A mold changing device for the lower mold of the folding mechanism of the bag sticking machine

The technology of a bag sticking machine and a rotating mechanism is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, etc. It can solve the problems that the lower mold cannot be pulled out from the pocket, high labor cost, and low efficiency, etc., and achieves simple structure and low cost. The effect of labor intensity and ease of retraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

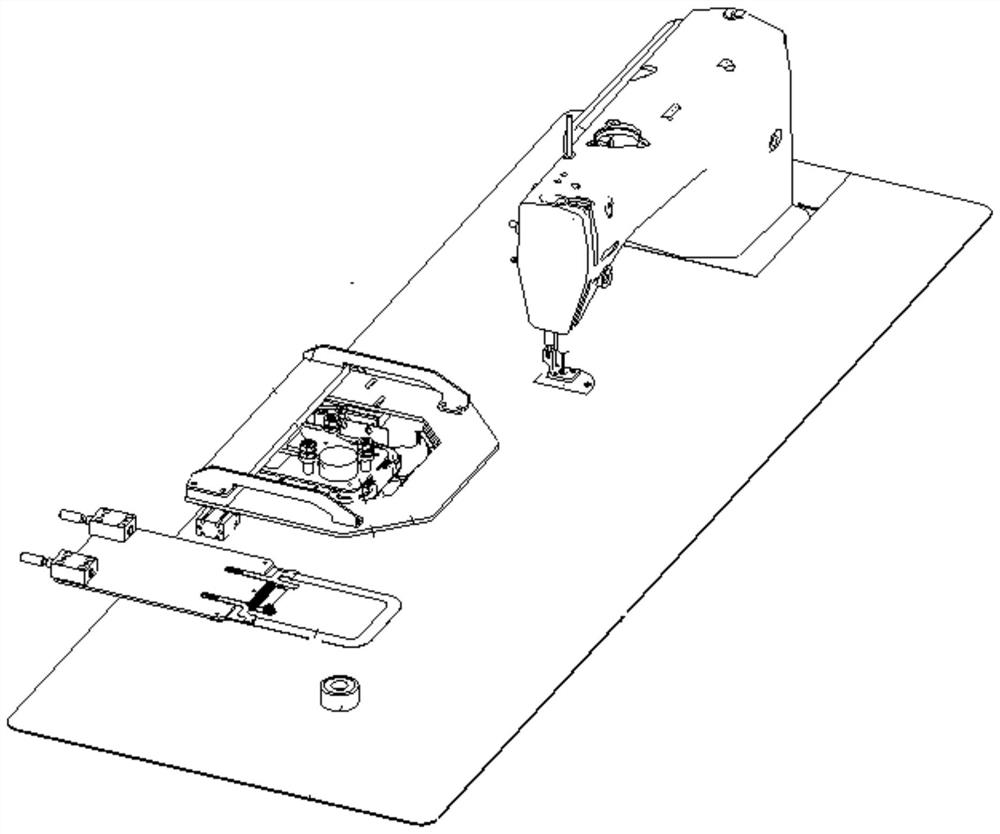

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

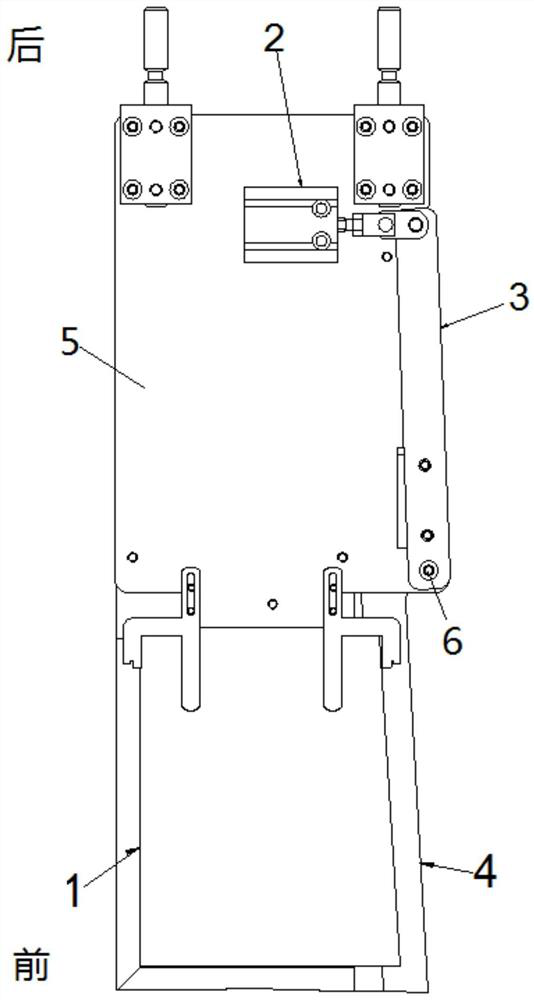

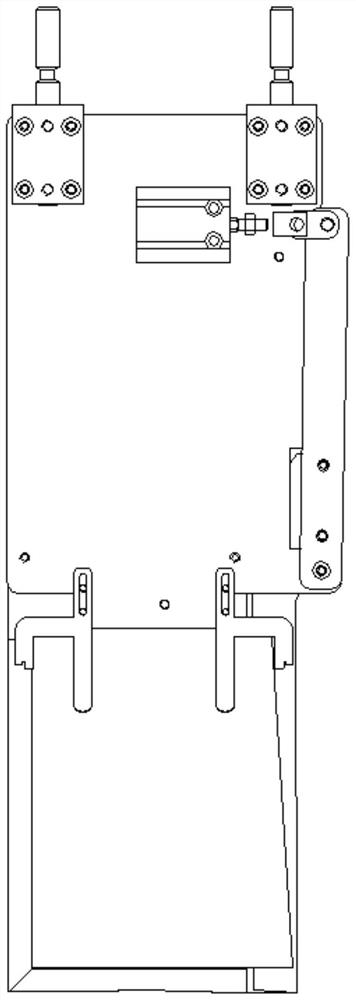

[0027] see Figure 1-2 , a mold changing device for the lower mold of the hemming mechanism of the bag sticking machine, the lower mold of the hemming mechanism includes a connecting plate 5, and the front part of the connecting plate is fixedly connected to the lower mold 1 for inserting into the pocket cloth below, and the connecting plate 5 At least one side is provided with a swing arm 3, and the swing arm 3 is fixedly connected to the die-changing sheet 4, and the connection part has a fixed rotating mechanism 6, and the swing arm 3 is fixedly connected to the push rod of the power source 2, and the power source During action, the swing arm 3 drives the mold changing piece 4 to swing around the rotating mechanism 6. When folding the bag, the front part of the mold changing piece 4 opens outwards, and when the mold is demoulded, the front p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com