Highly pressurized liquid driven eccentric sheave type bottom hole sleeve cutter

A technology of high-pressure liquid and eccentric wheel, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of unfavorable environmental protection and energy saving, complicated and cumbersome structure of casing cutter, and low efficiency of use, so as to save materials , simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

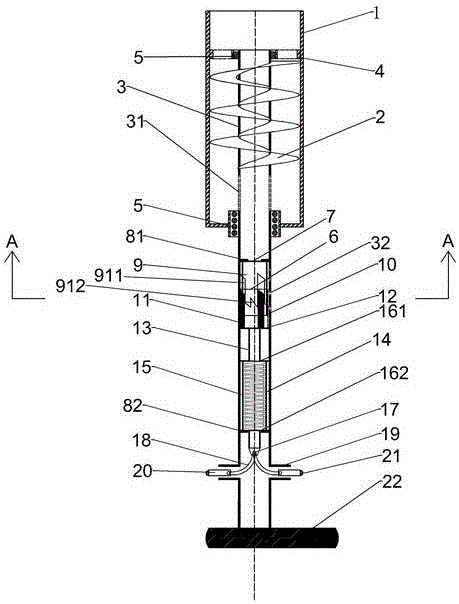

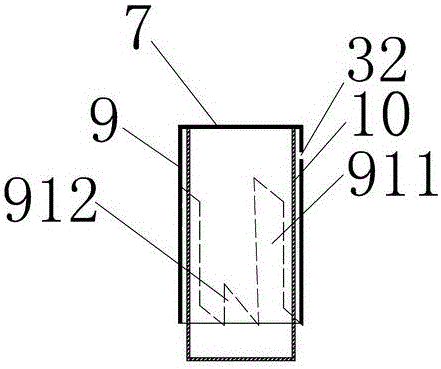

[0034] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, it is an embodiment of the present invention, including an upper cylinder body 1, a helical blade 2, a helical blade installation shaft 3, a helical blade limit seat 4, several balls 5, a lower cylinder sleeve 6, and an automatic rebound mechanism. Base 7, upper limit seat 81, lower limit seat 82, upper cylinder outer sleeve 9, upper cylinder inner sleeve 10, lower cylinder outer sliding column 11, automatic rebound mechanism lower base 12, connecting column 13, spring Centralizing cylinder 14, constant loose spring 15, spring upper base 161, spring lower base 162, pin 17, crank connecting rod 18, cutting tooth slideway 19, cutting tooth base 20, cutting tooth 21 and detachable eccentric wheel 22;

[0035] Wherein the screw blade 2 and the screw blade installation shaft 3 are all arranged in the upper cylinder body 1, the screw blade 2 is fixedly arranged on the screw blade installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com