Simulate five-spot network micro carve visualization model and apply method

A five-point well pattern and microcosmic technology, applied in the direction of earthwork drilling, wellbore/well components, and production fluid, can solve the problems of accuracy discount, cost waste, and inability to completely clean the fluid, and achieve simple and easy disassembly. Assemble, easy to place and observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation.

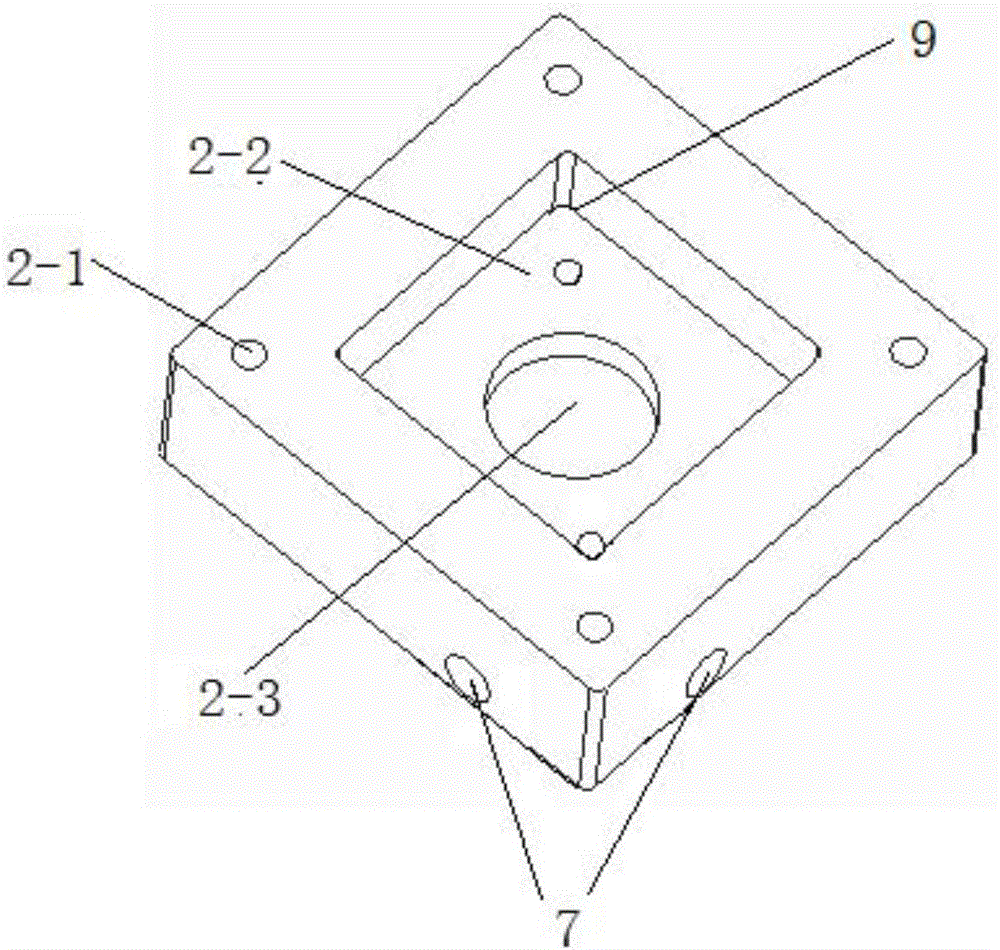

[0030] Such as Figure 1 to Figure 7 As shown, a visual model of microscopic etching for simulating a five-point well pattern, including a focusing cover 1, a base 2, a base sealing film 6, an etching glass piece 5, an observation glass piece 4, a focusing cover sealing film 3, and bolts; The base 2 is aligned with the focusing cover 1 and connected by bolts. The focusing cover 1 is a square structure with four through holes 1-1 on the four sides. The upper end of the through holes 1-1 is provided with a stepped hole with a diameter of approximately A nut that is larger than the connecting bolt; a section of square boss 1-2 is provided on the lower side of the middle part of the focusing cover 1, and the center of the boss 1-2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com