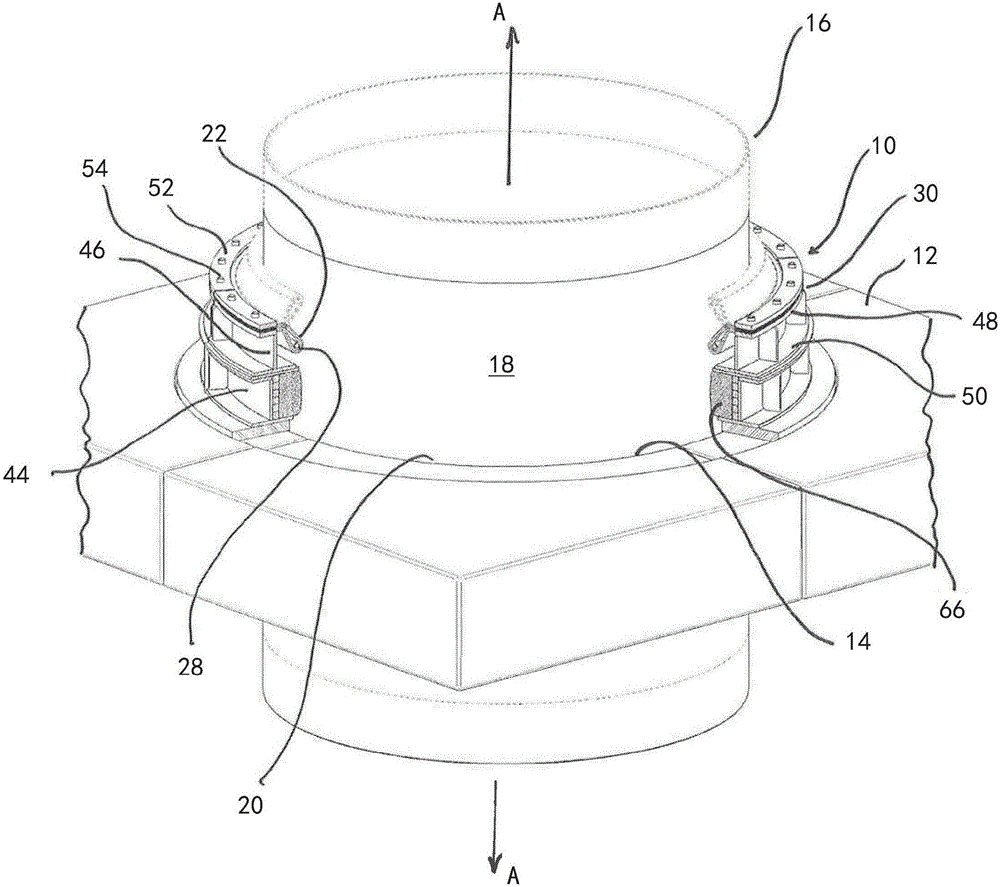

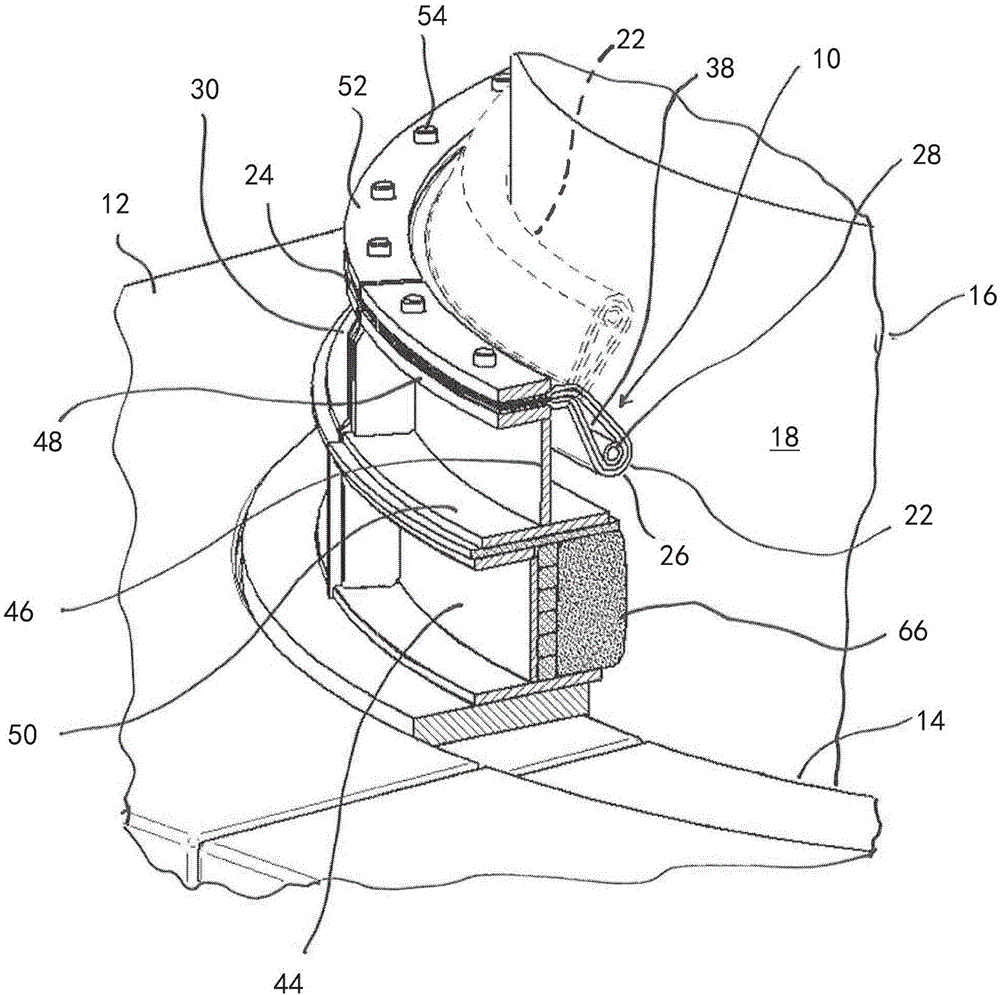

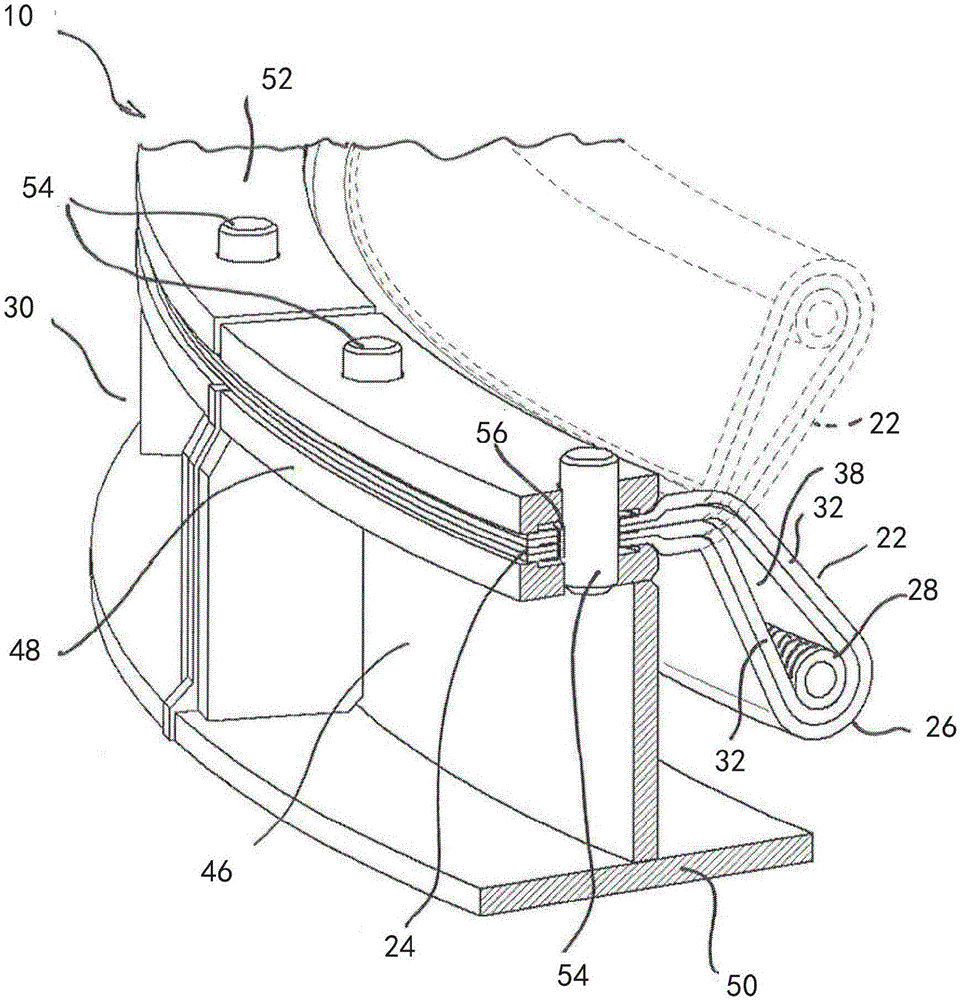

[0041] The first embodiment described below relates to a seal for sealing an electrode port in an electric furnace roof through which a vertically oriented electrode extends. It should be appreciated, however, that the seals described below may be applicable in other fields where sealing against substantially varying cylindrical surfaces is required and where there is relative movement between the seal and the cylindrical surface. It should also be appreciated that the surfaces are not necessarily cylindrical, nor are they necessarily vertical. However, the seals described below can be used with devices h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com