Expandable high-strength steel material and expanded high-strength steel pipe having excellent expansibility and crush strength, and manufacturing method thereof

A high-strength, expansive technology, applied in the field of high-strength steel and expansive high-strength steel pipe, high-strength steel pipe manufacturing, can solve the problems of low expansiveness, application limitations, difficulty in obtaining strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The inventors conducted research on methods for solving the problems of existing expandable steel materials, and obtained the following knowledge. High manganese steel, which is an austenitic steel material, has a high level of uniform elongation, and thus high manganese steel has high expansibility. However, the stability of austenite in the negative segregation zone of high manganese steel is low due to the alloy composition difference between the negative segregation zone and the positive segregation zone. Therefore, if the austenite formed in the negative segregation region is deformed due to expansion, and thus transformed into martensite, many dislocations are formed, and this dislocation weakens the Bauschinger effect. Based on these findings, the inventors have invented the present invention.

[0019] Exemplary embodiments of the present invention will now be described.

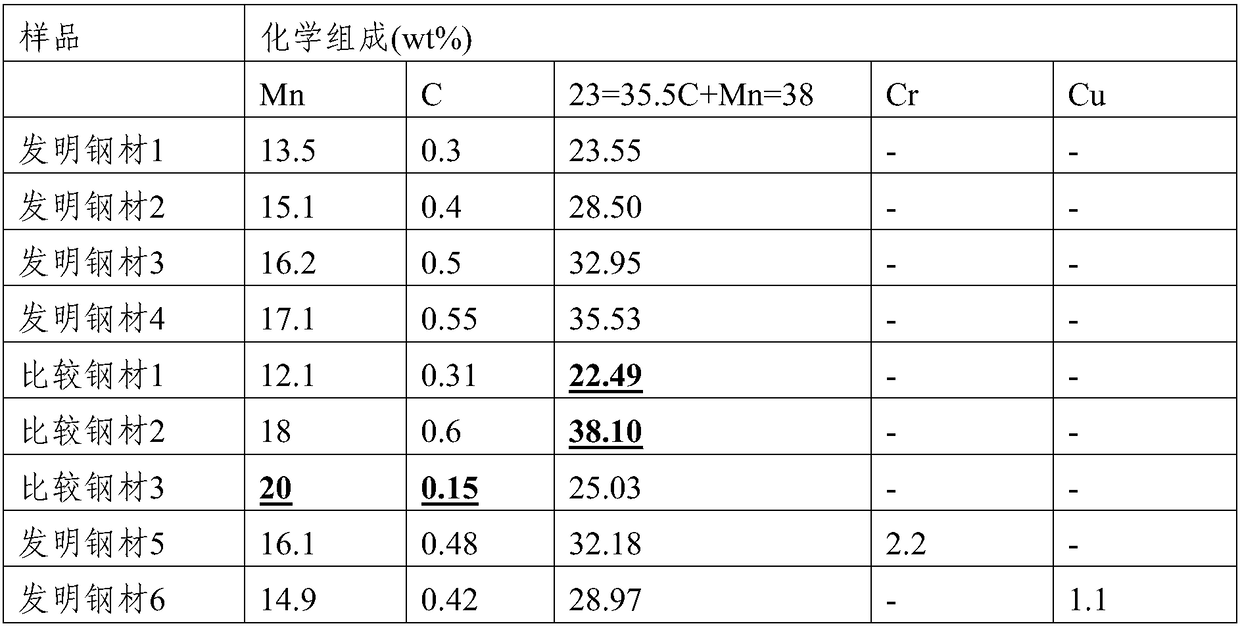

[0020] Manganese (Mn): 12wt% to 18wt%.

[0021] As a representative element for stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com