Spherical roller bearing and wind turbine main shaft transmission chain system comprising same

A technology of spherical roller bearing and bearing inner ring, which is applied in the field of bearings to avoid excessive load on one side and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

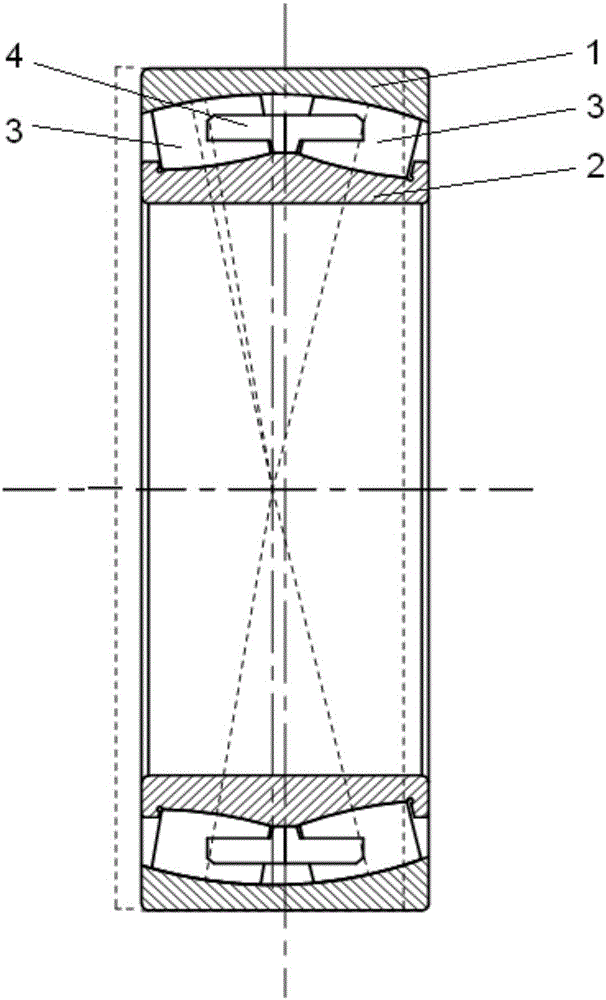

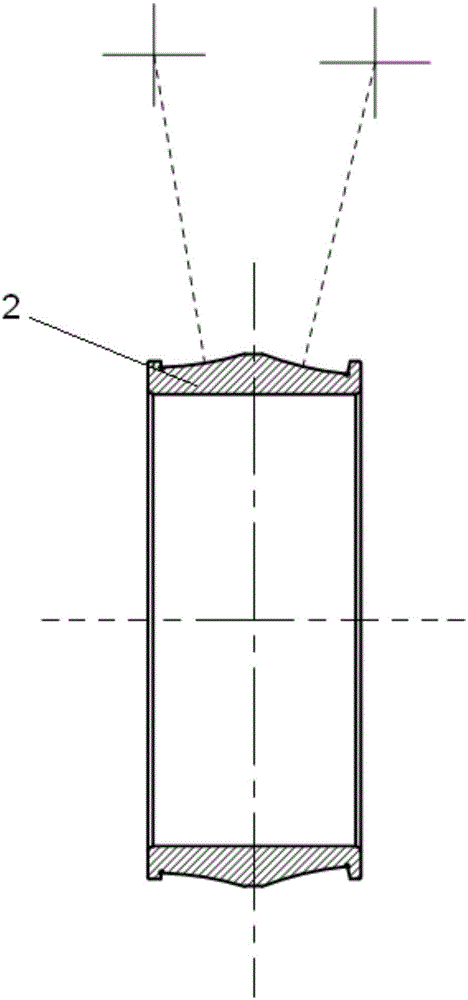

[0020] Refer to attached figure 1 As shown, the spherical roller bearing of the present invention includes a bearing outer ring 1, a bearing inner ring 2, a cage 4 arranged between the bearing outer ring 1 and the bearing inner ring 2 and having two rows of pockets, and a cage 4 arranged on the cage 4 The spherical roller 3 in the pocket.

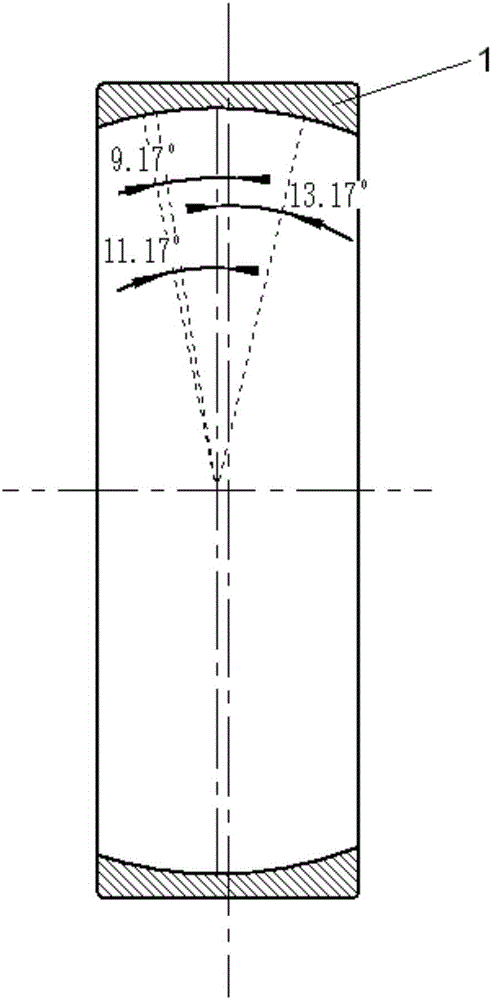

[0021] In the present invention, the inner side of the bearing outer ring 1 is provided with an asymmetric spherical raceway, and a preferred embodiment is that the spherical raceway is an arc-shaped spherical surface whose center of the sphere does not coincide with the center of the bearing. Certainly, the asymmetrical spherical surface may also be formed by connecting arc-shaped spherical surfaces with two centers of different curvatures.

[0022] In this embodiment, the existing symmetrical spherical raceway is rotated to one side by a small angle around the center of the sphere, and then the overall structure of the bearing is shifted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com