Assembled civil air defense door and its modular door leaf

A modular, civil air defense door technology, applied in the direction of door leaves, windows/doors, sealing devices, etc., can solve the problems of cumbersome, complicated door leaf manufacturing process, difficult transportation, etc., to ensure positioning accuracy and reduce the risk of over-width and over-length transportation coefficient, the effect of facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

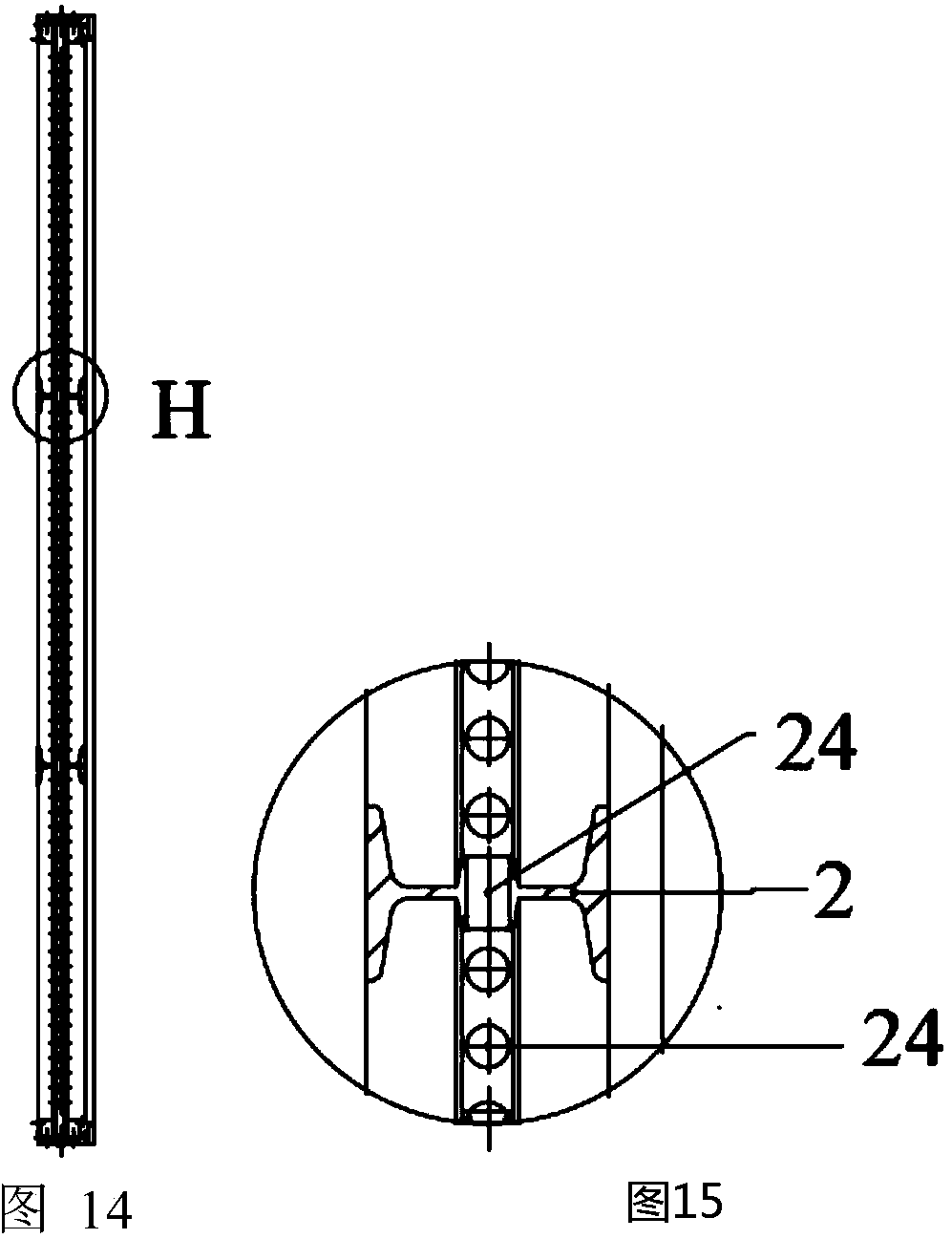

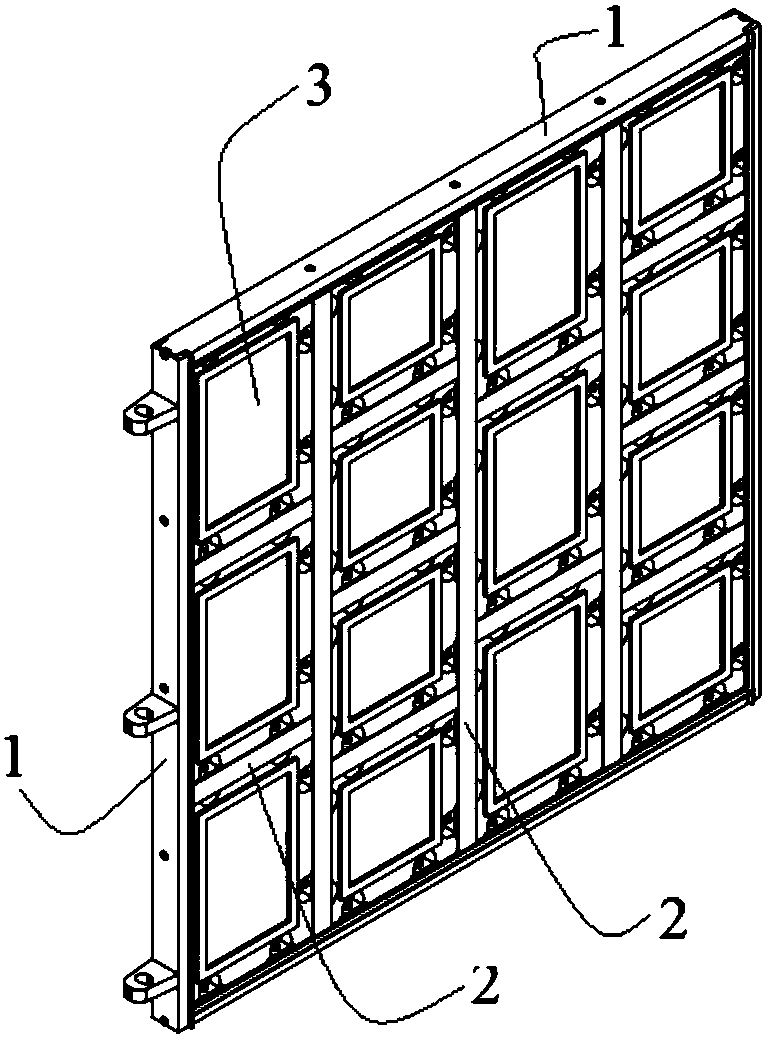

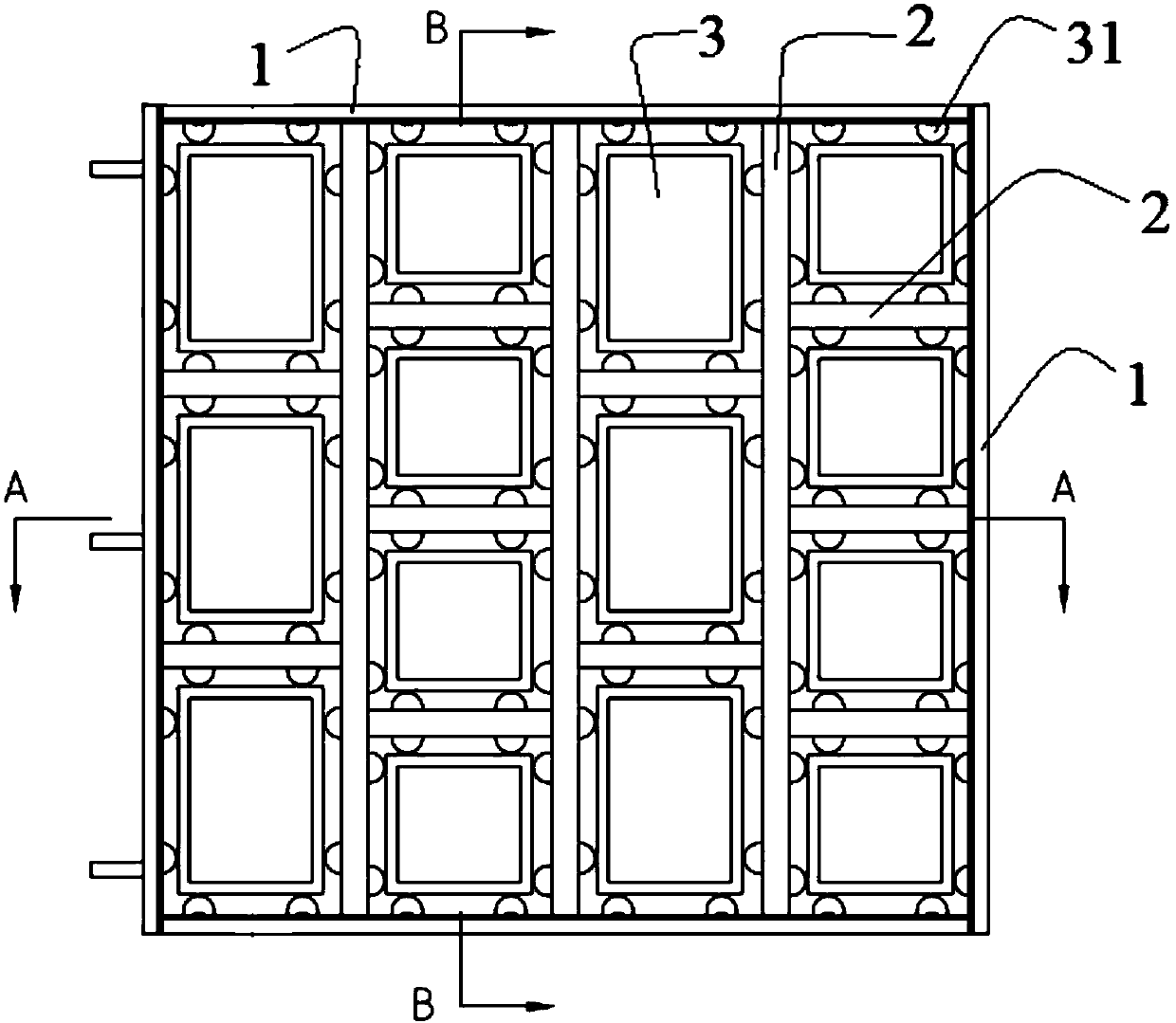

[0047] see Figure 1-28 , the embodiment of the present invention provides a modular door leaf of an assembled civil air defense door, which includes: a plurality of frame channel steels 1 , a plurality of I-beams 2 and a plurality of prefabricated modules 3 .

[0048] Specifically, a plurality of frame channel steels 1 are sequentially connected end to end to form a closed ring to serve as the frame of the door leaf 400 , such as a rectangular ring or a circular ring. The frame channel steel 1 is formed with a groove, and the direction of the groove is to point to the center of the airtight ring, that is, the groove formed by each frame channel steel 1 is located on the same side of the airtight ring (that is, the bottom of the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com