Electromagnetic active and passive integrated vibration isolator

An electromagnetic actuator and vibration isolator technology, applied in the direction of non-rotational vibration suppression, can solve the problems of large space occupation, poor robustness, limited actuator output force, etc., and achieve high space utilization and reliability and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described in detail in conjunction with the accompanying drawings.

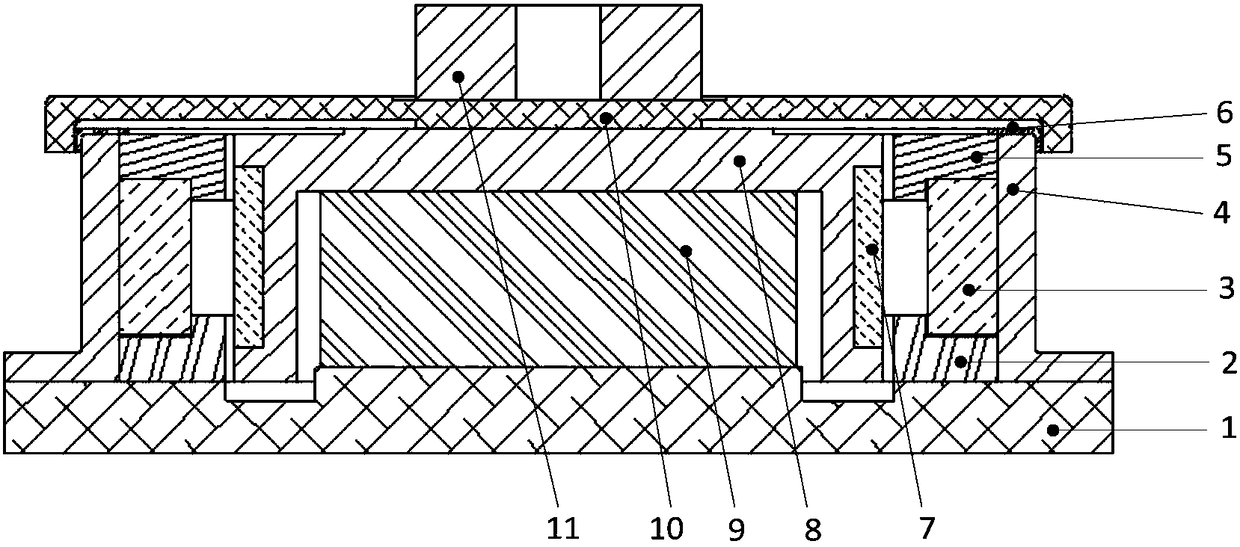

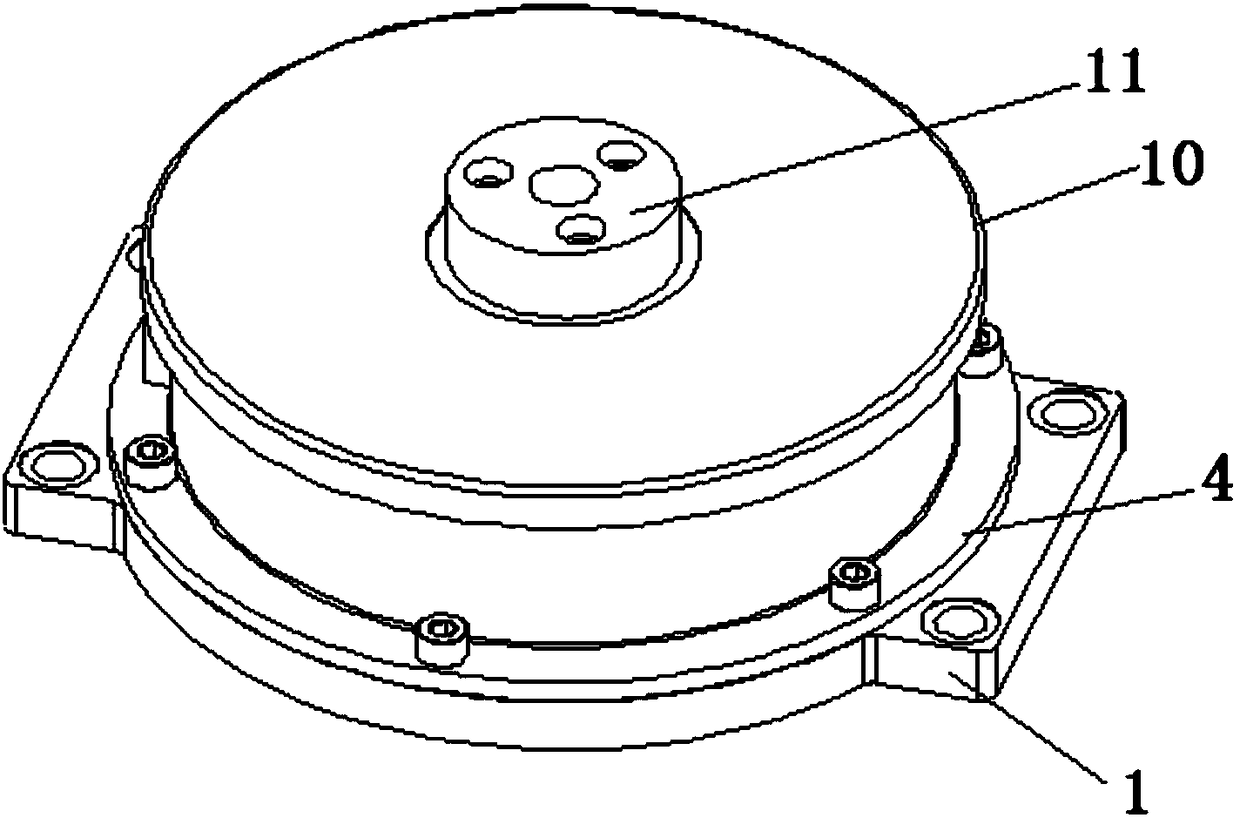

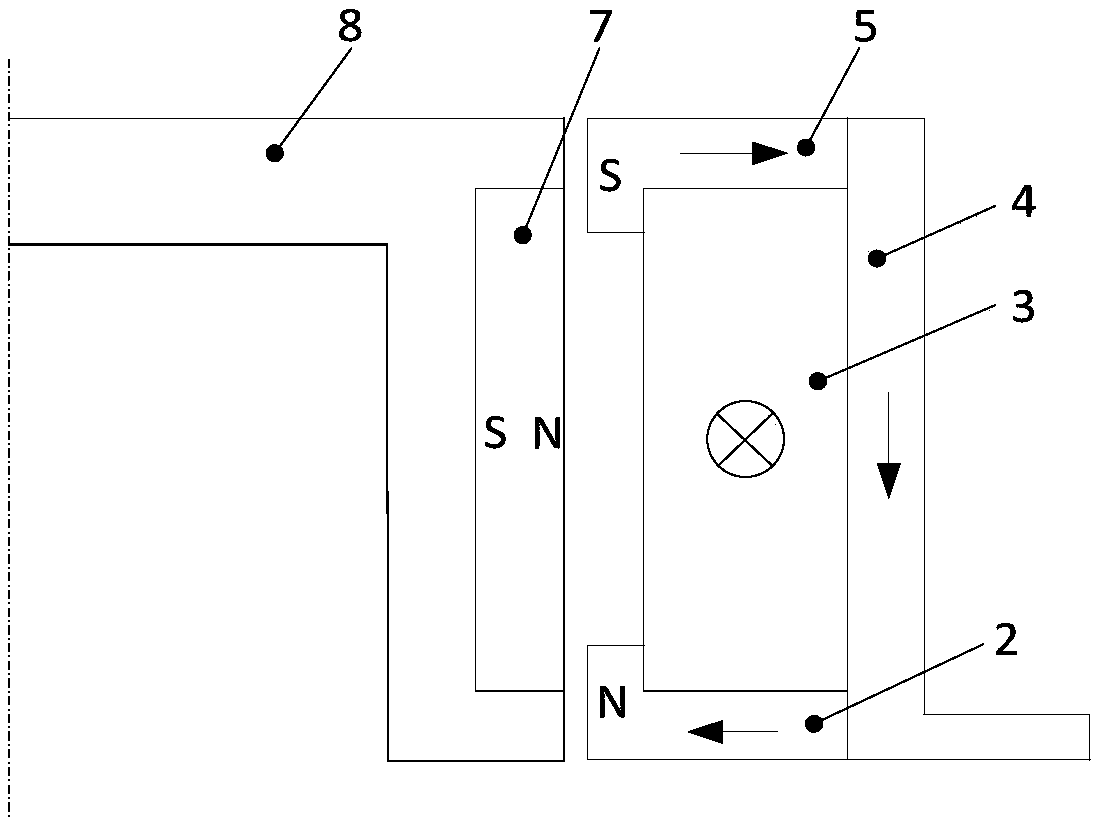

[0025] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes a passive vibration isolator 9, an electromagnetic actuator, a safety cover 10, a rubber pad 6, an actuator base 1, and an equipment connector 11. The electromagnetic actuator is composed of an actuator stator, The actuator mover is composed of the actuator mover. The actuator mover is installed inside the actuator stator and is coaxial. The actuator stator is composed of a coil 3, a stator frame 4, a stator lower end cover 2, and a stator upper end cover 5. The coil 3 and the stator The skeleton 4, the stator lower end cover 2, and the stator upper end cover 5 are bonded together by AB glue to form a whole. The actuator mover is composed of a permanent magnet 7 and a mover yoke 8. The cylindrical permanent magnet magnetized by radiation is not easy to manufacture , the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com