Heat dissipation structure of electronic equipment

A technology of heat dissipation structure and electronic equipment, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., which can solve the problems of poor heat dissipation effect and complex heat dissipation structure, and achieve simplified structure, good heat dissipation effect, and avoid heat generation serious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

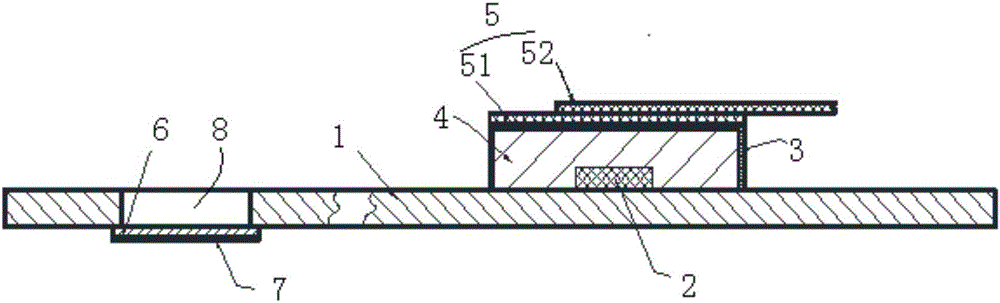

[0027] Such as figure 1 As shown, the electronic equipment in this embodiment is a mobile phone component, including an insulating base plate 1 (PCB board in this embodiment), heating components 2 (CPU in this embodiment) and a heat dissipation structure. The heat dissipation structure includes a shield cover 3 , a heat conduction component 4 , a heat dissipation component 5 , a baffle plate 6 and a heat insulation component 7 . Wherein, the shielding cover 3 independently covers the heating components 2 arranged on the insulating base plate 1; Between the inner top wall of the shield 3, fill the gap between the heating element 2 and the shield 3; the heat dissipation component 5 includes a first heat dissipation element that covers the upper surface of the shield 3 51, and a second heat sink 52 that covers part of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com