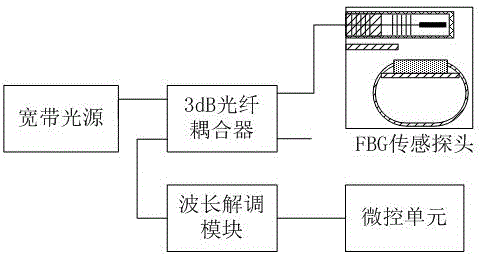

Discontinuous liquid level sensor based on optical fiber bragg grating technology

A liquid level sensor, discontinuous technology, applied in the direction of buoy liquid level indicator, etc., can solve the problem of increased workload, and achieve the effect of small size, low power consumption and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

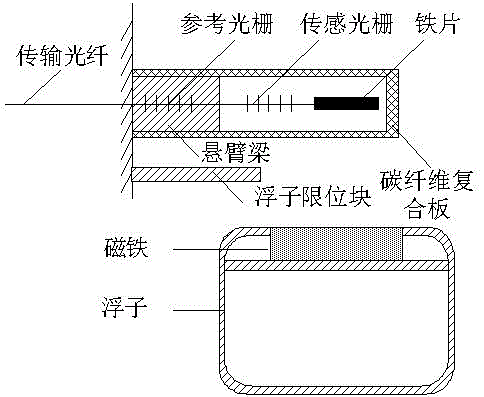

[0020] The Bragg equation of fiber grating is λ= 2 n eff Λ, the central reflection wavelength λ of the fiber Bragg grating will vary with the grating period Λ and the core effective refractive index n eff change with changes. When the FBG is subjected to a longitudinal strain or the surrounding temperature changes, Λ and n eff will change, causing the grating Bragg center wavelength to shift by dλ=2 n eff dΛ+2Λdn eff .

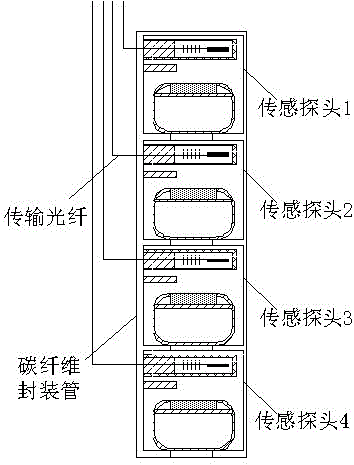

[0021] The structure of the FBG sensing probe used for liquid level detection in a non-continuous liquid level sensor based on fiber Bragg grating technology is as follows: figure 2 As shown, a schematic diagram of a float with a magnet installed inside and a schematic diagram of a FBG sensor placed in a package are shown. The FBG sensor is composed of a fiber Bragg grating cantilever beam structure. When the liquid level rises, the float also moves upward. At this time, the magnet in the float attracts the carbon fiber plate with the iron sheet. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com