Stress test method for oil well casing

A technology of oil well casing and testing method, which is applied in the direction of construction, etc., can solve the problems that the in-situ stress test of shallow ultra-heavy oil reservoirs cannot be carried out, and achieve the effect of improving steam injection efficiency and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

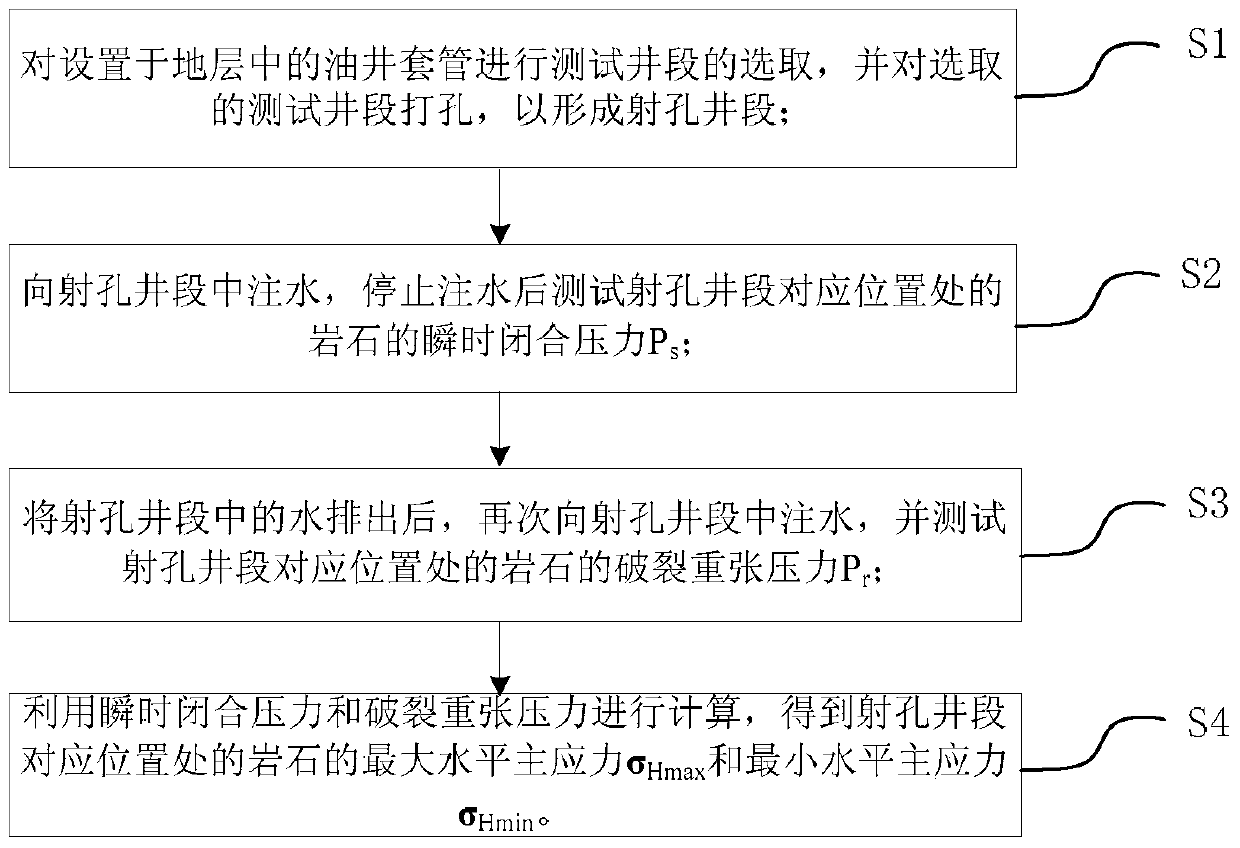

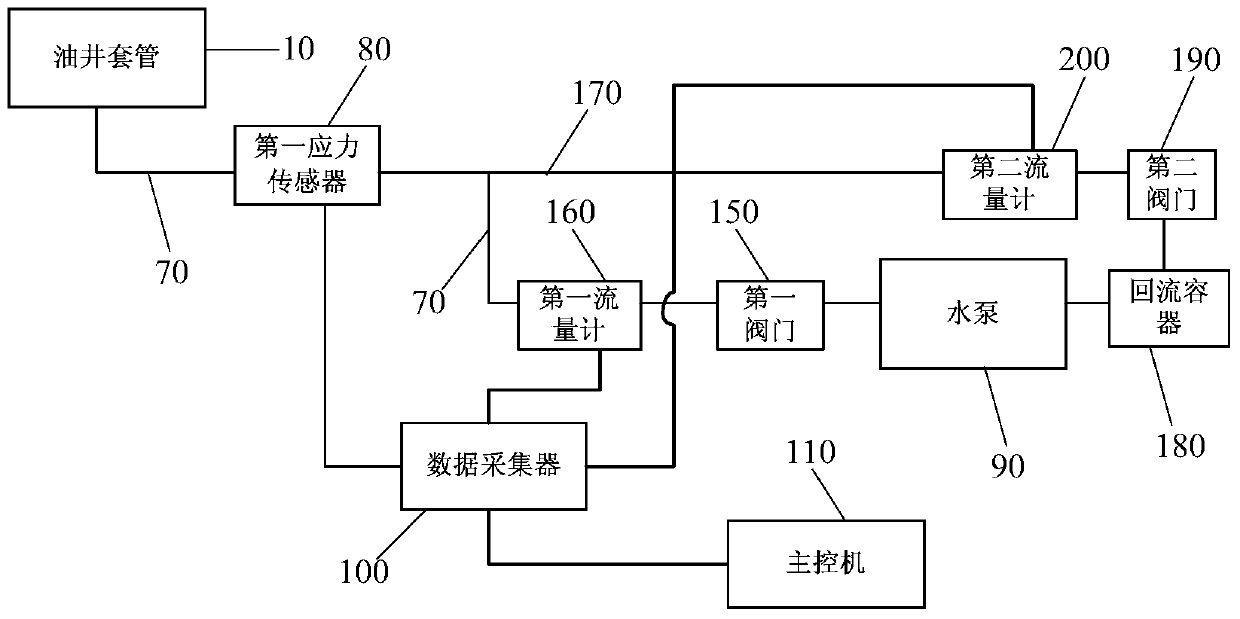

[0070] The stress testing method for oil well casing provided in this embodiment includes the following steps:

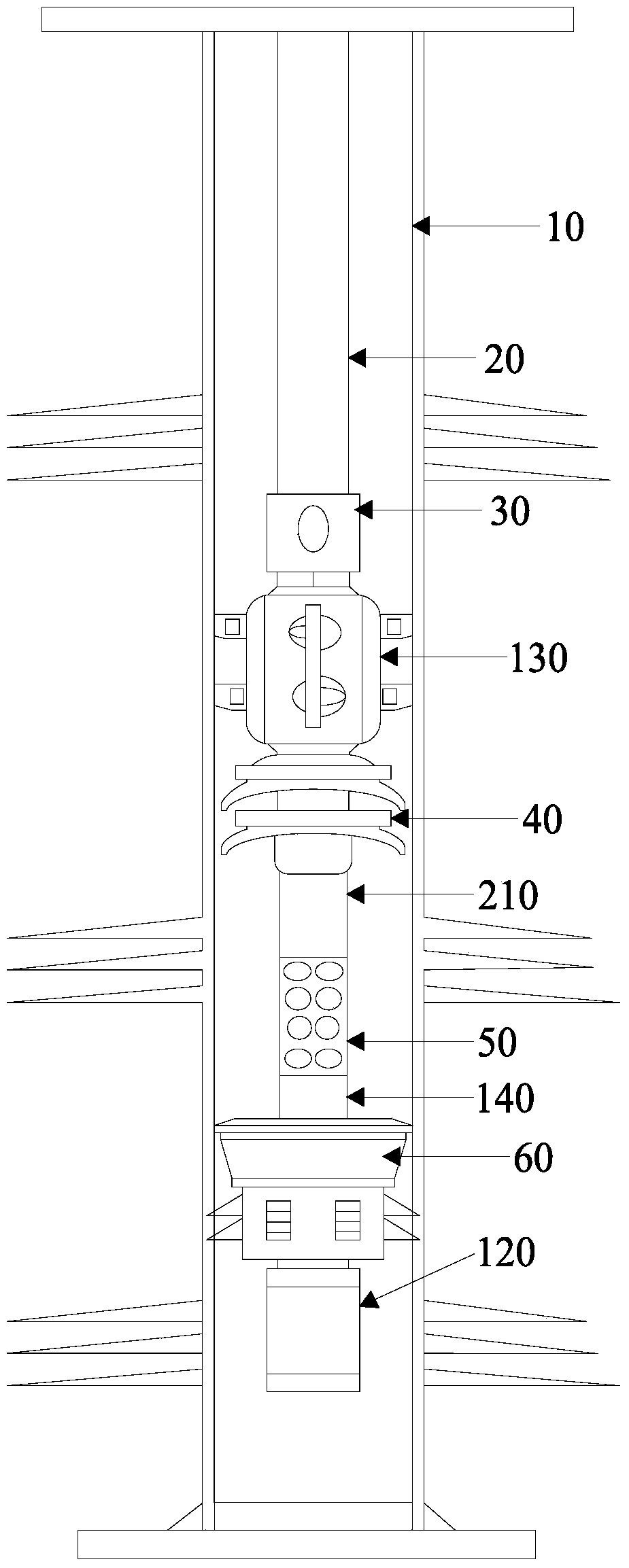

[0071] 1. Measure the in-situ stress of a vertical well F1 in the ultra-heavy oil block of Xinjiang Oilfield. The casing depth of the well is 100m. According to the core data and engineering design requirements of the core well in the block, the reservoir cap layer ( There are five test sections in total, oil layer (section 3), and bottom layer (section 1). Perforation is carried out at the corresponding oil well casing of these five test sections. YD-89 perforating bullet cable is used for perforation. The perforation density is 20 holes / m, and each perforation section is 0.5m.

[0072] 2. After the perforation is completed, use a Ф152mm×1000mm (diameter×length) gage to pass the well to the artificial bottom.

[0073] 3. Use a 177.8mm wall scraper to scrape the casing of the oil well to the bottom of the artificial well, and scrape the wall three times in the test sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com