Wide sleeper plate sticking type ballast track

A pillow board and track technology, which is applied in the field of wide pillow board bonded ballast track, can solve the problems of long repair time, inadaptability, difficulty, etc., achieve small maintenance and repair workload, improve overall life, and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

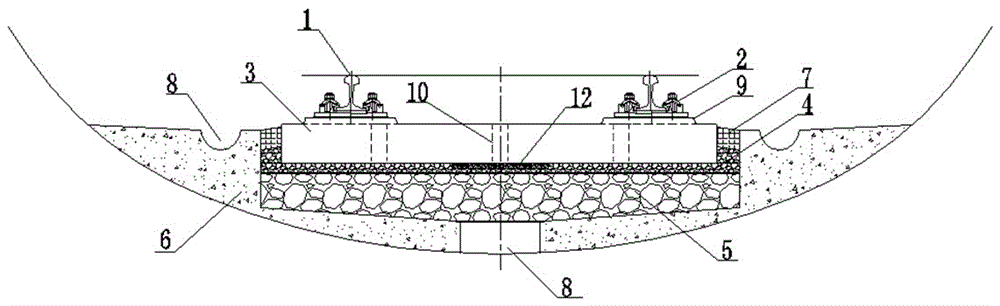

Embodiment approach 1

[0039] Embodiment 1 of the ballast trough of the present invention: When the line is located in a single-line tunnel or other structures with limited space on both sides, the inner film is directly erected at the inner contour line of the ballast trough, and the ballast is poured using the inner contour of the tunnel wall as the outer film Groove concrete, water ditches can be set on the left and right sides and bottom of the ballast groove respectively.

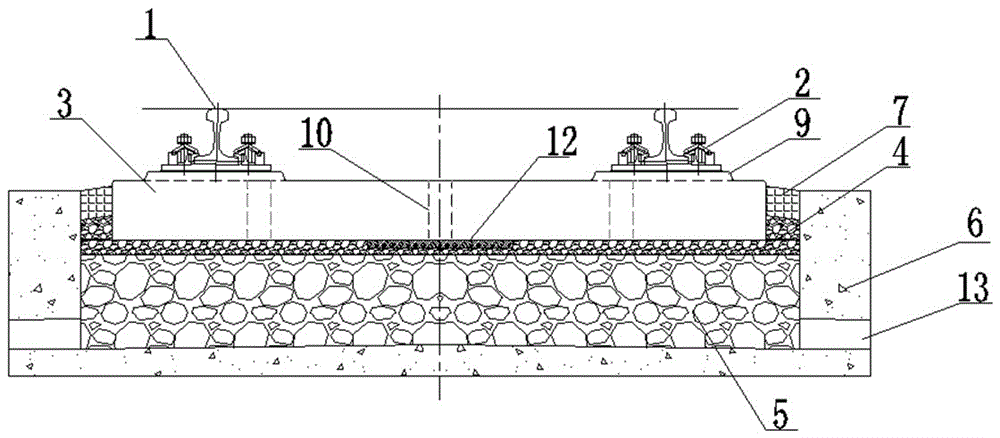

Embodiment approach 2

[0040] Embodiment 2 of the ballast trough of the present invention: when the line is located on both sides of the space without limitation, the inner and outer formworks shall be erected and the ballast trough concrete shall be poured according to the design outline of the ballast trough, and drains may be installed on both sides of the bottom of the ballast trough. water hole.

[0041] The ballast ballast of the present invention is Class I or extra-grade crushed stone ballast, and the ballast needs to be washed with water and dried or dried before being put on the road. During construction, mark the design elevation of ballast and small-grain melon seeds on the ballast groove with ink line or paint. Pave gravel ballast according to the virtual paving thickness obtained from the experiment to ensure that the elevation of the compacted gravel ballast reaches the design level, and the error should meet the design requirements.

[0042] The small-grain melon seed stone of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com