Hydrostatic fishing device

A salvage device and static pressure technology, applied in wellbore/well components, earthwork drilling and other directions, can solve problems such as difficulty in salvaging well falling objects, restrictions on salvage objects, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

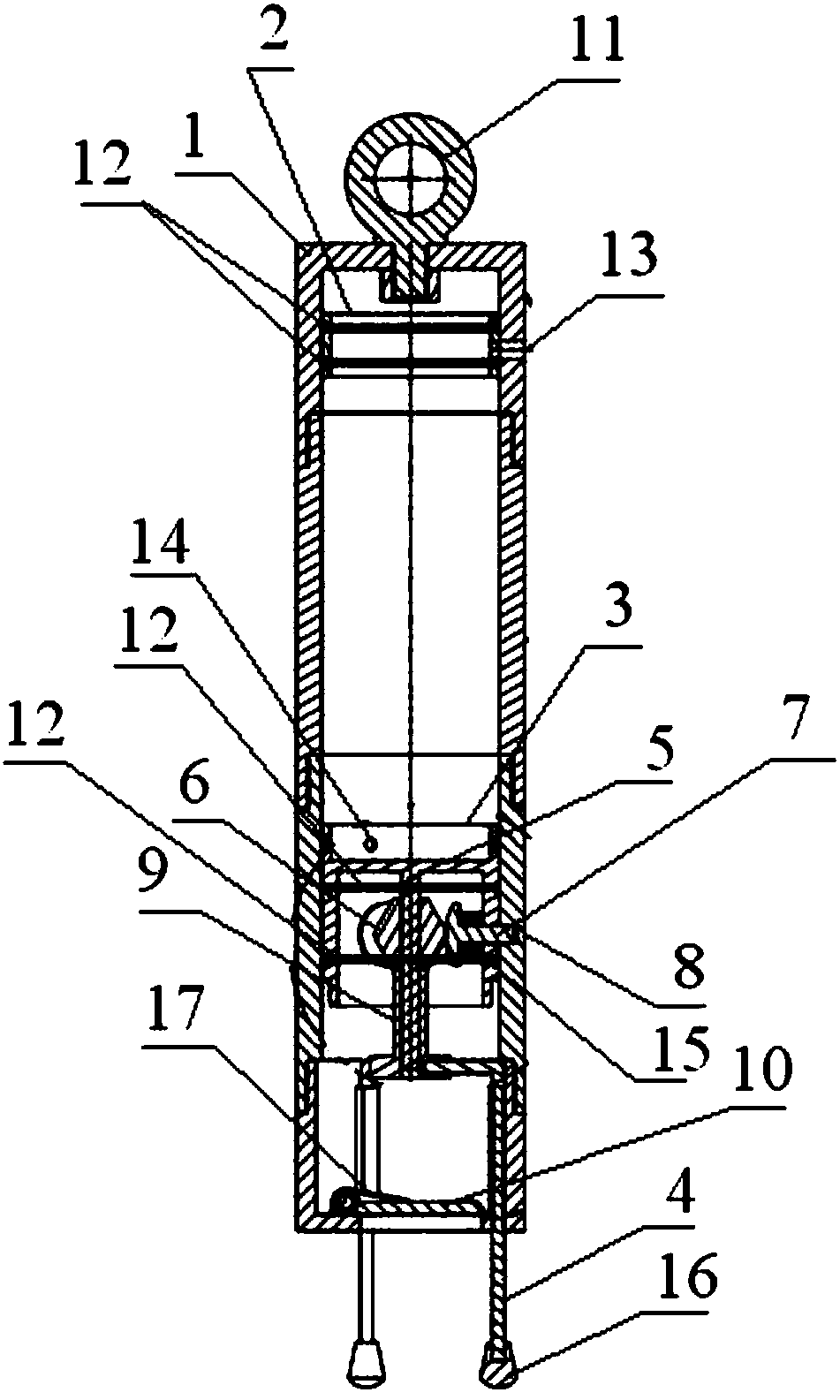

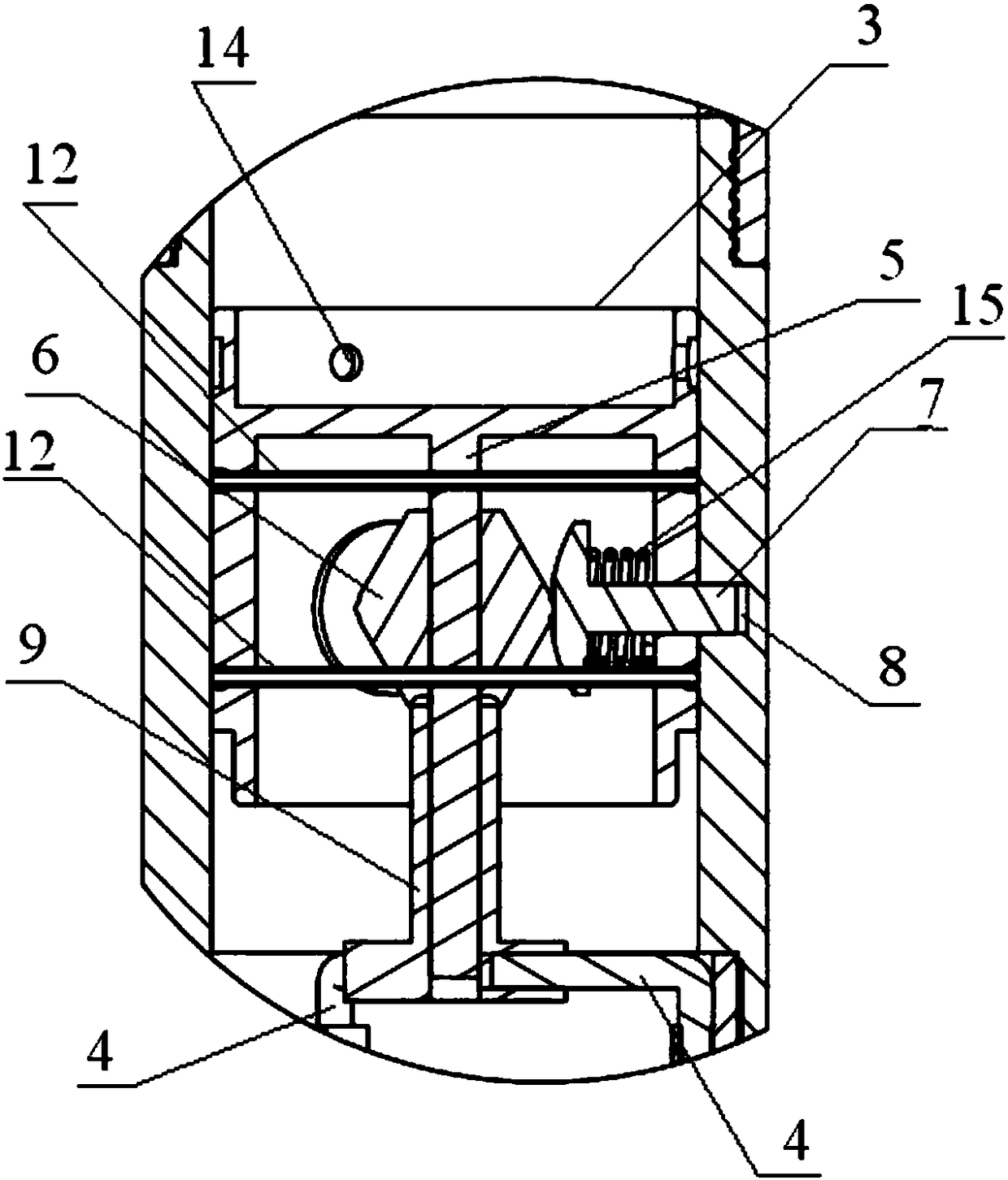

[0021] see figure 1 and figure 2 Shown:

[0022] The static pressure fishing device provided by the present invention includes an outer pipe 1, an upper slip ring 2, a lower slip ring 3 and a feeler rod 4, wherein the upper slip ring 2 is arranged on the upper part of the inner cavity of the outer pipe 1, and the lower slip ring 3 is arranged in the inner cavity of the outer pipe 1 The lower part of the sliding ring 3 is provided with a guide rod 5, the guide rod 5 is provided with a central cam 6, the central cam 6 can slide up and down along the guide rod 5, one side of the central cam 6 is engaged with a movable shaft 7, and the movable shaft The rear end of 7 is pierced in the installation hole 8 provided by the sliding ring 3 and the side wall of the outer tube 1, and the lower end of the guide rod 5 is equipped with a connector 9, which can slide up and down on the guide rod 5, and the connector 9 The upper end of the upper end can touch the lower end of the central c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com