A vertical structure root-enhanced field-effect transistor and its manufacturing method

A field-effect transistor and vertical structure technology, which is applied in the vertical structure GaN-based enhancement field-effect transistor and its manufacturing field, can solve the problems of device surface breakdown reduction, few research reports, breakdown voltage increase, etc., to increase output current , Improving the withstand voltage capability and facilitating packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

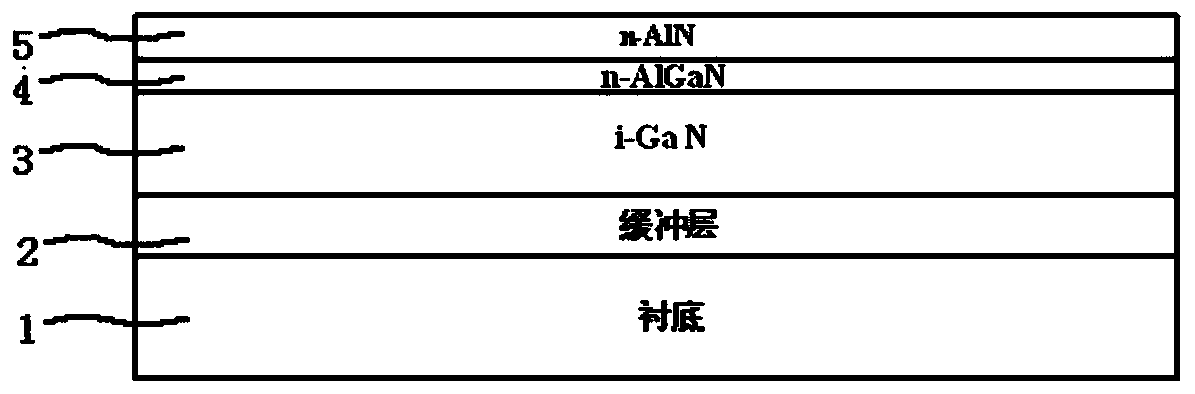

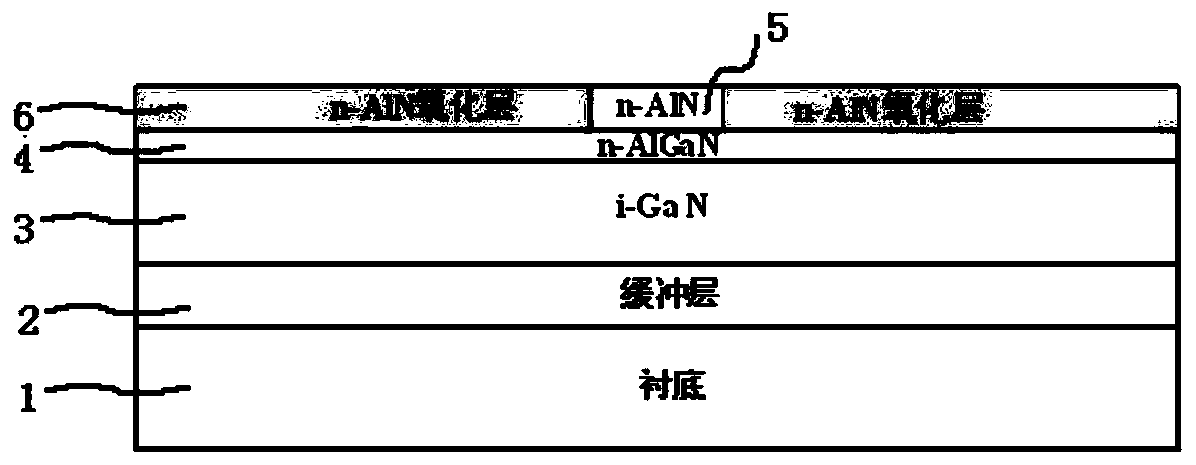

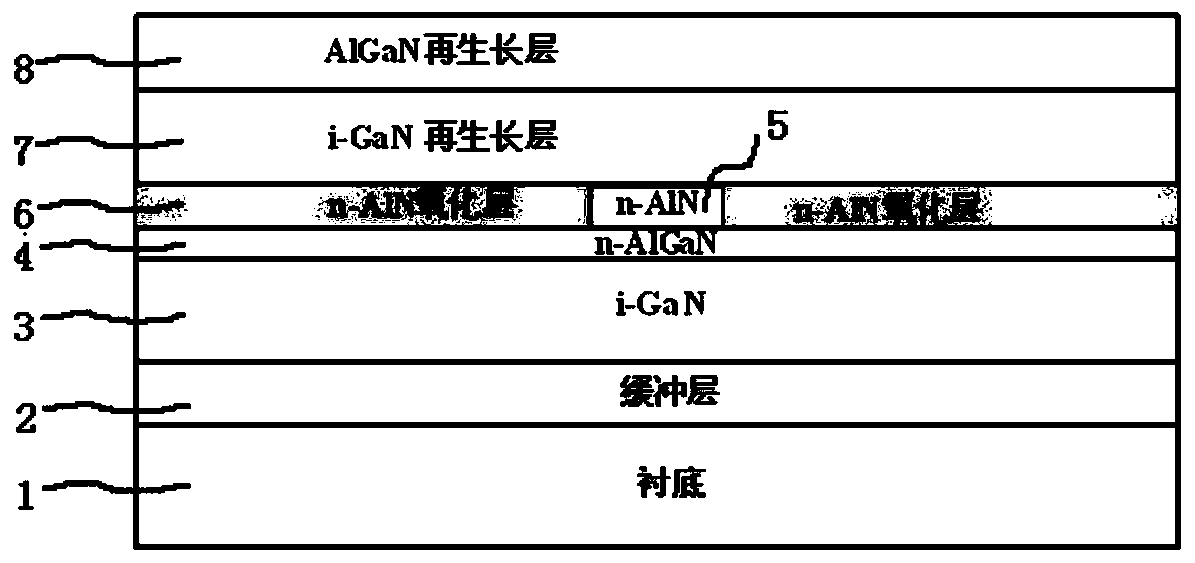

[0031] FIG. 1( h ) is a schematic diagram of the device structure of Example 1. Its structure includes substrate layer (1), buffer layer (2), unintentionally doped GaN (i-GaN) epitaxial layer (3), n-type AlGaN (n-AlGaN) epitaxial layer (4), n-type AlN (n -AlN) conductive layer (5) and n-AlN oxide layer (6), i-GaN regrowth layer (7), AlGaN regrowth layer (8), gate oxide layer (9), arranged on (8) The source (10), the drain (11) arranged on (4), and the gate (12) arranged on (9).

[0032] The manufacturing process flow of the above-mentioned vertical structure GaN-based enhancement mode field effect transistor is as follows:

[0033] A) As shown in Figure 1(a), a buffer layer (2), an i-GaN epitaxial layer (3), and an n-AlGaN layer are sequentially grown on a substrate (1) by metal-organic chemical vapor deposition (MOCVD) (4), n-AlN layer (5), the epitaxial growth temperature is between 1050°C and 1100°C, the substrate (1) is one of sapphire, silicon, silicon carbide or galliu...

Embodiment 2

[0042] like figure 2 It is a schematic diagram of the device structure of Example 2. It is similar to the device structure of Example 1, the only difference is that in step C of the manufacturing process flow, a secondary epitaxial growth containing i-GaN layer (7) and no + - Homojunction formed by GaN layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com