Rubber damper with presettable initial rigidity

A technology of initial stiffness and damper, which is applied in the direction of building components, earthquake resistance, building types, etc., can solve the problems of increasing the volume of earthquake-resistant structures, poor tensile capacity, inability to stretch, energy consumption and vibration reduction, etc., to reduce volume and reduce The Effect of Seismic Isolation Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

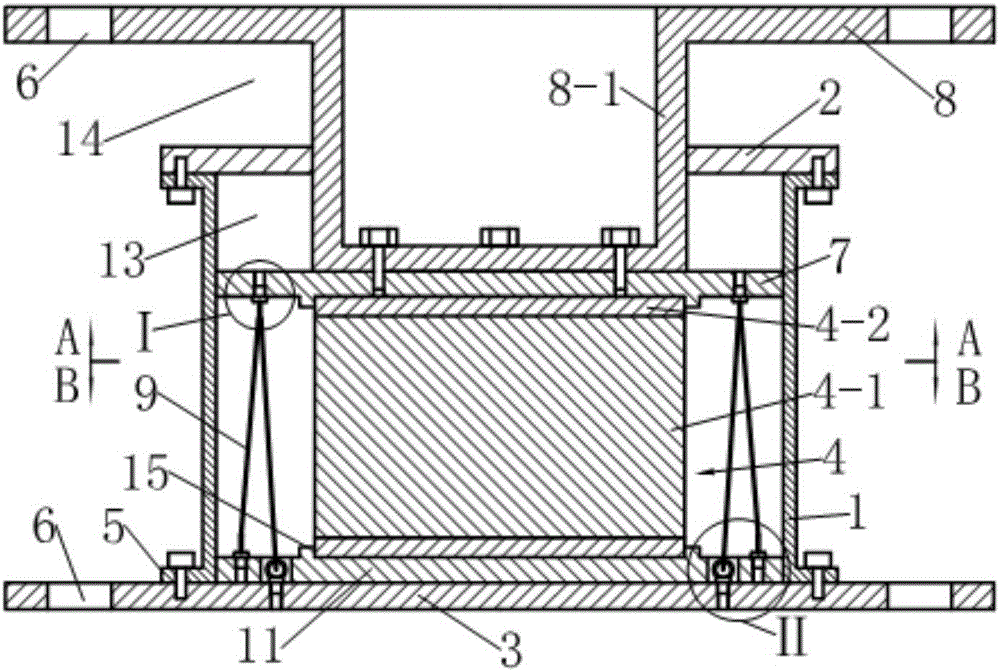

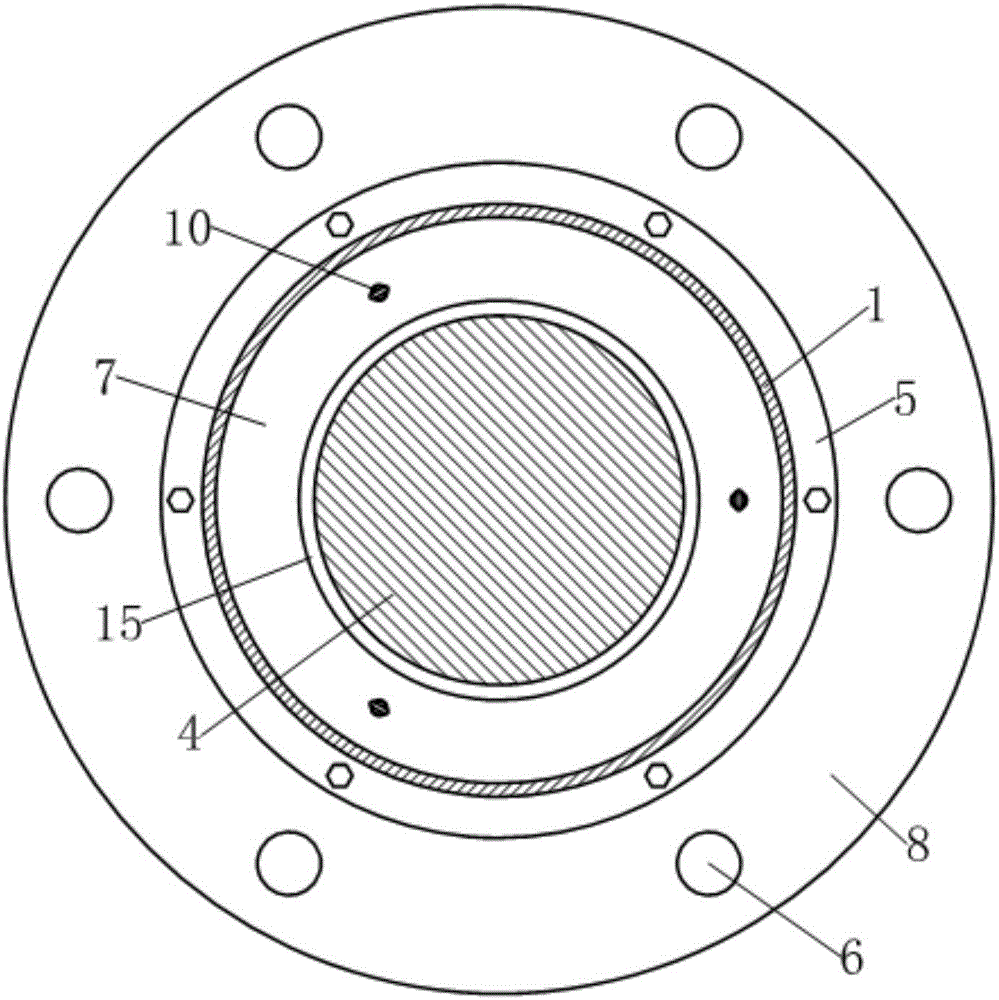

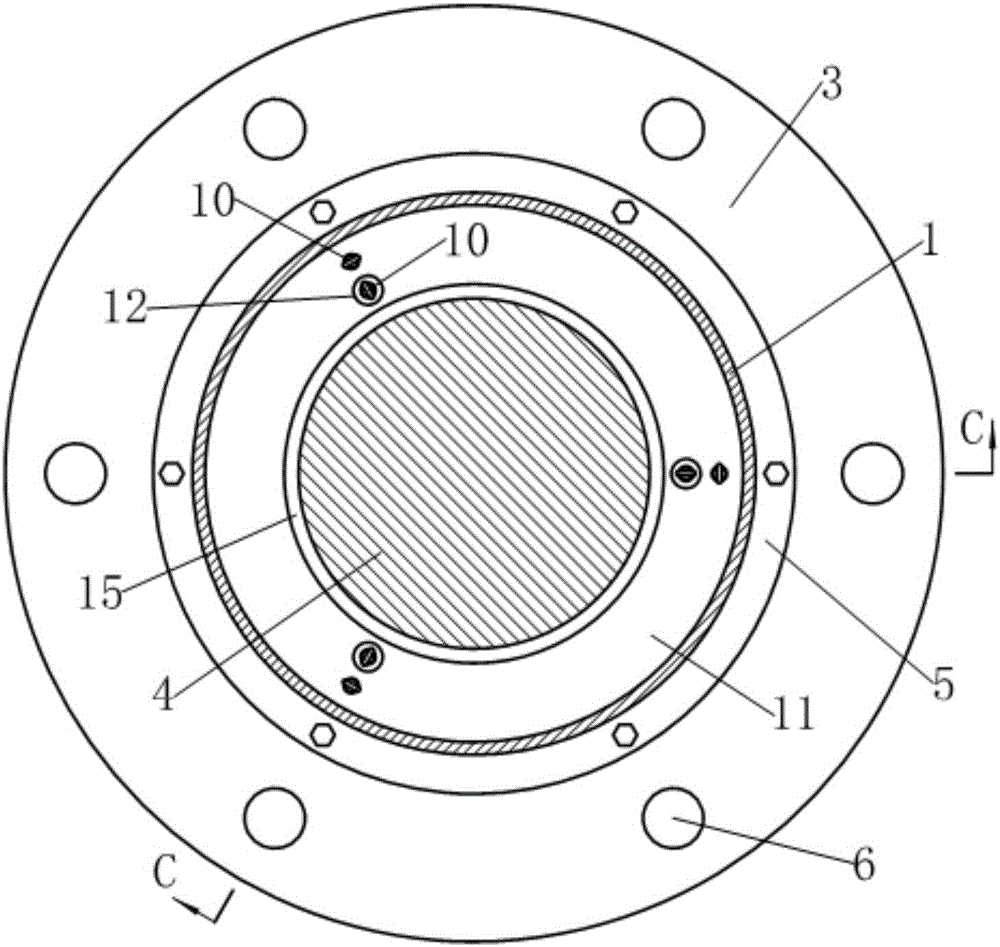

[0040] see Figure 1-5 , the damper described in this example is a vertical shock-isolation device (also known as a vertical shock-isolation support) for building anti-seismic, which includes a guide sleeve 1, a first end cover 2, a second end cover 3 , Rubber shock-isolating pad 4 and back pressure device.

[0041] see Figure 1~3 , the guide sleeve 1 is in the shape of a circular tube, and its two ends extend radially outward to form a flange 5 . The first end cover 2 is connected to the flange 5 on the upper end of the guide sleeve 1, and the center is provided with a guide hole; the second end cover 3 is disc-shaped, and the surrounding edges are provided with mounting holes 6. The guide sleeve 1 is fixed on the middle part of its upper surface by the flange plate 5 provided at the lower end.

[0042] see Figure 1~3 , the driving member is composed of a dynamic pressure plate 7 and an upper connecting plate 8, wherein the edge of the upper connecting plate 8 is provid...

example 2

[0055] see Figure 6-11 , the damper described in this example is also a vertical shock-isolation device for building anti-seismic, and on the basis of example 1, the following improvements are mainly made: (1) the pre-compressed steel wire rope 9 is increased by three to four; (2) replace the eye screw 10 as the wire rope changing element with a U-shaped member 17; (3) replace the eye screw 10 at the other end of the fixed preloaded wire rope 9 with a wire rope self-locking anchor 16; (4 ) thicken the middle part of the second end cover 3 and bulge upwards to form an inverted washbasin shape, so as to install the wire rope self-locking anchor 16; (5) correspondingly change the described back pressure device to:

[0056] The anti-pressure device consists of four pre-compressed steel wire ropes 9, four U-shaped members 17 as wire rope direction-changing elements, a floating counter-pressure steel plate 11, four eyebolts 10 for fixing one end of the pre-compressed steel wire rop...

example 3

[0066] see Figures 12 to 14 , this example is a damper used for seismic reinforcement of building structures, the damper includes a guide sleeve 1, the two ends of the guide sleeve 1 are respectively fixed with a first end cover 2 and a second end cover 3, and a rubber septum is arranged inside Vibration pad 4, a driving member extends from the center of the first end cover 2 at one end of the guide sleeve into the guide sleeve 1 and presses on the rubber shock-isolating pad 4; The first driving rod 18 connected into one body is formed, the end of the first driving rod 18 is provided with a connecting ring 18-1 threadedly butted together with it, and the connecting ring 18-1 is provided with a hinged hole 19, so Described movable platen 7 is dynamically matched with guide sleeve 1. The outer diameter of the rubber vibration-isolating pad 4 is smaller than the inner diameter of the guide sleeve 1, and an annular space is formed between the two.

[0067] see Figure 12 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com