A roller kiln partition broken roller detection method and system

A detection system, roller kiln technology, applied in furnace types, furnaces, charging processing types, etc., can solve the problems of inability to achieve overall monitoring of multiple areas, inability to monitor rollers, and low monitoring efficiency, and to extend reliable working time. , The effect of overcoming temperature sensitivity and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

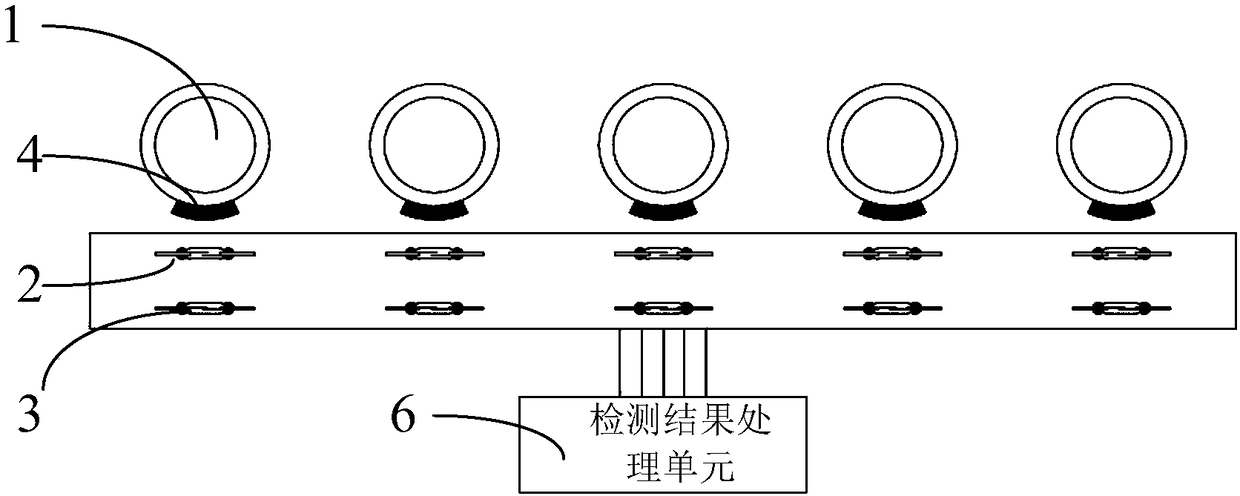

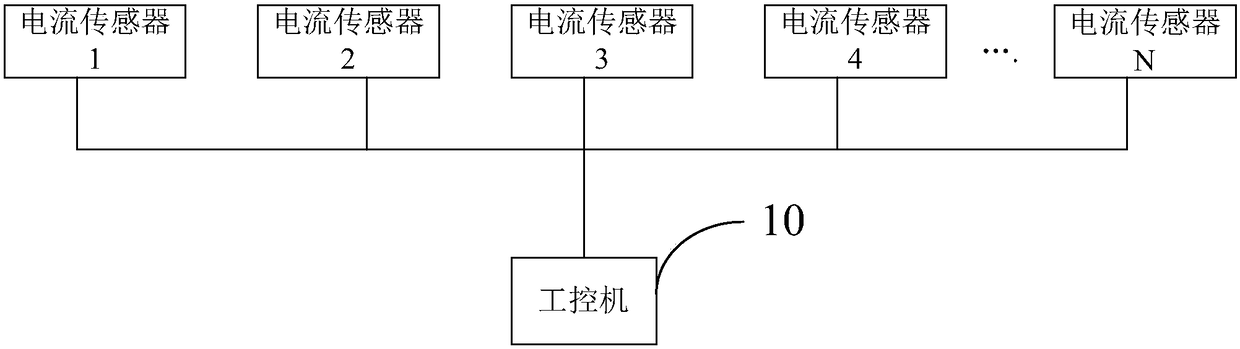

[0032] The embodiment of the present invention firstly discloses a roller kiln zone broken roller detection system, including:

[0033] The follower element corresponding to each roller bar is arranged on the driven side of the roll bar, and two induction switches are respectively arranged in the sensing area under each driven side that can sense the follower element, which are respectively recorded as the first induction switch. switch and a second sensor switch.

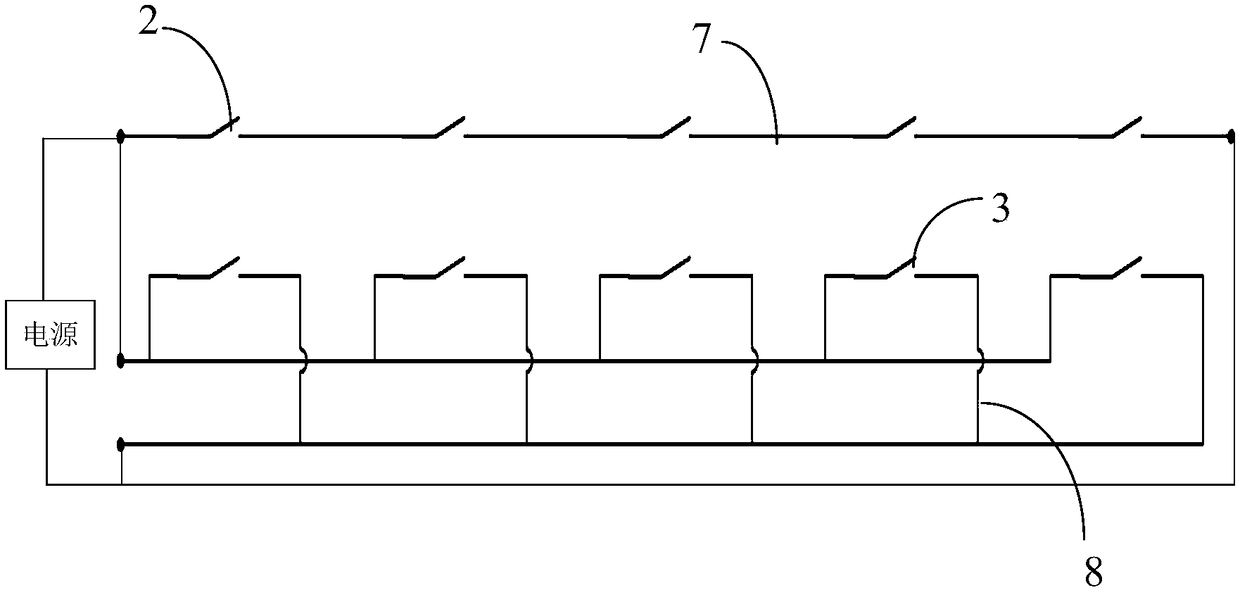

[0034] A series circuit, in which all the first induction switches in any partition are connected in series.

[0035] The parallel circuit has all the second inductive switches in any partition connected in parallel.

[0036] The detection result processing unit is used to simultaneously detect whether the on-off of the series circuit and the parallel circuit changes periodically after the corresponding partition is started. It is judged that the partition is broken.

[0037] Wherein, in a normal state before th...

Embodiment 2

[0050] Corresponding to the above-mentioned embodiment 1, this embodiment discloses a method for detecting broken rollers in a roller kiln zone, such as Figure 9 shown, including:

[0051] Step S1, setting two induction switches respectively in the induction area capable of inducting the follower element under the driven side of any roller, which are respectively denoted as the first induction switch and the second induction switch. Wherein, in a normal state before the start of any partition roller bar, the relative positional relationship between each follower element and the corresponding first and second induction switches is consistent.

[0052] Step S2, building a series circuit to connect all the first induction switches in the partition in series, and building a parallel circuit to connect all the second induction switches in the partition in parallel.

[0053] Step S3: Simultaneously detect whether the on-off of the series circuit and the parallel circuit is periodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com